The concept of Minimum Order Quantity (MOQ) is one of the most critical and variable factors when sourcing production for a kids' clothing brand. It represents the smallest number of units a factory is willing to produce for a single style, color, or total order. Understanding MOQs is not just about finding the lowest number, but about comprehending the trade-offs between cost, flexibility, and production feasibility. As a manufacturer, I can tell you that there is no universal answer, but rather a spectrum dictated by factory specialization, material complexity, and your brand's stage of growth.

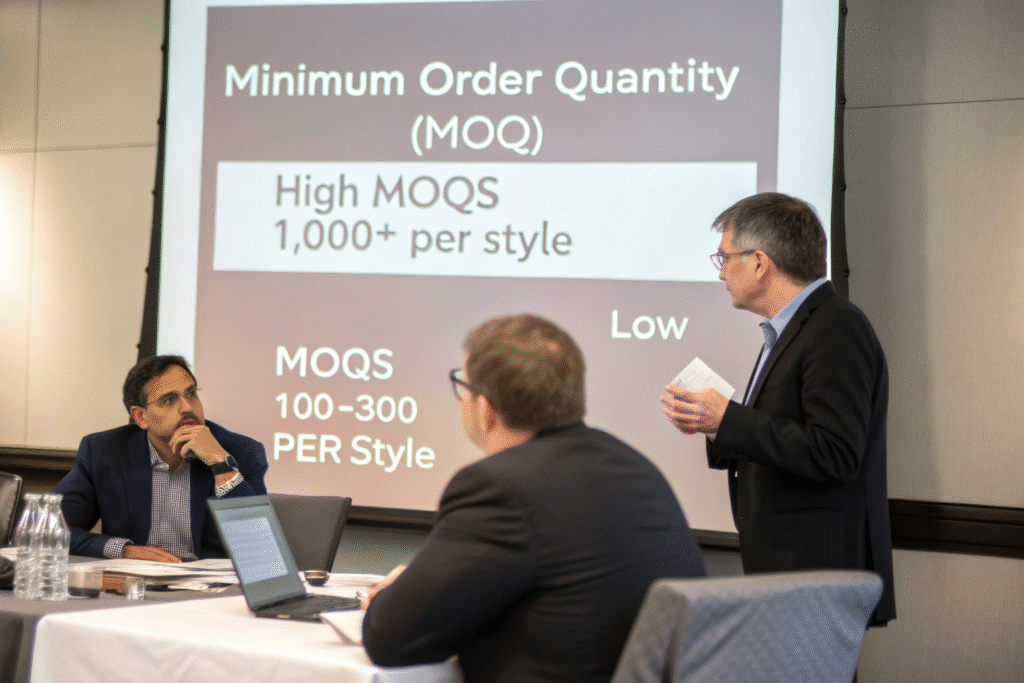

The minimum order quantity for kids clothing manufacturers typically ranges from 100 to 3,000 pieces per style/color, but can be as low as 50-100 pieces for small-batch specialists or exceed 5,000 for large-scale, commodity-focused factories. The final MOQ is determined by fabric type (common vs. custom), garment complexity, and the factory's business model (small-batch agile vs. high-volume efficiency).

Navigating MOQs successfully is key to managing cash flow, testing the market, and scaling responsibly. Let's demystify what drives these numbers and how to find the right fit for your brand.

What Factors Dictate a Manufacturer's MOQ?

A factory's MOQ is not an arbitrary number; it's a financial calculation of the minimum volume needed to make a production run economically viable for them. Setting up a production line involves fixed costs (pattern making, grading, marker making, machine setup) that are amortized over the number of units produced. The MOQ ensures these costs are covered.

Key factors include: Fabric Sourcing Minimums (mills often have high minimums per color/print), Cutting Efficiency (fabric is laid in many layers; cutting too few pieces is wasteful), Labor and Machine Setup Time (complex styles require more setup), and the factory's Operational Overhead. A factory specializing in small batches has optimized its processes for low MOQs, often at a higher cost per unit.

How Does Fabric Choice Dramatically Impact MOQ?

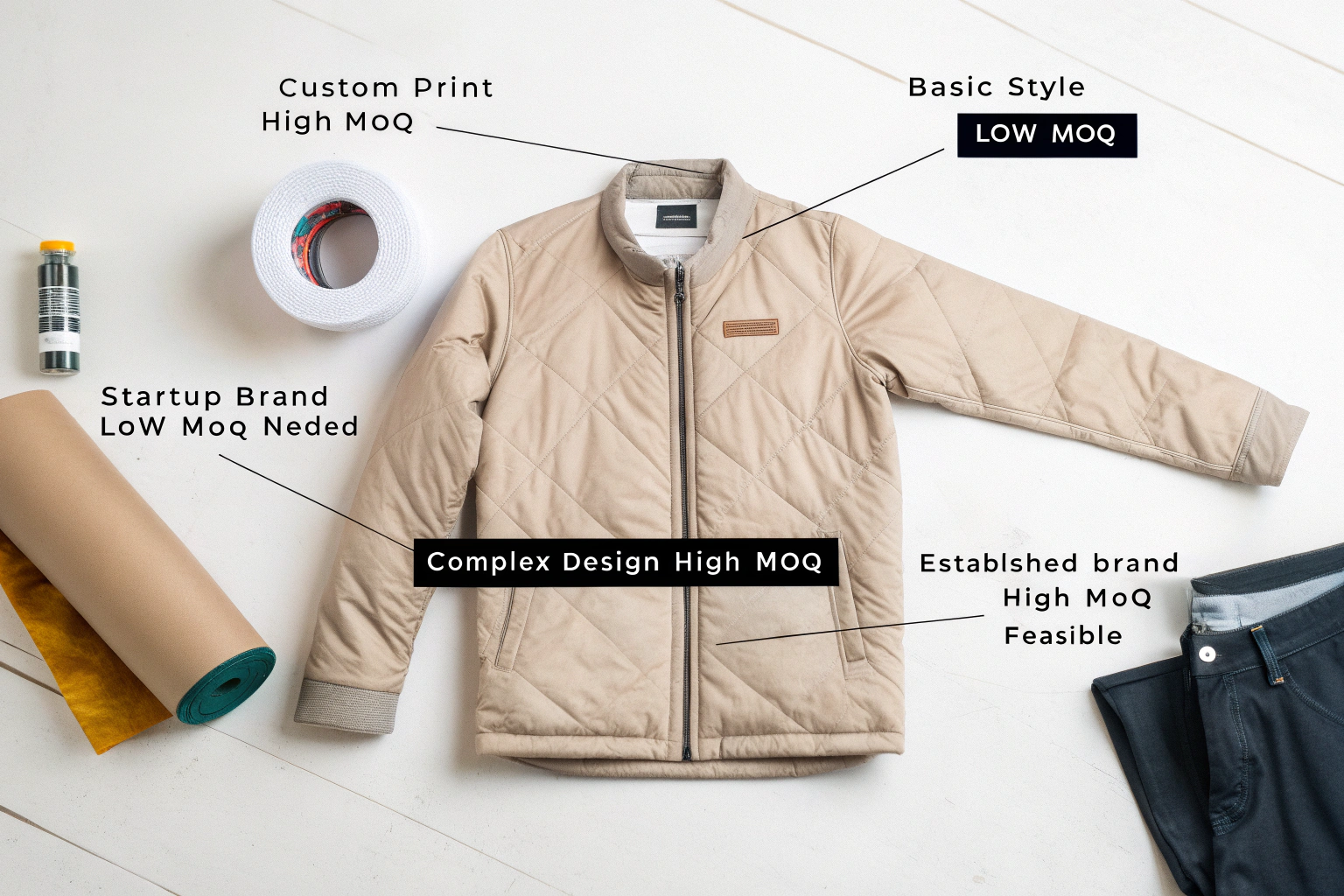

The fabric is often the biggest MOQ driver. There are two main scenarios:

- "In-Stock" or Stock Fabrics: The factory already has the fabric in its warehouse from a previous bulk order. They can sell it to you by the meter/yard with a low minimum. This allows for very low production MOQs (e.g., 100 pieces).

- Custom Developed Fabrics: You want a specific color, print, or composition that the factory must source or develop. The fabric mill will have its own MOQ (often 1,000+ yards/kg). You must meet the mill's MOQ before the factory can even cut your garment. This forces your garment MOQ to be high.

Pro Tip: Work with manufacturers who have a diverse in-stock fabric library for prototyping and initial low-volume runs.

Why Does Garment Complexity Influence MOQ?

A simple t-shirt requires one main fabric, few pattern pieces, and simple stitching. A winter coat with a waterproof membrane, insulation, lining, multiple zippers, and intricate detailing is a different story.

- Simple Styles (Tees, Leggings, Basic Dresses): Can often be produced at lower MOQs (300-500 pieces).

- Complex Styles (Jackets, Technical Outerwear, Multi-piece Sets): Typically have higher MOQs (1,000-3,000+ pieces) due to more components, longer setup, and skilled labor required.

The factory must justify the time spent engineering and setting up for a complex style, which only makes sense with higher volume.

What Are the Different Types of MOQs to Understand?

When discussing MOQ with a factory, you must clarify what the minimum applies to. Misunderstanding here can lead to unexpected costs. There are typically three layers of MOQs in a production order.

These are: Per Style MOQ, Per Colorway MOQ (within a style), and Total Order MOQ (the minimum total spend or piece count across all styles in your order). A factory might say "MOQ 300 pieces per style, with a 500-piece total order minimum." This means you could order 2 styles at 250 pieces each to meet the total.

What is the Difference Between "Per Style" and "Per Color" MOQ?

This is a crucial distinction. Let's say a factory has an MOQ of 500 pieces per style, per color.

- Scenario A: You want 500 black t-shirts. You meet the MOQ.

- Scenario B: You want the same t-shirt in black, white, and pink (3 colors). If you want 167 black, 167 white, and 166 pink, you do NOT meet the MOQ, because each color is under 500. You would need 500 black and 500 white and 500 pink (1,500 total pieces).

Many small-batch factories offer "Per Style" MOQs that allow you to split the quantity across colors (e.g., MOQ 300 pieces for Style X, which can be 150 in Blue, 100 in Pink, 50 in Yellow). This is far more flexible for startups.

How Do "Total Order" MOQs Work for New Brands?

A Total Order MOQ is the factory's bottom line for accepting an order. For a new brand with limited capital, finding a factory with a low total order MOQ (e.g., 300-500 total pieces, regardless of how many styles) is ideal. It allows you to produce a small, curated first collection. Some factories offer this by allowing you to use the same in-stock fabric across multiple styles, so their fabric MOQ is met by the aggregate yardage of your entire order. Always ask: "What is the smallest total order you can accept?"

How Can Startups Navigate and Negotiate MOQs?

As a new brand, you cannot typically meet the MOQs of large-scale manufacturers. Your strategy should focus on finding partners who cater to the startup and small-batch market. Transparency about your goals and growth plans can sometimes lead to flexibility.

Tactics include: Seeking out small-batch or "starter program" manufacturers, using stock fabrics exclusively for your first order, designing a capsule collection with fabric sharing in mind, and exploring pre-order campaigns to validate demand and fund production before committing to the MOQ.

What Are "Low MOQ" or "No MOQ" Manufacturers?

A growing segment of factories, often in China and Pakistan, now explicitly market "Low MOQ" services (as low as 50-100 pieces per style). These are not myths, but they come with important caveats:

- Higher Unit Cost: The factory's fixed costs are spread over fewer units.

- Limited Customization: You may be restricted to their in-stock fabric and trim selections.

- Simpler Styles: They are set up for efficiency on basics.

These manufacturers are perfect for MVP (Minimum Viable Product) launches, test runs, and very small brands. They are a gateway to production, not usually a long-term solution for complex designs.

Can You Negotiate MOQs with a Manufacturer?

Yes, to a degree. Negotiation is more successful if you:

- Show Growth Potential: Present a business plan showing you intend to scale, making you a valuable long-term partner.

- Offer Repeat Business: Commit to a schedule of re-orders if the first sell-through is successful.

- Be Flexible: Agree to use their recommended, in-stock fabrics for the first order to reduce their sourcing risk.

- Combine with Other Small Brands: Some factories offer "shared production" where multiple brands combine orders to meet a fabric MOQ, though this is complex to coordinate.

The relationship is key. A manufacturer who believes in your vision is more likely to work with you.

What Are the Strategic Implications of Choosing an MOQ Level?

Your choice of MOQ level is a strategic business decision that impacts your cash flow, inventory risk, and ability to innovate. There is a direct trade-off between cost efficiency and flexibility.

High MOQs (1,000+ per style) mean a lower cost per unit but high upfront capital, significant inventory holding risk, and less agility to respond to trends. Low MOQs (100-300 per style) mean a higher cost per unit but low cash outlay, minimal deadstock risk, and the ability to test and iterate designs rapidly.

How to Use a "Phased" MOQ Strategy for Scaling?

A smart approach is to start with a low-MOQ manufacturer for your Launch Collection. Use this to test the market, gather customer feedback, and generate revenue. Once you have validated best-sellers and built capital, you can "grade up" to a mid-sized manufacturer for your Growth Collection, placing larger re-orders on proven styles and introducing a few new ones at a higher MOQ. Finally, for core basics that sell consistently, you can move to a high-volume manufacturer for maximum cost efficiency. This phased strategy aligns production with your business maturity.

What is the Link Between MOQ, Inventory, and Sustainability?

Low-MOQ production is inherently more sustainable from an inventory waste perspective. Producing small, demand-informed batches prevents overproduction and the subsequent need to landfill or incinerate unsold stock. While the carbon footprint per unit might be slightly higher due to less optimized production runs, the overall environmental impact is often lower when full lifecycle (including waste) is considered. For a values-driven brand, this can be a compelling reason to partner with a small-batch manufacturer despite the higher unit cost.

Conclusion

The Minimum Order Quantity is a fundamental gateway in apparel manufacturing, especially for kids' wear where testing and iteration are crucial. There is no "best" MOQ, only the right MOQ for your brand's current stage, financial reality, and strategic goals. By understanding the drivers (fabric, complexity), clarifying the terms (per style vs. per color), and strategically targeting manufacturers whose business model aligns with your needs (small-batch vs. large-scale), you can turn MOQ from a barrier into a tool for smart, scalable growth.

At Fumao Clothing, we specialize in serving emerging and growing brands with flexible, low-MOQ options (often starting at 300 pieces per style, with negotiable total order minimums). We maintain an in-stock fabric library to facilitate this and guide our partners through a phased scaling strategy. If you are looking for a manufacturing partner that grows with you, let's discuss how we can make your first—or next—collection a reality without overextending your resources. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to explore your MOQ possibilities.