As a baby clothing manufacturer, I often hear from brand owners about a common pain point: parents complain their babies outgrow clothes too fast. This leads to repeated purchases and customer dissatisfaction. But what if clothes could grow with the child? This is not a fantasy. Innovative growth-adjustable baby clothes are transforming the children's wear market. They offer extended wear and significant value, addressing a key concern for both brands and end-consumers.

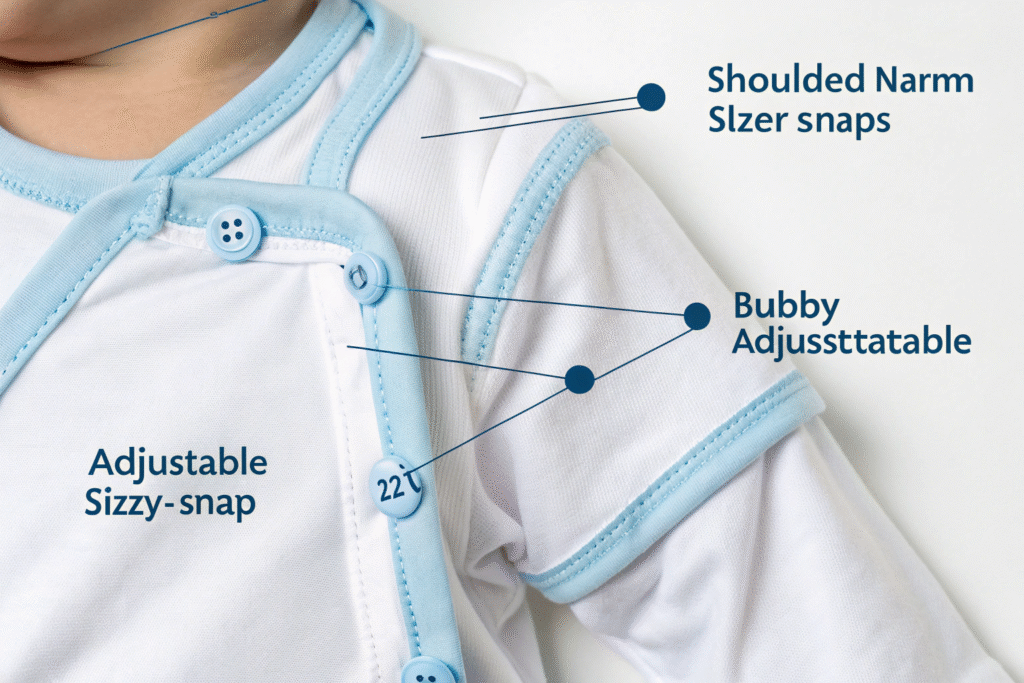

Growth-adjustable baby clothes are garments designed with features that allow the sizing to be extended, accommodating a child's rapid growth. These innovations include expandable cuffs, adjustable shoulder snaps, and extendable hems, which can add months to a garment's usable life. This approach directly tackles the problem of fast outgrowing, providing a practical solution that enhances product value and customer satisfaction for brands.

For business owners like you, understanding this product category is crucial. It represents a significant opportunity in the mid-to-high segment market. These designs meet the demand for premium quality and smart functionality. Let's explore the specific designs, benefits, and how they can become a profitable part of your collection.

What design features make baby clothes adjustable?

The core of growth-adjustable clothing lies in its design features. These are practical, often simple, modifications that add functionality without compromising on style or comfort. For brands, integrating these features requires a manufacturer with precise technical expertise and a deep understanding of garment construction.

Adjustable baby clothes incorporate specific design elements like extendable roll-up cuffs, multi-position shoulder snaps, and expandable waistbands. These features allow key areas of the garment to be let out or taken in, effectively creating multiple sizes in one. This solves the problem of garments becoming too small too quickly, offering parents a longer-lasting product and reducing the frequency of purchase.

How do adjustable cuffs and hems work?

Adjustable cuffs and hems are among the most common and effective features. Cuffs on sleeves and pants legs are often designed with extra fabric that can be unrolled as the child grows. We ensure a clean finish when unrolled, with no exposed seams. Similarly, hems can be sewn with a deeper allowance. This allows them to be let down, adding length to the body or legs of a garment. This simple design can extend a garment's life by 3 to 6 months. It is a key feature in our baby rompers and pajamas. We use high-quality, durable knitted fabrics that maintain their appearance even after adjustments.

What is the purpose of multi-position shoulder snaps?

Multi-position shoulder snaps are a hallmark of innovative baby bodysuits. Instead of a single set of snaps, we incorporate two or even three parallel rows. This allows the overlap of the crotch panel to be adjusted. A looser fit can be selected for a larger diaper or for growth. A tighter fit provides a snug, comfortable feel for a newborn. This system accommodates not just growth, but also variations in diaper size and baby's body shape. It's a small detail that offers significant practical value. We source our snaps from certified suppliers to ensure they withstand repeated use and washing, aligning with strict international safety standards.

Why should brands invest in adjustable baby clothing?

Investing in adjustable baby clothing is not just a product decision; it's a strategic business move. For brand owners and distributors, this category offers tangible benefits that directly impact the bottom line and brand reputation. It's a powerful response to a well-known market pain point.

Brands should invest in adjustable baby clothing because it significantly enhances customer loyalty and reduces product returns. By solving the "outgrow too fast" problem, you deliver exceptional value, which encourages repeat business and positive word-of-mouth. This directly addresses the business pain point of customer churn and builds a reputation for your brand as being thoughtful and innovative.

How does this design increase customer loyalty?

When a product lasts longer and solves a genuine problem, customers remember the brand that provided it. A parent who buys a bodysuit that lasts for 9 months instead of 3 is far more likely to return to your brand for their next purchase. This builds a strong emotional connection and trust. In a competitive market, this loyalty is a key differentiator. It turns one-time buyers into long-term advocates for your brand. By offering customizable logo options on these high-value items, you further strengthen that brand connection.

Can adjustable clothes improve profit margins?

Absolutely. While the initial cost per garment may be slightly higher due to more complex construction, the value proposition allows for a higher retail price point. Consumers are often willing to pay more for products that offer long-term savings and convenience. Furthermore, by reducing the frequency of purchase for the end-user, you are essentially consolidating the value of multiple garments into one. This enhances the perceived quality and justifies a premium position in the market, directly supporting a DDP mode of business where value is clear and upfront.

What quality controls are vital for adjustable garments?

The innovative features of growth-adjustable clothes are meaningless without rigorous quality control. The adjustable elements, like snaps and extended seams, are stress points that undergo repeated use. For a brand, a product failure here can damage reputation, making quality assurance non-negotiable.

Vital quality controls for adjustable garments include rigorous testing of adjustment mechanisms like snap fasteners and reinforced stitching. The fabric must also be tested for durability and colorfastness after repeated stretching and washing. This ensures the adjustable features remain functional and safe throughout the garment's extended lifespan, protecting your brand from returns and safety issues.

How do you test the durability of adjustable snaps?

We implement a multi-stage testing process for all snap fasteners. First, we conduct a pull-force test to ensure they cannot be detached easily, posing a choking hazard. Second, we simulate repeated use through a machine that opens and closes the snaps thousands of times. Finally, we subject the entire garment to multiple wash cycles and then re-test the snaps. This process guarantees that the snaps meet or exceed international safety standards such as those from the CPSC. We provide authentic certification for all our components to give our partners full confidence.

Why is fabric strength crucial for these designs?

Adjustable features often put extra stress on the fabric. For example, an expandable cuff is constantly stretched and released. We therefore select and test fabrics for high tear strength and abrasion resistance. We prioritize robust knitted fabrics that can maintain their integrity and shape over time. Our quality team conducts pre-production testing on all fabric rolls to ensure they meet our strict specifications for weight, stretch recovery, and colorfastness. This prevents issues like seam slippage or fabric thinning at the adjustment points, ensuring the garment looks and performs well for its entire life.

How to source reliable growth-adjustable clothing manufacturers?

Finding a factory that can reliably produce these technically advanced garments is the final, critical step. The wrong partner can lead to the very issues you fear: delayed shipments, quality failures, and miscommunication. Your sourcing strategy must focus on manufacturers with proven expertise and a transparent process.

To source reliable manufacturers for growth-adjustable clothing, focus on factories that specialize in technical baby wear and can provide verifiable certifications and a transparent quality control process. Look for partners with experience in your target market, such as North America and Europe, and who offer clear communication channels and project management, avoiding the pain point of inefficient sales reps.

What certifications should a manufacturer have?

A reliable manufacturer will hold certifications that validate their commitment to quality and safety. Key certifications to look for include OEKO-TEX® STANDARD 100, which ensures fabrics are free from harmful substances, and ISO 9001 for quality management systems. For the US market, compliance with CPSC regulations is essential. At our factory, we maintain these certifications and provide them openly to our partners. This transparency is our commitment to ensuring quality control and building trust, so you never have to worry about falsified documents.

Why is clear communication key in manufacturing?

Inefficient communication is a major pain point. To solve this, we assign a dedicated project manager, like our Business Director Elaine, to each client. This single point of contact manages everything from design to logistics, ensuring you are always updated. We provide regular production progress reports and are proactive in addressing any concerns. This streamlined communication is part of our service, designed to prevent misunderstandings and ensure your vision is executed perfectly, leading to on-time delivery and a smooth partnership.

Conclusion

Innovative growth-adjustable baby clothes represent a smart and profitable evolution in children's wear. By integrating features like expandable cuffs and multi-position snaps, these garments offer extended usability, directly addressing a universal parent frustration. For brands, this translates into enhanced customer loyalty, a stronger market position, and improved profit margins. Success in this category hinges on partnering with a manufacturer that possesses the technical expertise, rigorous quality controls, and transparent communication necessary to bring these sophisticated products to market reliably.

If you are looking to develop a line of high-quality, growth-adjustable baby clothing that delivers real value to your customers, we should talk. Our team has the experience and dedication to ensure your project is a success from design to delivery. For a direct conversation about your manufacturing needs, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build the next successful collection together.