In my decades of experience running a children's clothing manufacturing business, I've learned that the specification sheet is the single most important document that determines whether a production run succeeds or fails. Many startups and even established brands underestimate its importance, only to discover costly mistakes when it's too late.

A detailed specification sheet is vital for manufacturing because it serves as the universal communication tool that eliminates ambiguity, prevents costly errors, ensures quality consistency, and establishes clear accountability throughout the production process. It transforms creative vision into technical reality by providing precise measurements, material requirements, construction details, and quality standards that everyone from designers to factory workers can follow accurately.

Without a comprehensive spec sheet, you're essentially hoping your manufacturer can read your mind - and that's a risk no serious brand should take.

How Does a Spec Sheet Prevent Costly Errors?

The financial implications of inadequate specification sheets are staggering. I've seen brands lose thousands of dollars on production runs because of missing or unclear specifications that led to wrong materials, incorrect sizing, or construction flaws.

A comprehensive spec sheet acts as your first line of defense against manufacturing mistakes that can destroy your profit margins and damage your brand reputation.

What Are the Most Common Costly Mistakes?

The most expensive errors typically occur in areas where assumptions replace explicit instructions. Incorrect fabric specifications can lead to using materials that don't meet safety standards or performance requirements. Missing construction details often result in weak seams, improper finishing, or functionality issues. At our factory, we've received spec sheets that failed to specify stitch types, leading to garments that couldn't withstand children's active wear. These oversights become apparent only after production completes, when correction costs are highest.

How Does Precision Save Money?

Detailed specifications eliminate the need for expensive revisions and remakes. When every element is clearly documented - from precise measurement tolerances to exact color standards - manufacturers can execute accurately the first time. This precision reduces sampling cycles, minimizes material waste, and prevents production delays. Brands that invest time in creating thorough spec sheets typically see 30-50% fewer quality issues and significantly faster time-to-market for their collections.

| Specification Element | Common Error Without Clear Specs | Financial Impact | Prevention Method |

|---|---|---|---|

| Fabric Composition | Wrong material substitution | Complete production loss | Detailed technical sheets with testing requirements |

| Measurements | Inconsistent sizing across production | High return rates | Grade rules with tolerance limits |

| Color Standards | Color mismatches between pieces | Unsalable inventory | Physical lab dips and digital color codes |

| Construction Details | Weak seams, improper finishing | Customer complaints and returns | Stitch-per-inch specifications and reinforcement details |

How Does a Spec Sheet Ensure Quality Consistency?

Quality consistency separates successful brands from those that struggle with customer satisfaction and returns. A detailed spec sheet provides the framework for maintaining uniform quality across all production batches and over multiple seasons.

Consistency is particularly crucial in children's wear, where safety, durability, and comfort standards must be maintained across every garment produced.

What Quality Elements Require Precise Specification?

Every aspect of garment construction needs clear quality benchmarks. Stitch density requirements ensure seam strength, while precise tolerance levels maintain consistent sizing. Fabric performance standards - including colorfastness, pilling resistance, and shrinkage limits - must be explicitly stated. At our factory, we require brands to specify even seemingly minor details like thread type and button attachment strength, as these elements significantly impact the garment's longevity and safety.

How Does Documentation Support Quality Control?

A comprehensive spec sheet provides the foundation for effective quality control processes. It enables systematic inspection protocols where each garment element can be checked against established standards. Without this documentation, quality control becomes subjective and inconsistent. We train our QC teams to use spec sheets as their primary reference, ensuring every inspection is objective, measurable, and consistent across different inspectors and production batches.

How Does a Spec Sheet Facilitate Communication?

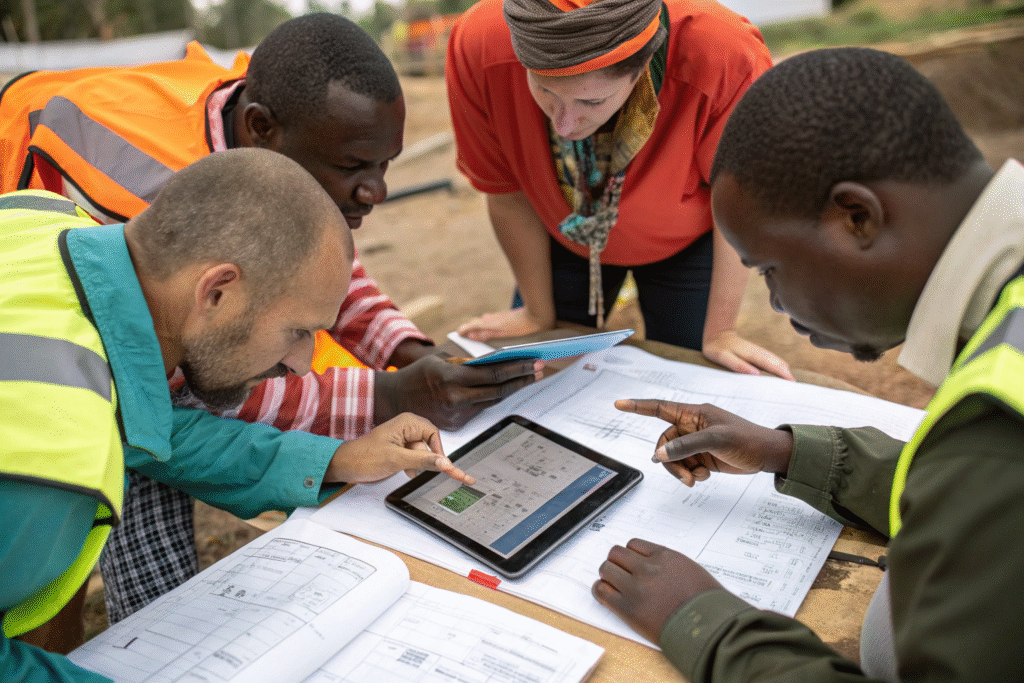

Manufacturing involves multiple stakeholders across different departments, languages, and cultural contexts. The spec sheet serves as the universal language that ensures everyone understands exactly what needs to be produced.

Clear communication prevents misunderstandings that can lead to production errors, timeline delays, and cost overruns.

How Does It Bridge Language Barriers?

In global manufacturing, technical specifications transcend language differences. Standardized technical drawings, internationally recognized measurement systems, and visual references create understanding regardless of native language. While our team is fluent in English, we always insist on detailed spec sheets because they eliminate any potential misinterpretation of verbal instructions or incomplete emails. The visual nature of technical flats and detailed callouts ensures nothing gets lost in translation.

What Role Does It Play in Supplier Relationships?

Detailed spec sheets establish professional credibility and set clear expectations with manufacturing partners. When brands provide comprehensive documentation, it demonstrates they understand manufacturing complexities and respect their supplier's time and expertise. This professionalism fosters stronger supplier relationships built on mutual understanding and clear communication. Manufacturers are more likely to prioritize clients who provide thorough specifications because they know these projects will run smoothly with fewer complications.

How Does a Spec Sheet Protect Your Business?

Beyond production benefits, a detailed specification sheet provides crucial legal and business protection. It serves as an objective reference point for resolving disputes and ensures your intellectual property and quality standards are properly documented.

This documentation becomes particularly valuable when dealing with production issues, quality disputes, or considering manufacturer changes.

How Does It Establish Legal Accountability?

A signed specification sheet becomes a binding document that defines expected outcomes. If manufactured products don't match agreed specifications, you have clear legal grounds for requesting corrections, compensation, or rejecting shipments. This protection is especially important when working with new manufacturing partners or when production occurs overseas. The spec sheet provides objective criteria that supersede subjective opinions about quality or execution.

Why Is It Essential for Brand Protection?

Your specification sheet documents the unique elements that define your brand identity. From proprietary construction techniques to special material treatments, these details represent your brand's intellectual property. Comprehensive documentation ensures that if you need to change manufacturers, your new partner can replicate your products exactly. It also prevents manufacturers from making unauthorized substitutions that could compromise your brand reputation for quality and consistency.

Conclusion

A detailed specification sheet is not just paperwork - it's the foundation of successful manufacturing relationships and product excellence. It transforms creative vision into producible reality while protecting your investment, ensuring quality consistency, and facilitating clear communication across all stakeholders. The time invested in creating comprehensive specifications pays dividends through smoother production, fewer errors, consistent quality, and stronger manufacturer relationships.

At Shanghai Fumao Clothing, we've developed sophisticated specification templates that help our partners document every critical detail of their children's wear designs. Our experience has shown that brands who prioritize detailed specifications achieve better production outcomes and faster business growth. If you want to ensure your next manufacturing project runs smoothly from concept to delivery, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build the detailed specifications that will guarantee your manufacturing success.