As a children's clothing manufacturer, I see a big shift in what brands ask for. Today, it's not just about cute designs. It's about responsibility. Many of our US-based partners now want to know about the materials we use, especially recycled ones. This is a core part of our business at Fumao Clothing. We help brands meet modern consumer demands.

Recycled materials play a crucial role in modern kids' apparel production by directly addressing consumer demand for sustainability, enhancing brand image, and providing a practical path to creating safer, high-quality garments without compromising on style or durability. This evolution is central to how we manufacture for the American market, ensuring every piece is built to last and designed with the future in mind.

How Do Recycled Materials Improve Kids' Clothing Quality?

Many buyers worry that "green" means less durable. In my experience, the opposite is true. Using recycled materials often forces a focus on superior quality control from the start. For brands like yours, sensitive to quality, this is a key benefit.

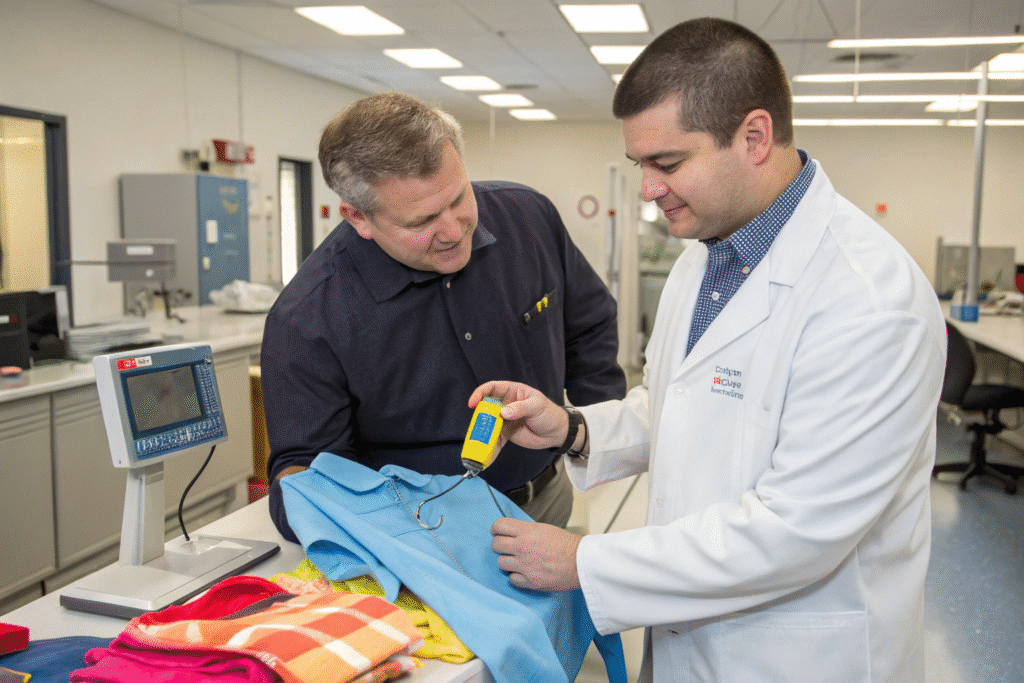

Recycled materials can significantly improve kids' clothing quality by offering enhanced durability, superior safety profiles, and consistent performance, often surpassing their virgin counterparts when sourced and processed correctly. High-quality recycled fabrics are subjected to rigorous testing, resulting in garments that withstand the rough-and-tumble of child's play while adhering to strict international safety standards.

What Are The Performance Benefits Of Recycled Fabrics?

The performance of recycled polyester (rPET) is a great example. It shares all the technical benefits of virgin polyester, like moisture-wicking and color fastness, but with a smaller environmental footprint. For baby apparel, which requires frequent washing, this is vital. We use certified recycled fabrics that ensure these properties are built-in. This aligns with the need for products that can handle real-life use. You can learn more about the properties of these materials from the Sustainable Apparel Coalition, which sets industry standards.

How Does Sourcing Recycled Materials Enhance Supply Chain Control?

Sourcing recycled materials pushes for a more transparent and resilient supply chain. We track our recycled yarns from trusted suppliers, which gives us, and you, better control. This process minimizes the risk of delays and ensures consistent quality across large orders. It directly addresses the pain point of unreliable suppliers. This controlled approach is part of our DDP (Delivered Duty Paid) service model, where we manage the entire process, reducing complexity for you.

Are Recycled Materials In Kids Wear Safe And Certified?

Safety is the number one priority in kids' wear. Any new material, recycled or not, must meet the highest benchmarks. As a factory serving the US and Europe, we never compromise on this.

Yes, certified recycled materials used in kids' wear are completely safe, provided they come with verifiable certifications that guarantee the absence of harmful substances and compliance with global regulations. We insist on materials that are certified to Oeko-Tex Standard 100 or have Global Recycled Standard (GRS) certification, ensuring every step from source to fabric is safe for children.

What Certifications Should I Look For In Recycled Apparel?

When you source, you must look for specific, verifiable certifications. The most important ones are:

| Certification | Focus | Why It Matters for Your Brand |

|---|---|---|

| Global Recycled Standard (GRS) | Track recycled content | Verifies the actual % of recycled material, building consumer trust. |

| Oeko-Tex Standard 100 | Product safety | Tests for harmful substances, ensuring the final garment is safe for kids. |

| GOTS (Global Organic Textile Standard) | Organic & Recycled | Covers both organic farming and processing of natural recycled fibers like cotton. |

These documents prove a product's safety and sustainability claims. We provide these certificates for every order, solving the pain point of suppliers who might falsify documents.

How Can I Verify The Authenticity Of A Supplier's Certifications?

Verifying certifications is straightforward. Always ask for the certificate number and check it on the certifying body's official website. For example, you can verify an Oeko-Tex certificate directly on their portal. We encourage all our partners to do this. It builds the trust that is essential for a long-term partnership. This simple step protects your brand and gives you peace of mind. The American Apparel & Footwear Association (AAFA) also provides resources on responsible sourcing.

What Is The Cost Impact Of Using Recycled Materials?

The cost question is always top of mind. Initially, recycled materials can be more expensive. However, viewing this only as a cost increase is a mistake. It's an investment in your brand's value.

The cost impact of using recycled materials is evolving; while premium recycled fabrics can have a higher upfront cost, they offer long-term value through enhanced brand perception, customer loyalty, and resilience against volatile virgin material prices, making them a competitively priced option in the mid-to-high segment. Our efficient production lines help manage these costs, offering you competitive pricing.

How Does The Pricing Compare To Conventional Fabrics?

The price gap between recycled and conventional fabrics is narrowing. Recycled polyester (rPET) is now often price-competitive. Recycled cotton might still carry a premium due to the complex processing involved. We help you navigate these choices. We find the right material that fits your budget and quality expectations, ensuring you get the best value without surprising cost overruns.

Can Using Recycled Materials Actually Increase My Profit Margins?

Absolutely. Marketing your use of certified recycled materials allows you to command a higher price point. Modern consumers, especially in North America, are willing to pay more for sustainable products. This directly boosts your profit margins. It transforms your sourcing cost into a powerful marketing tool. This strategy aligns perfectly with your business model of adding value before distribution in the USA.

How To Source Recycled Kids Wear From A Reliable Supplier?

Finding a supplier who can deliver on both quality and sustainability promises is the final challenge. It's about more than just finding a manufacturer; it's about finding a partner.

To source recycled kids wear reliably, partner with a manufacturer that has verifiable certifications, transparent communication protocols, and a proven track record of on-time delivery for the US market, ensuring they can translate your sustainability goals into a quality product consistently. This is where our decades of experience and direct, efficient communication make a difference.

What Questions Should I Ask A Potential Manufacturer?

You must ask direct questions. Don't just ask if they have recycled materials. Ask for the specific certification numbers. Ask about their minimum order quantities (MOQs) for custom recycled apparel. Inquire about their lead times and how they handle quality control for these specific fabrications. Their answers will reveal their expertise and reliability. This proactive approach eliminates the inefficiency you've experienced with other sales reps.

How Can I Ensure Consistent Quality And On-Time Delivery?

Consistency comes from a supplier's systems. We have five dedicated production lines that allow us to schedule and monitor your order closely. Our DDP service means we take ownership of the entire logistics process, drastically reducing the risk of delayed shipments and you missing your selling season. We provide regular production updates, so you are never in the dark. This end-to-end control is what makes a supplier truly reliable.

Conclusion

The role of recycled materials in kids' apparel is no longer a niche trend. It is a fundamental shift in how quality, safe, and profitable children's clothing is made. From enhancing product durability and ensuring safety through certifications to improving your brand's market position and margins, recycled materials offer a compelling value proposition. The key to unlocking this value lies in partnering with a manufacturer that has the expertise, certifications, and reliable systems to bring your vision to life.

If you are ready to explore how recycled materials can elevate your kids' wear brand, we should talk. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss manufacturing your next clothing order with Shanghai Fumao. Let's build a successful and sustainable collection together.