For any children's wear brand owner, the word "supply chain" can bring both hope and stress. You hope it delivers quality products on time. But you stress about hidden risks that could harm your brand. In today's market, simply knowing your supplier's name is not enough. True security and competitive advantage come from complete transparency.

Traceability is no longer a luxury; it's a fundamental requirement for building a trustworthy and successful children's clothing brand. It directly answers critical concerns about product safety, ethical production, and brand integrity, which are top priorities for your customers and, ultimately, for your bottom line.

Understanding the journey of your garments, from raw material to finished product, is the key to managing these risks effectively. Let's explore why investing in a traceable supply chain is one of the smartest decisions you can make for your business.

What are the risks of an opaque children's clothing supply chain?

An unclear supply chain is like driving with a foggy windshield. You might move forward, but you can't see the dangers ahead. For children's wear, the risks are particularly high. Hidden problems can lead to product recalls, legal trouble, and irreversible damage to your brand's reputation.

The primary risk of an opaque supply chain is the loss of control. You cannot guarantee quality, safety, or ethical standards if you do not know where and how your products are made. This exposes your business to significant financial and reputational hazards.

When you lack visibility, you are essentially trusting multiple unknown parties with your brand's most valuable asset: its reputation.

How can hidden suppliers impact your product quality?

Your brand promises a certain level of quality. But if a sub-contractor you didn't approve enters the picture, that promise can break. We have seen cases where brands received finished goods that did not match their approved samples. The reason? A main supplier, facing capacity issues, secretly outsourced production to a cheaper, lower-standard factory.

This practice directly threatens your product's integrity. The unapproved factory may use inferior fabrics or skip crucial quality control steps. For example, they might use dyes that do not meet international safety standards like OEKO-TEX®, or they might ignore strict flammability standards for children's sleepwear. You end up paying for a product that could fail safety tests and disappoint your customers. Without traceability, you have no way to prevent this.

What financial and legal dangers do you face?

The consequences extend beyond unhappy customers. If a component of your clothing, like a button, comes from an unvetted source and causes a choking hazard, your company is liable. The costs of a product recall are enormous. You must manage logistics, offer refunds, and face potential lawsuits.

Furthermore, customs authorities in the US and Europe require accurate documentation of origin. If your supply chain is complex and unclear, you might accidentally violate customs compliance rules, leading to seized shipments, hefty fines, and delays. An opaque chain also makes you vulnerable to accusations of unethical labor practices, which can trigger consumer backlash and legal action under regulations like the Uyghur Forced Labor Prevention Act (UFLPA). The financial impact can be devastating.

How does supply chain transparency ensure safety and compliance?

Transparency is your best defense against uncertainty. It transforms your supply chain from a black box into a clear, manageable process. For children's products, where safety is non-negotiable, this clarity is your strongest selling point to cautious parents.

A transparent supply chain ensures safety and compliance by allowing you to verify every step of production. You can confirm that all materials and manufacturing processes adhere to the strictest international standards, giving you and your customers absolute peace of mind.

When you can trace a garment back to its source, you build a foundation of trust that protects everyone involved.

Why is material traceability critical for children's wear?

It all starts with the materials. For children's sensitive skin, using safe, high-quality fabrics is essential. We implement a rigorous fabric testing protocol for every batch of material we source. But we go a step further by demanding documentation from our textile mills.

This means we can provide you with certificates proving that our cottons are GOTS certified organic cotton, ensuring no harmful pesticides were used. We can trace the dyes back to suppliers who comply with REACH standards. This level of detail is not just about checking a box. It is about ensuring that every piece of clothing that reaches a child is safe from the inside out. This documented trail is invaluable during third-party audits or if you ever need to verify claims for your marketing.

How does transparency simplify compliance with international standards?

The regulatory landscape for children's apparel is complex and constantly evolving. From CPSIA in the US to EN 71 in Europe, the requirements are stringent. A transparent supply chain makes compliance a manageable, integrated part of production, not a last-minute panic.

Because we map our entire supply chain, we can quickly gather all necessary documentation for any component. Need a report on phthalate content for a PVC-free claim? We can provide it because we know exactly which factory supplied the plastic for the prints. This proactive approach prevents shipping delays at ports. It also future-proofs your business against new regulations. When a new standard is introduced, we can efficiently audit our chain to ensure full compliance, saving you time and resources.

Can a traceable supply chain become your competitive advantage?

Beyond risk mitigation, a transparent supply chain is a powerful tool for growth. Today's consumers, especially parents, are increasingly making purchasing decisions based on a brand's values and integrity. They want to know the story behind the products they buy for their children.

Absolutely. A traceable supply chain is a significant competitive advantage. It allows you to build a brand story rooted in ethics, quality, and trust, which resonates deeply with modern consumers and sets you apart in a crowded marketplace.

This transparency is not just a cost of doing business; it's an investment in your brand's equity and long-term customer loyalty.

How do you build a stronger brand story?

"Ethically made" and "responsibly sourced" are powerful marketing phrases, but they are empty without proof. A traceable supply chain gives you the evidence to back up your claims. You can share the journey of your products with your customers.

Imagine your website having a section called "Our Story" where you can show photos and videos of the skilled workers at our factory, explain our sustainable manufacturing practices, and display our compliance certificates. This authentic narrative builds an emotional connection with your audience. It tells them that you care not just about profit, but about the impact of your products. This level of honesty fosters incredible brand loyalty and allows you to justify a premium price point.

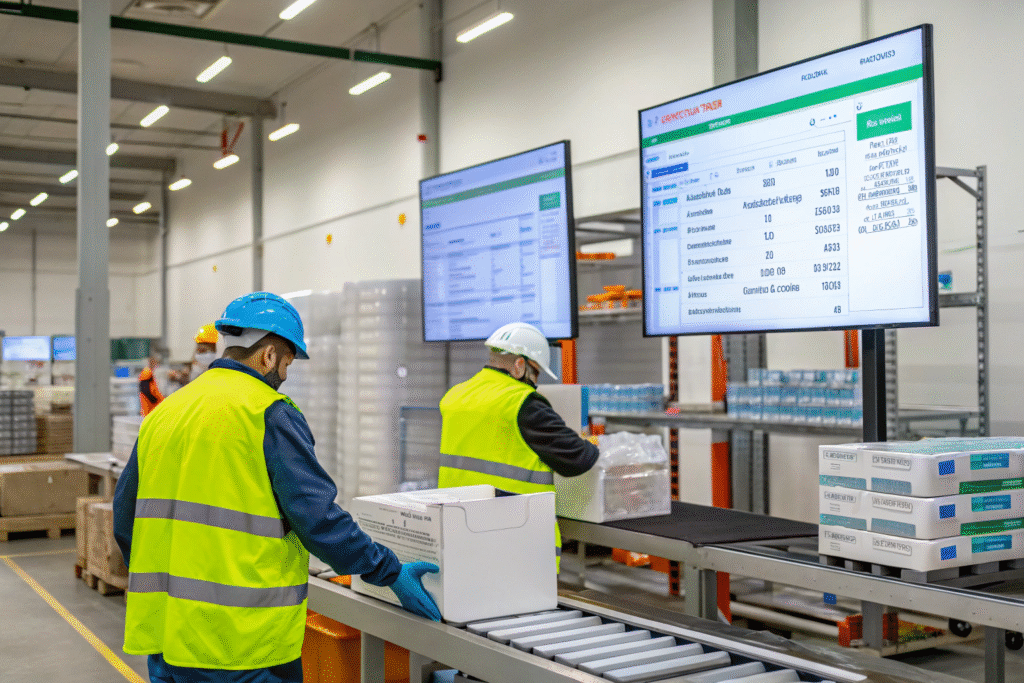

How does transparency improve operational efficiency?

Visibility leads to efficiency. When you have a clear view of your supply chain, you can identify bottlenecks, reduce lead times, and improve planning accuracy. This operational excellence translates directly to your bottom line.

For instance, because we have full control over our production lines and partner network, we can provide you with accurate, real-time updates on your order's status. This prevents the "black hole" effect where orders disappear until they suddenly (or late) arrive at port. Better planning means you can align production with your selling seasons, reducing the risk of missed opportunities and the cost of holding excess inventory. It creates a predictable, reliable partnership that feels more like an extension of your own team.

What should you look for in a transparent manufacturing partner?

Choosing a manufacturer is about more than just price. It's about selecting a partner whose values and operational standards align with your own. The right partner will view transparency not as an inconvenience, but as a core part of their service.

You should look for a manufacturer that proactively offers evidence of their transparency. This includes open communication about their factory, verifiable certifications, robust quality control processes, and a willingness to integrate their systems with your need for visibility.

A trustworthy partner has nothing to hide and everything to gain by being open with you.

What questions about factory audits and certifications should you ask?

Don't be shy. Ask direct questions. A reliable manufacturer will welcome them. Start by asking for proof of their business license and export credentials. Then, dig deeper into their social and quality compliance.

Key questions include:

- "Can you share recent audit reports from independent bodies like SMETA or BSCI?"

- "What specific certifications do you hold for the materials you use, such as GOTS or OEKO-TEX STeP?"

- "Can you provide a detailed map of your production process and your key subcontractors, if any?"

Their answers, and the speed at which they provide documentation, will tell you everything you need to know about their commitment to transparency.

How important is communication and technology in maintaining visibility?

Transparency is built on communication. Your manufacturing partner should assign a dedicated representative, like our Business Director Elaine, who understands your business and is accessible. They should provide regular updates without you having to chase them.

Furthermore, ask about the technology they use. Do they have a system for sharing production status reports? Can they provide photos or videos at key stages of production? At our company, we use a secure online platform where clients can track their order progress, view inspection reports, and access all compliance documents 24/7. This level of integrated communication ensures you are never in the dark.

Conclusion

Tracing your children's clothing supply chain is no longer an optional extra. It is a strategic imperative for any brand serious about quality, safety, and long-term success. From mitigating risks and ensuring compliance to building a powerful brand story and improving efficiency, the benefits of transparency are clear and substantial. It is the foundation upon which trusted brands are built.

The journey toward full supply chain visibility starts with choosing the right partner. If you are looking for a children's wear manufacturer that prioritizes transparency as much as you do, we should talk. We have built our business on the principles of open communication, verifiable quality, and reliable delivery. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can bring transparency and excellence to your next clothing order.