Choosing the right manufacturing partner is one of the most critical decisions your clothing brand will make. The manufacturer you select impacts everything from product quality and production timelines to your brand reputation and profitability. Asking the right questions during the selection process can mean the difference between a successful partnership and a costly mistake that sets your business back months or even years.

The top questions to ask a potential clothing manufacturer should cover their production capabilities and capacity, quality control processes, communication protocols, pricing structure and transparency, ethical compliance, and experience with your specific product category and market. These questions help you assess not just their technical capabilities but also whether they're the right cultural and strategic fit for your brand's needs.

A thorough vetting process goes beyond checking boxes on a capability list. It involves understanding how the manufacturer approaches problem-solving, manages challenges, and aligns with your brand values and business objectives. Let's explore the crucial questions that will help you identify the ideal manufacturing partner for your clothing line.

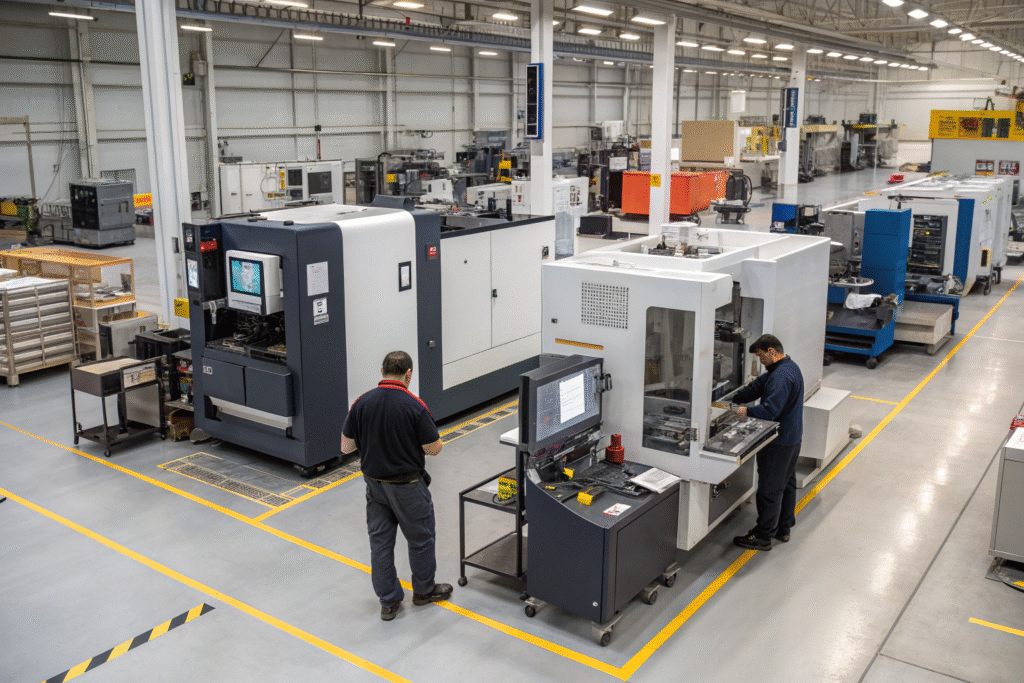

What production capabilities and capacity do they offer?

Understanding a manufacturer's technical capabilities and production capacity ensures they can handle your specific requirements both now and as your business grows. This assessment goes beyond simple yes/no questions to explore how they approach production challenges and scale operations.

Questions about production capabilities should cover their equipment types and condition, workforce size and skill levels, production capacity across different product categories, lead time requirements, and scalability options for business growth. These factors determine whether they can consistently deliver your required quality and quantities.

What specific equipment and techniques can they handle?

Ask about their equipment for different construction methods—do they have specialized machines for knit versus woven fabrics, embroidery equipment, printing capabilities, or technical sewing machines for specific details? Inquire about their experience with different fabric types and whether they have relationships with fabric mills for sourcing. For children's wear specifically, ask about their experience with safety features like breakaway drawstrings, non-toxic dyes, and flame-resistant sleepwear construction. Their answers will reveal their technical sophistication and whether they can execute your design details properly.

How do they manage production capacity and lead times?

Request specific information about their current production capacity—how many units they can produce monthly across different garment types—and what percentage of their capacity is currently utilized. Ask for typical production lead times from confirmed order to shipment for both small and large orders. Importantly, ask how they handle rush orders and production delays caused by material shortages or other disruptions. Their answers will help you assess whether they can meet your timeline requirements and how they manage the inevitable challenges that arise in manufacturing.

How do they ensure and maintain quality control?

Quality control processes separate exceptional manufacturers from mediocre ones. Understanding their approach to quality assurance helps you predict consistency across production runs and identify potential issues before they reach your customers.

Questions about quality control should cover their inspection procedures at different production stages, measurement and tolerance standards, defect tracking systems, quality documentation provided, and how they handle quality issues when they occur. A transparent quality process builds confidence in their reliability.

What specific quality checks do they implement?

Ask about their quality control process at each production stage: fabric inspection before cutting, in-process checks during sewing, and final random inspection before shipping. Request details about their AQL (Acceptable Quality Level) standards and how they determine inspection sample sizes. For children's products specifically, inquire about their testing procedures for safety standards like lead content, phthalates, and flammability requirements. Their specificity in answering these questions indicates their commitment to systematic quality management rather than casual inspection.

How do they document and address quality issues?

Ask how they document quality issues throughout production and what reporting they provide to clients. Request examples of their quality control reports and defect classification system. Importantly, ask how they handle products that fail quality inspection—do they repair, replace, or discount them? What is their process for addressing consistent quality problems with particular styles or operators? Their approach to problem-solving reveals much about their operational maturity and commitment to continuous improvement.

What communication and project management systems do they use?

Effective communication can make or break a manufacturing partnership. Understanding how you'll interact throughout the production process helps prevent misunderstandings and ensures smooth collaboration despite language and cultural differences.

Questions about communication should cover primary contact points, response time expectations, update frequency and format, language capabilities, and systems for tracking order progress. Clear communication protocols prevent frustrations and keep production on track.

Who will be your main points of contact?

Identify who will manage your account day-to-day versus who handles technical questions, quality issues, and shipping logistics. Ask about their client communication structure—do you work with a dedicated account manager who understands your specific needs, or will you interact with different departments separately? For international partnerships, inquire about language capabilities and time zone availability for meetings. Clear communication channels prevent the frustration of not knowing who to contact for specific issues.

How do they provide production updates?

Ask about their system for providing regular production updates—whether through scheduled reports, an online portal, or proactive communication about milestones and potential delays. Request examples of how they typically communicate progress and handle problems when they arise. Do they provide photos at key production stages? How do they communicate about material delays or other disruptions? Their transparency in keeping clients informed demonstrates professionalism and respect for your business planning needs.

What is their complete pricing structure?

Understanding the full cost picture prevents unexpected expenses and helps you accurately calculate your profit margins. Transparent pricing demonstrates a manufacturer's integrity and helps build trust in the partnership.

Questions about pricing should cover all cost components, payment terms and schedule, minimum order quantities, cost drivers for different design elements, and policies for price changes over time. Comprehensive understanding of costs helps you make informed decisions about your product pricing strategy.

What costs are included in their quotes?

Request a detailed breakdown of all cost components: fabric, trims, labor, overhead, profit margin, and any additional fees for testing, documentation, or shipping. Ask specifically about hidden costs like sample charges, mold fees for custom buttons or zippers, or minimum surcharges for small orders. For international manufacturers, clarify what Incoterms they're quoting (FOB, EXW, CIF, etc.) and what costs you'll be responsible for beyond their quoted price. Detailed cost understanding prevents budget surprises later.

How do they handle minimum orders and payment terms?

Ask about their minimum order quantities by style, color, and total order, and whether these can be combined across different products. Inquire about their standard payment terms—deposit percentage, progress payments, and balance payment timing. Ask how they handle price changes for reorders, especially if material costs fluctuate. Their flexibility and transparency around minimums and payment terms can significantly impact your cash flow and inventory strategy, especially for new brands.

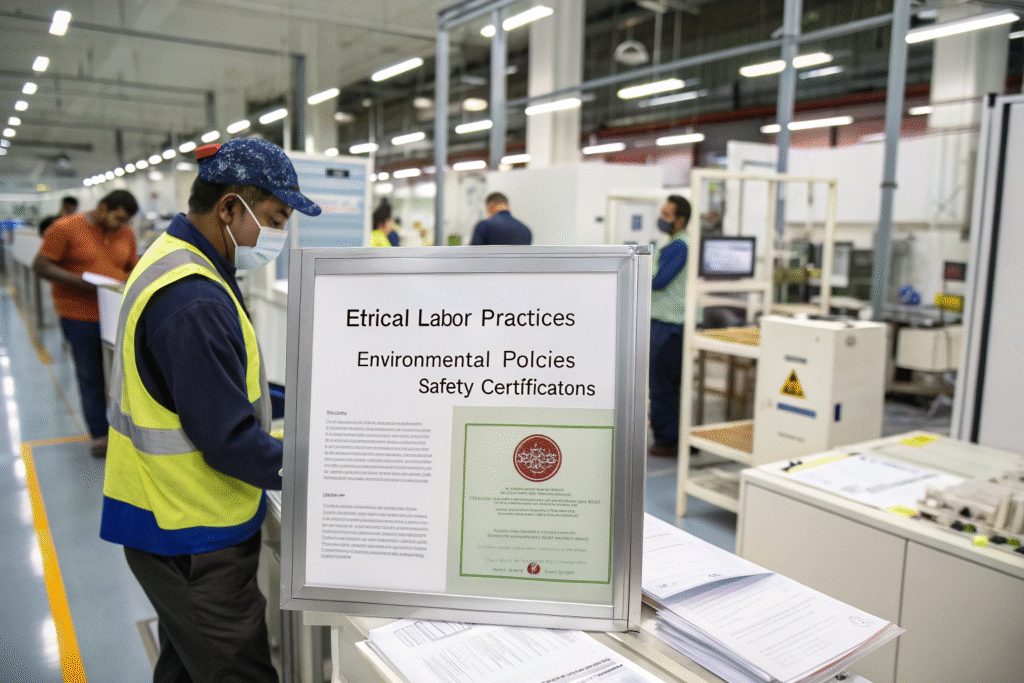

What are their ethical and compliance standards?

A manufacturer's ethical practices and compliance documentation affect both your brand reputation and your ability to meet regulatory requirements, particularly important for children's products with strict safety standards.

Questions about ethics and compliance should cover their labor practices, environmental policies, safety certifications, documentation capabilities, and audit willingness. Responsible manufacturing practices protect your brand from reputation damage and supply chain disruptions.

What certifications and audits do they maintain?

Ask about specific certifications like WRAP, BSCI, or SA8000 for social compliance, GOTS for organic materials, or OEKO-TEX for chemical safety. Request copies of their audit reports and verify they're from reputable third-party organizations, not self-certified. For children's wear manufacturers specifically, ask about their experience with CPSIA compliance documentation and testing requirements. Their certification depth indicates their commitment to responsible manufacturing practices.

How do they ensure ethical labor practices?

Ask about their worker recruitment practices, working hours, wage structure, and benefits. Inquire about their policy on forced labor and child labor verification. Request to speak with current clients about their experiences and, if possible, visit the facility yourself or hire a third-party inspector. Their willingness to be transparent about working conditions and their philosophy toward worker treatment reveals their ethical commitment beyond mere compliance.

Can they provide relevant references and samples?

Evidence of past performance offers the most reliable indicator of future performance. Checking references and evaluating samples provides concrete proof of their capabilities and reliability.

Questions about references and samples should cover their experience with similar brands, ability to provide relevant client contacts, sample cost and timing, and willingness to create custom samples based on your specifications. Hands-on evaluation provides the most accurate assessment of their capabilities.

What can references tell you about their reliability?

Ask for references from brands with similar production needs to yours—similar volume, product type, or market segment. When speaking with references, ask specific questions about communication reliability, quality consistency, problem-solving approach, and whether they'd use the manufacturer again for new projects. Ask about any challenges they faced and how the manufacturer responded. Reference conversations often reveal nuances that don't emerge during formal presentations.

How do their samples demonstrate capabilities?

Request samples similar to your intended products, not just their best showcase pieces. Evaluate the sample quality critically—check stitching consistency, fabric quality, pattern matching, and attention to detail. Ask about their sample process—how many revisions they typically require, costs involved, and timeline from design to finished sample. Their sample quality and process often predict how they'll handle your full production run, making this one of the most important evaluation steps.

Conclusion

Asking comprehensive questions during the manufacturer selection process protects your business from costly mistakes and establishes a foundation for a successful long-term partnership. The most important considerations extend beyond technical capabilities to include communication style, ethical alignment, problem-solving approach, and cultural fit with your brand values.

Ready to find the right manufacturing partner for your clothing line? Our transparent processes and commitment to quality make us the ideal choice for brands seeking reliable production with clear communication. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to schedule a consultation and get detailed answers to all these important questions.