As a children's clothing manufacturer with decades of experience supplying major brands, I understand the critical importance of anticipating market trends. With winter 2025 approaching, industry stakeholders need to identify which pieces will drive sales and meet evolving consumer expectations. The question extends beyond aesthetics to encompass technical innovation, supply chain reliability, and compliance with international standards.

The essential kids' clothing items for Winter 2025 will integrate smart textile technologies, modular layering systems, and certified sustainable materials that meet both CPSC and EN 14682 safety standards while maintaining commercial viability. Critical SKUs will include thermally regulated outerwear, convertible multi-season pieces, and traceable eco-performance base layers designed for the discerning North American and European markets.

The upcoming season represents a significant evolution in children's apparel engineering. Let's examine the specific product categories that will dominate wholesale orders and retail performance.

What Technical Innovations Are Driving Winter Jacket Development for 2025?

The winter jacket category is undergoing substantial technological transformation. For the 2025 season, product development focuses on integrating advanced materials science with practical commercial applications that address both performance requirements and production scalability.

The dominant innovation involves micro-encapsulated phase-change materials (PCMs) integrated within insulation layers, providing autonomous thermal regulation without external power sources. Additionally, we're implementing bluesign® certified water-repellent finishes with enhanced durability against industrial laundering. These technical enhancements directly respond to brand requirements for differentiated products that justify premium wholesale pricing while maintaining feasible minimum order quantities and production timelines.

How Are Smart Textiles Revolutionizing Thermal Management?

Smart textiles now incorporate bio-mimetic principles through advanced knitting technologies that create variable porosity in response to body temperature. Our manufacturing facilities have adopted seamless knitting machinery that produces complex structural patterns enhancing thermal efficiency without adding weight. These technical knits utilize specialized yarns like recycled polyamide blends with ceramic particles for passive heat retention. This represents a significant advancement over previous generations of insulated children's outerwear.

What Engineering Solutions Address Sizing and Longevity Challenges?

We've developed proprietary adjustable panel systems using precision laser-cutting techniques and reinforced bar-tacking at stress points. These engineering solutions allow for up to three inches of vertical and horizontal adjustment throughout the garment's core panels. The implementation of YKK® VISLON® waterproof zippers with oversized pulls addresses dexterity challenges while ensuring durability through rigorous quality control protocols. These features directly impact brand satisfaction by reducing returns and enhancing perceived value.

How Should Base Layer Specifications Be Optimized for Performance?

The base layer serves as the foundational element in the winter layering system, requiring precise material selection and construction techniques to ensure optimal moisture management and thermal efficiency. Proper specification is critical for brand differentiation and product performance claims.

Premium base layers for 2025 will utilize advanced natural and synthetic blends optimized for specific activity levels. Merino wool hybrids (typically 60-70% merino with recycled polypropylene) provide optimal moisture-wicking for high-exertion scenarios, while Tencel™ Modal blends with silver ion technology offer superior antimicrobial properties for extended wear. The strategic selection of yarn composition and knit structure directly impacts the garment's performance characteristics and compliance with international textile testing standards.

What Material Properties Determine Base Layer Efficacy?

The critical performance metrics include moisture vapor transmission rate (MVTR), drying time, and thermal conductivity. Merino wool's natural keratin structure creates microscopic air pockets that provide insulation even when damp, while Tencel's lyocell fibers offer 50% greater moisture absorption than cotton. Our production team conducts standardized laboratory testing to validate these properties, ensuring consistent batch-to-batch performance that meets our clients' technical specifications.

What Certification Standards Should Brands Prioritize?

Brands should mandate Oeko-Tex Standard 100 Class I certification for all base layers, which restricts over 100 harmful substances specifically for children's wear. Additionally, GOTS (Global Organic Textile Standard) certification provides assurance of organic fiber content and environmentally responsible processing. These certifications are no longer premium options but industry expectations for mid-to-high-tier brands, particularly in European markets where regulatory scrutiny is increasing.

What Design Features Define Contemporary Winter Overalls?

Modern winter overalls have evolved into sophisticated technical garments incorporating ergonomic design principles and production efficiencies that benefit both end-users and brand operations. The category now demands specialized pattern-making and strategic material placement.

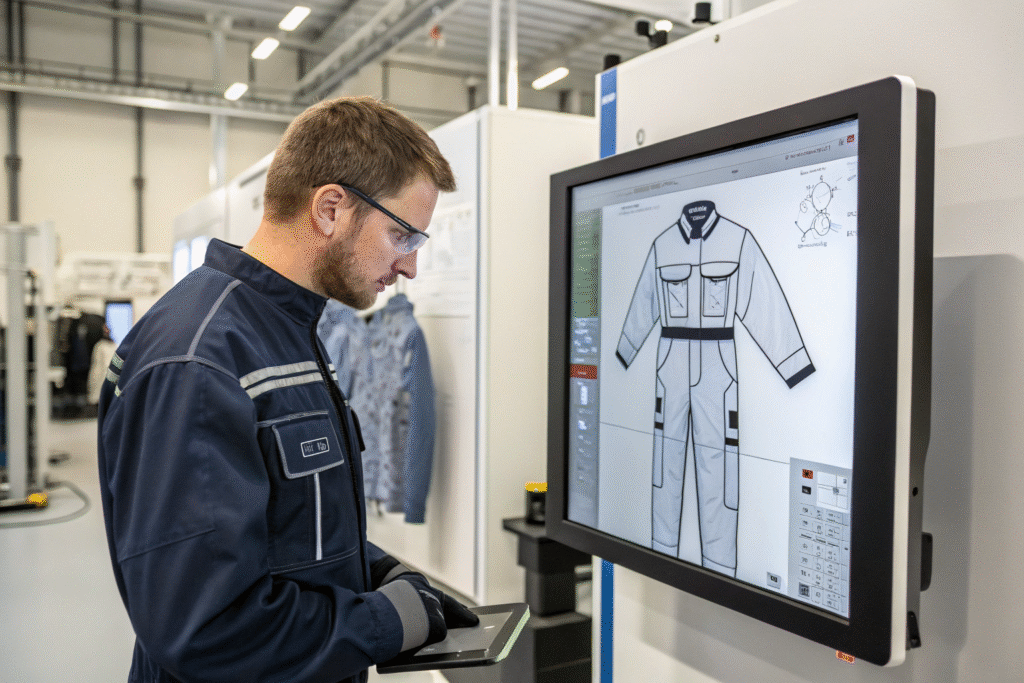

Key differentiators include fully welded seam construction eliminating needle perforations that compromise waterproof integrity, magnetic closure systems with reinforced anchor points, and integrated safety features like certified reflective elements meeting EN 13356 visibility standards. Our manufacturing approach utilizes 3D virtual prototyping to optimize pattern efficiency and minimize material waste, resulting in improved production line efficiency while maintaining design integrity across extended size ranges.

How Does Ergonomic Pattern-Making Enhance Functionality?

We employ biomechanical movement analysis to inform our pattern development, creating articulated knee and seat areas that accommodate a child's range of motion without excess material bunching. This approach utilizes gusseted inseams and raglan-style shoulder construction to eliminate restriction points. The resulting patterns require specialized cutting equipment but significantly enhance the wearer's comfort and mobility, translating to stronger product reviews and reduced exchange rates for our brand partners.

What Production Considerations Impact Overall Design?

Design decisions must account for factory efficiency through standardized component modules and rationalized construction sequences. We've developed proprietary attachment methods for features like removable liners and adjustable straps that minimize specialized operator training while maintaining quality consistency across our five production lines. This systematic approach to design-for-manufacturing ensures reliable lead time adherence and cost predictability throughout production cycles.

Is Sustainable Material Sourcing Becoming Standard Industry Practice?

Sustainable material utilization has transitioned from marketing differentiation to fundamental operational requirement within the children's wear sector. This shift reflects evolving regulatory frameworks, brand risk management strategies, and concrete supply chain advantages.

Sustainable material sourcing is now an established industry baseline, driven by comprehensive ESG reporting requirements and tangible supply chain benefits including improved traceability and reduced compliance risks. Our procurement strategy prioritizes GRS (Global Recycled Standard) certified materials and closed-loop production systems that minimize resource input. This approach not only meets brand sustainability mandates but also enhances supply chain transparency and mitigates against raw material price volatility.

Which Sustainable Materials Offer Commercial Viability?

Post-consumer recycled polyester (rPET) and regenerated nylon now demonstrate price parity with virgin materials while offering identical performance characteristics. For natural fibers, BCI (Better Cotton Initiative) and recycled wool blends provide scalable solutions without premium pricing. Our material library includes over 50 certified sustainable fabrics with validated performance data and established supply chains, enabling clients to meet sustainability targets without compromising on cost or delivery schedules.

How Does Sustainability Impact Supply Chain Management?

Implementing certified sustainable materials actually streamlines supply chain management through improved traceability systems and standardized documentation. Our vertically integrated manufacturing model allows for granular tracking of material flow from raw material to finished garment, simplifying compliance with regulations like the Uyghur Forced Labor Prevention Act (UFLPA). This comprehensive approach reduces audit burdens and creates a competitive advantage in markets where regulatory compliance is increasingly complex.

Conclusion

Winter 2025 represents a convergence of technical innovation, sustainable practices, and sophisticated supply chain management within the children's apparel sector. The leading products will successfully integrate advanced material science with commercial manufacturing realities, delivering performance that meets both consumer expectations and brand operational requirements.

As an established manufacturer with extensive experience serving North American and European brands, Fumao Clothing has positioned our production capabilities to support clients in capitalizing on these trends. Our vertically integrated facility, comprising five specialized production lines, ensures consistent quality control and reliable delivery schedules. For brands seeking to develop technically advanced winter collections with competitive pricing and dependable supply chain support, we invite you to discuss your specific requirements. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to explore manufacturing partnerships for the upcoming season.