The children's sleepwear market operates under some of the most stringent regulations in the apparel industry. As a manufacturer who has worked with US brands for years, I've seen how these rules shape every aspect of sleepwear production. Parents might wonder why sleepwear receives such special attention compared to other children's clothing categories.

The kids sleepwear market is strictly regulated primarily due to flammability risks during nighttime wear, children's vulnerability in fire situations, and the unique safety hazards posed by loose-fitting garments near ignition sources. These regulations mandate specific fabric treatments, design restrictions, and labeling requirements that distinguish sleepwear from regular clothing and create crucial safety barriers between children and potential fire hazards.

The evolution of these regulations represents one of the most successful consumer safety stories in modern history, dramatically reducing burn injuries and fatalities among children.

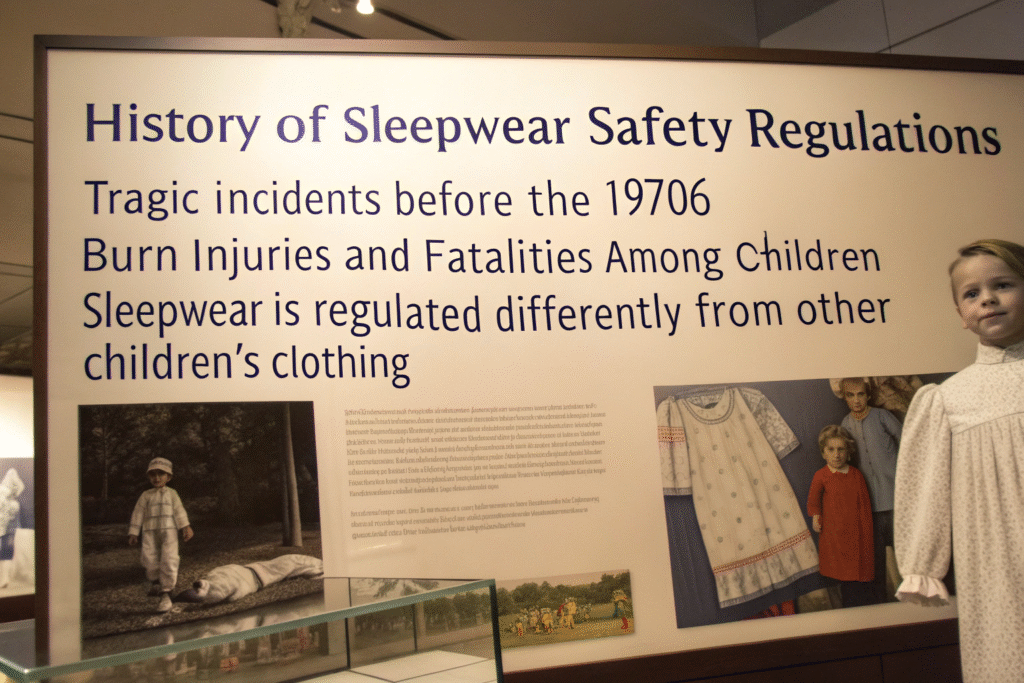

What Are the Historical Reasons Behind Strict Regulations?

The current regulatory framework emerged from tragic historical events. Before the 1970s, sleepwear-related burn injuries and fatalities among children were alarmingly common, prompting government intervention and establishing the foundation for today's safety standards.

Understanding this history explains why regulators treat sleepwear differently from other children's clothing and why compliance is non-negotiable for responsible manufacturers.

How Did Tragic Events Shape Current Standards?

The 1960s saw numerous heartbreaking incidents where children's sleepwear ignited from various household heat sources, leading to severe injuries and fatalities. These tragedies prompted congressional hearings and ultimately resulted in the Flammable Fabrics Act amendments of 1967, which empowered the Consumer Product Safety Commission (CPSC) to establish mandatory flammability standards for children's sleepwear. The statistics from that era revealed an urgent need for intervention that could prevent these preventable accidents.

What Scientific Research Drove Regulatory Changes?

Extensive research conducted by government agencies and independent laboratories demonstrated that certain fabric types, particularly loose-fitting cotton garments, posed significantly higher fire risks than tighter-fitting styles or treated fabrics. Studies showed that children's sleepwear safety required addressing both fabric flammability and design elements that could accelerate fire spread. This research established the scientific basis for distinguishing between sleepwear and daywear through specific safety requirements.

| Historical Period | Key Developments | Impact on Safety |

|---|---|---|

| Pre-1960s | Limited regulation, high use of flammable fabrics | Numerous sleepwear-related burn incidents |

| 1967-1972 | Flammable Fabrics Act amendments, initial standards | First mandatory flammability requirements |

| 1970s-1980s | Refined standards, chemical treatment requirements | Significant reduction in burn injuries |

| 1990s-Present | Ongoing updates, alternative compliance methods | Continued safety improvements with flexibility |

How Do Flammability Standards Protect Children?

Flammability standards form the core of sleepwear regulation, specifically designed to address the unique risks children face while sleeping. These standards create multiple layers of protection through fabric performance requirements and design restrictions.

The regulations recognize that children have limited ability to escape burning clothing and may encounter various ignition sources in residential settings.

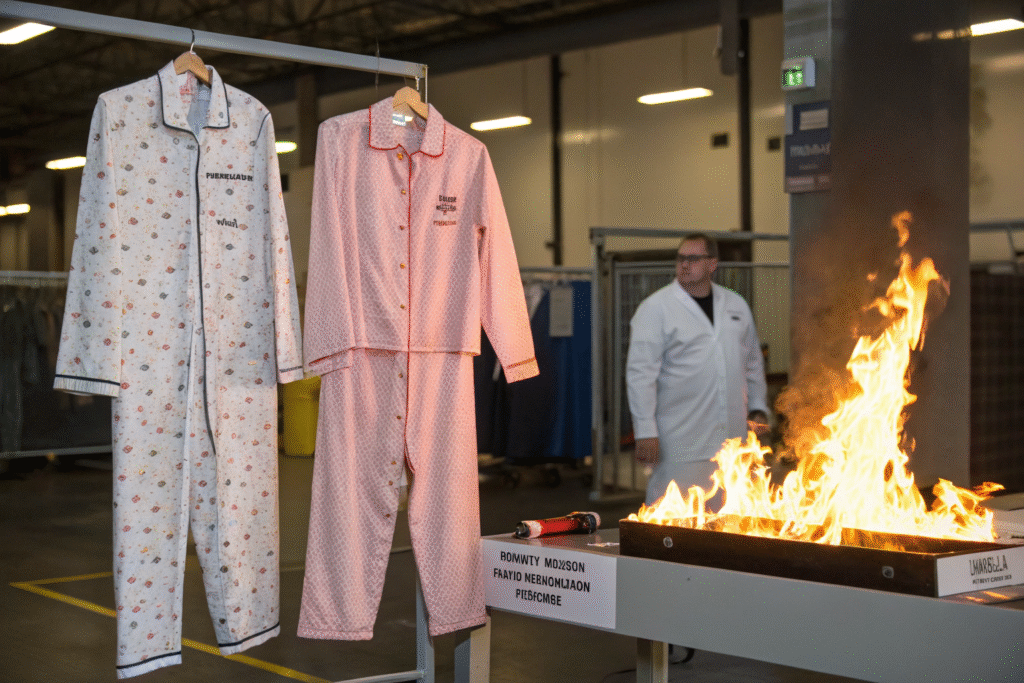

What Are the Specific Flammability Testing Requirements?

All children's sleepwear must pass vertical flame tests that measure how quickly flames spread up the fabric. The ASTM standard testing specifies that fabrics must self-extinguish within a defined timeframe and cannot exceed maximum char lengths. These tests simulate real-world scenarios where clothing might contact flame sources, ensuring that compliant sleepwear won't sustain burning and gives children crucial extra seconds to escape or receive help. The testing protocols are rigorous and repeated across production batches to ensure consistent safety.

Why Are Fabric Treatments and Alternatives Important?

For fabrics that don't naturally meet flammability standards, safe chemical treatments or inherent flame resistance become necessary. While some manufacturers use flame retardant chemicals that meet safety standards, many now prefer inherently flame-resistant fibers like polyester that provide permanent protection without chemical treatments. At our factory, we primarily use polyester and other synthetic blends that naturally meet flammability requirements, eliminating concerns about chemical treatments while maintaining permanent safety through the garment's lifespan.

What Design and Labeling Requirements Apply?

Beyond fabric flammability, sleepwear regulations extend to physical design elements and mandatory labeling that ensures proper use and identification. These requirements work together with flammability standards to create comprehensive protection.

Design restrictions address how garments interact with potential ignition sources, while labeling ensures consumers can identify compliant sleepwear.

How Do Design Restrictions Enhance Safety?

Sleepwear design regulations focus on eliminating loose-fitting elements that could easily contact flame sources or create air pockets that accelerate burning. The standards specify maximum dimensions for sleepwear length and width measurements relative to size, ensuring a snug fit that reduces fire risk. These design rules apply differently to various age groups, with infants (0-9 months) having different requirements than older children, recognizing their different mobility and sleeping environments.

What Information Must Appear on Labels?

Permanent labels must clearly indicate compliance with flammability standards, typically stating "Meets CPSC Flammability Standards for Children's Sleepwear." Additionally, care labeling requirements must include instructions that maintain the garment's flame resistance, such as avoiding certain laundry additives that could reduce effectiveness. These labels serve both regulatory compliance and consumer education functions, helping parents identify properly tested sleepwear and maintain its safety features through repeated washings.

How Do Regulations Vary by Age Group?

Sleepwear regulations recognize that children of different ages face different risks and have varying abilities to escape dangerous situations. The standards establish distinct requirements for three primary age categories, creating appropriate protection levels for each developmental stage.

This age-based approach ensures that regulations address the specific risks each group faces while allowing practical design solutions.

What Standards Apply to Infant Sleepwear?

For infants 0-9 months, all sleepwear must be snug-fitting regardless of fabric type, recognizing that infants have minimal mobility and cannot escape burning clothing. The size requirements for infant sleepwear specify very tight dimensional tolerances to ensure close-fitting garments that won't easily contact flame sources. This approach acknowledges that infants spend most of their time in controlled sleeping environments but still need protection from potential fire hazards.

How Do Requirements Change for Older Children?

As children grow older and gain more mobility, the regulations offer more flexibility while maintaining safety. For children 9 months through 6 years, sleepwear must be either snug-fitting or flame-resistant if loose-fitting. For the 7-14 age group, older children's sleepwear regulations allow more style variety while still requiring that all garments meet the same flammability standards through either fit or fabric selection. This graduated approach balances safety with practical clothing needs as children develop.

Conclusion

The strict regulation of children's sleepwear represents a vital consumer protection success story, dramatically reducing burn injuries and saving countless young lives. These regulations address very real risks through comprehensive approaches covering fabric performance, design elements, labeling, and age-appropriate requirements. For manufacturers, understanding and meticulously implementing these standards is not just about legal compliance—it's about moral responsibility to protect the most vulnerable consumers.

At Shanghai Fumao Clothing, we maintain rigorous testing protocols and design standards to ensure all our children's sleepwear exceeds regulatory requirements. We help our US partners navigate these complex regulations while creating comfortable, attractive sleepwear that parents can trust. If you're looking for a manufacturing partner who prioritizes safety without compromising on quality or style, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create sleepwear that protects children while giving parents peace of mind.