As a children's clothing manufacturer with decades of experience serving American and European brands, I understand that lead time is one of your most critical concerns. Getting your collections to market at the right moment makes the difference between capitalizing on trends and missing your selling season entirely. The answer to this question requires looking at multiple factors that influence the production timeline.

The typical lead time for manufacturing kids clothing in China ranges from 45 to 90 days, with 60 days being the average for standard orders. However, this timeline varies significantly based on order complexity, fabric sourcing, seasonality, and factory capacity. Understanding these variables helps you plan realistically and avoid costly delays that impact your business.

Proper planning and clear communication with your manufacturer can optimize this timeline, but understanding the components that build up to these timeframes is essential for setting accurate expectations with your retail partners and customers.

What factors determine your specific production timeline?

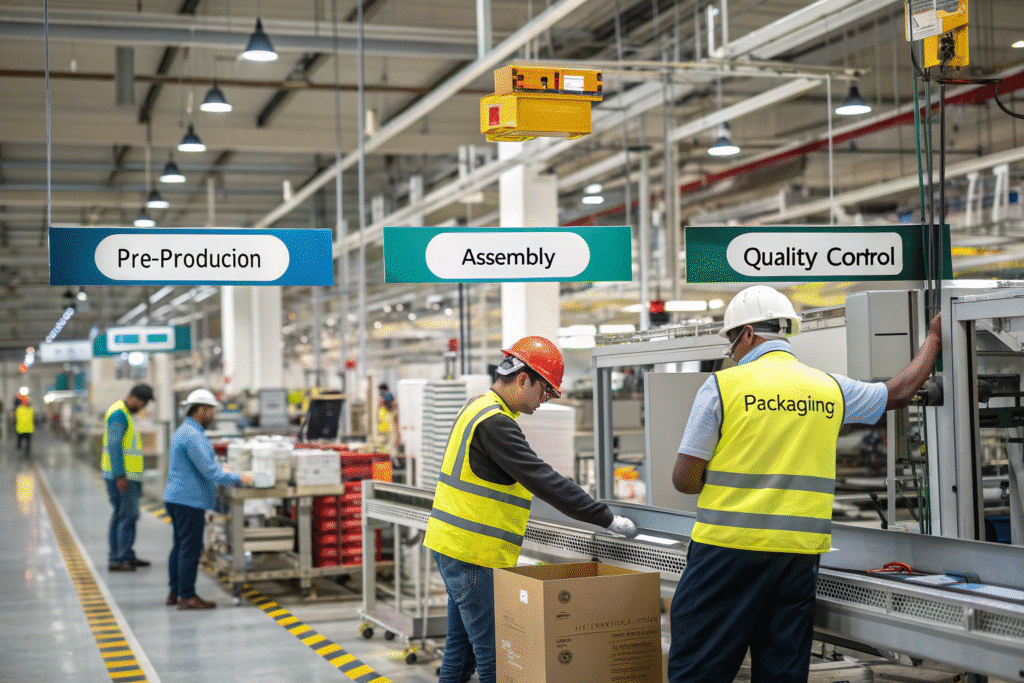

Your manufacturing lead time isn't arbitrary—it's the sum of multiple interconnected processes, each with its own timeline. Understanding these components helps you identify where efficiencies can be gained and where potential bottlenecks might occur.

The production clock starts ticking only after all preliminary steps are completed. These pre-production phases often consume more time than brands anticipate, particularly for first-time collaborations or complex designs. A realistic timeline accounts for each of these stages while building in buffer time for unexpected delays.

How does design complexity impact lead times?

Design complexity significantly influences your manufacturing timeline through several key factors. intricate designs with multiple components like special trims, custom prints, or elaborate embroidery require additional sourcing and production steps, potentially adding 1-3 weeks to your timeline. Technical designs needing complex pattern-making and sample approvals extend the development phase before production even begins. New product categories that a factory hasn't previously manufactured for you require more extensive setup and process development. Additionally, garments requiring special construction techniques like waterproof sealing or specialized stitching often need extra time for worker training and quality standard establishment. Understanding these variables helps you make informed trade-offs between design ambition and timeline requirements.

What role does fabric sourcing play in your schedule?

Fabric sourcing represents one of the most variable factors in your production timeline, with implications many brands underestimate. Ready stock fabrics available in the manufacturer's warehouse can save 2-3 weeks compared to mill orders. Domestic Chinese fabric production typically takes 2-4 weeks for weaving, dyeing, and finishing. Imported fabrics from other countries like Korea or Japan add 1-2 weeks for shipping and customs clearance. Custom-developed fabrics requiring special yarns, weaves, or treatments can extend sourcing to 6-8 weeks. Additionally, fabrics needing special certifications like OEKO-TEX or GOTS may require additional testing and documentation time. Your manufacturer should provide transparent updates about fabric status throughout this process.

How can you optimize your production schedule?

Strategic planning and informed decision-making can significantly compress your manufacturing timeline without compromising quality. Brands that understand the manufacturing process can shave weeks off their lead times through smart choices and proactive management.

Optimization begins long before production starts, with decisions made during the design and development phases having profound impacts on your eventual timeline. Working with an experienced manufacturer who can guide these decisions is invaluable for brands operating on tight schedules.

| Timeline Factor | Standard Duration | Optimization Strategies |

|---|---|---|

| Fabric Sourcing | 2-4 weeks | Use mill stock fabrics, pre-position materials |

| Sample Approval | 1-3 weeks | Provide detailed tech packs, use digital approvals |

| Production Planning | 1-2 weeks | Plan seasons ahead, confirm capacity early |

| Mass Production | 3-5 weeks | Streamline designs, avoid mid-stream changes |

| Quality Control | 3-7 days | Implement inline checks, use local inspectors |

| Shipping | 2-4 weeks | Book freight early, consider air for urgent orders |

What planning strategies reduce manufacturing delays?

Proactive planning strategies can significantly reduce manufacturing delays and create more predictable timelines. Developing your collections 6-9 months before needed delivery dates provides adequate time for sampling, revisions, and production without rush fees. Creating comprehensive tech packs with detailed specifications, approved fabric swatches, and clear graphics minimizes back-and-forth during sampling. Establishing long-term partnerships with manufacturers who understand your quality standards and design aesthetic streamlines communication and reduces learning curves. Planning production during factory low seasons (typically January-February and June-July) often results in faster turnaround times and potentially better pricing. Additionally, using digital prototyping where possible can reduce physical sampling iterations by 50% or more.

How does order quantity affect production speed?

Order quantity creates a complex relationship with production speed that isn't always linear. Small orders (under 500 pieces per style) typically move faster through production but may be deprioritized for larger accounts. Medium orders (500-2,000 pieces) represent the sweet spot where efficiency gains are realized without overwhelming capacity. Large orders (over 2,000 pieces) may require production scheduling across multiple lines or facilities, potentially extending timelines. Additionally, orders with multiple colorways and sizes within a style require more setup time but benefit from economies of scale once running. The most efficient approach often involves grouping smaller quantities into cohesive collections that can be produced together, optimizing factory scheduling while maintaining variety in your line.

What are the hidden time costs in manufacturing?

Beyond the obvious production phases, several less visible factors can significantly impact your timeline. Awareness of these potential delays helps you build more accurate schedules and maintain realistic expectations throughout the process.

The manufacturing process involves numerous dependencies and sequential steps where delays in one area create ripple effects throughout the timeline. Understanding these interconnected processes helps you identify critical path items that require particular attention.

How do certification requirements extend timelines?

Certification requirements, while valuable for market access and consumer trust, add specific time considerations to your production schedule. Testing for safety standards like CPSIA compliance typically requires 1-2 weeks for laboratory analysis and documentation. Organic or sustainability certifications like GOTS may involve additional verification steps throughout the production process. Factory social compliance audits, if required by your purchasing policy, need scheduling and implementation time. Import documentation preparation for different markets requires careful attention to avoid customs delays. Additionally, any special packaging or labeling requirements necessitate additional proofing and approval steps. While these processes ensure quality and compliance, they must be accounted for in your overall timeline planning.

What logistical factors impact final delivery dates?

Logistical considerations represent the final variable in your manufacturing timeline, with several factors influencing when goods actually reach your warehouse. Shipping method selection creates the most significant variance—air freight takes 3-7 days but costs substantially more, while sea freight takes 3-5 weeks but offers better economics. Customs clearance duration varies by country and season, with holiday periods often experiencing extended processing times. Documentation accuracy critically impacts clearance—any errors can cause week-long delays. Transportation from Chinese ports to your destination warehouse adds additional time, particularly for inland locations. Additionally, incoterms determine responsibility for various logistics steps, with DDP arrangements often providing more predictable timelines as the manufacturer controls the entire process until delivery to your warehouse.

How does seasonality affect Chinese manufacturing timelines?

Production capacity in China follows predictable seasonal patterns that significantly impact lead times. Understanding these cycles helps you plan your development and production calendar to avoid peak congestion periods.

The manufacturing calendar revolves around Chinese holidays, international retail seasons, and raw material production cycles. Brands that align their production schedules with these patterns secure better factory attention, more competitive pricing, and more reliable delivery dates.

What are the peak production seasons in China?

China's manufacturing calendar features distinct peak seasons that create capacity constraints and extended lead times. The busiest period runs from March through May as factories fulfill orders for back-to-school and holiday collections. A second significant peak occurs from August to October as production focuses on spring and summer collections for the following year. Chinese New Year (typically January or February) creates a massive pre-holiday rush as factories complete orders before the 2-4 week shutdown, followed by a slow ramp-up period as workers gradually return. Additionally, European and American holiday seasons create indirect pressure as brands rush to ensure inventory for Black Friday and Christmas selling periods. Production scheduled during shoulder seasons (June-July and November-December) typically experiences fewer delays and may receive more factory attention.

How should you plan around Chinese holidays?

Strategic planning around major Chinese holidays is essential for maintaining predictable production timelines. Chinese New Year (typically 2-4 weeks in January/February) requires placing fabric orders at least 6 weeks before closure and completing production 3-4 weeks before the holiday begins. National Day Golden Week (one week in early October) necessitates similar advanced planning, though the impact is generally less severe than Chinese New Year. The Qing Ming Festival (April), Dragon Boat Festival (June), and Mid-Autumn Festival (September) each cause 3-5 day closures that can disrupt production flow if they occur during critical phases. Manufacturers typically publish their holiday schedules 2-3 months in advance, allowing savvy brands to adjust their timelines accordingly. Building buffer time around these periods prevents last-minute surprises and ensures your production maintains its schedule.

Conclusion

Understanding lead times for manufacturing kids clothing in China requires looking beyond simple production days to encompass the complete journey from design conception to delivery at your warehouse. The typical 45-90 day timeline represents a complex interplay of design complexity, fabric availability, production capacity, certification requirements, logistics, and seasonal factors. Brands that develop realistic timelines based on these variables, maintain clear communication with their manufacturers, and plan their production calendars strategically position themselves for timely deliveries that align with their selling seasons.

At Fumao Clothing, we've helped numerous children's wear brands navigate these timelines through transparent scheduling, proactive communication, and efficient production systems. Our experience with American and European brands means we understand the importance of delivering quality collections on time, every time. If you're looking for a manufacturing partner who provides realistic timelines and reliable execution, contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can meet your production schedule requirements while maintaining the quality standards your brand deserves.