As an apparel manufacturer with decades of practice and extensive academic research in textile standards and compliance, I have seen how one missing audit step can cause entire shipments to fail. For children’s clothing, the stakes are even higher: safety, labor rights, and sustainability are non-negotiable. That is why a structured factory audit checklist is essential for buyers sourcing apparel worldwide.

The best clothing factory audit checklists evaluate five areas: documentation, quality management, safety compliance, labor practices, and sustainability performance. Using this framework helps brands minimize risk, build reliable partnerships, and ensure legal compliance.

This article combines academic insights into international standards with field-tested factory experience to outline the most effective clothing factory audit checklists.

Why Are Factory Audits Critical in Apparel Sourcing?

Audits are not just paperwork—they are risk management tools.

They prevent compliance failures, verify safety, and confirm that factories operate ethically.

What Risks Do Audits Help Avoid?

- Product recalls from flammability or chemical safety failures.

- Late shipments due to poor planning or weak systems.

- Legal penalties for using non-compliant dyes or trims.

- Brand damage from labor violations or false certificates.

The SGS and Intertek audit guidelines confirm that most global brands require third-party audits before bulk orders.

Why Are They Crucial for Children’s Clothing?

Children’s apparel is regulated under strict laws like CPSIA in the U.S., REACH in Europe, and OEKO-TEX Standard 100. Audits verify compliance with these rules and protect buyers from legal disputes.

What Are the Core Audit Checklist Categories?

A professional factory audit checklist is structured around five categories.

Each category ensures that suppliers are safe, reliable, and globally compliant.

1. Documentation & Factory Profile

- Business license, export permits, and insurance.

- Certifications: OEKO-TEX, GOTS, ISO 9001.

- Capacity reports: number of lines, daily output, seasonal history.

- Past shipment records verified via ImportYeti.

2. Quality Management

- Raw material inspections and traceability.

- Inline inspection reports for cutting, stitching, finishing.

- Final inspections aligned with AQL standards.

- Lab results for flammability, small parts, and dye fastness.

What Safety and Compliance Standards Must Be Audited?

Safety audits combine workplace and product inspections.

Factories must demonstrate both worker safety and product safety systems.

Why Workplace Safety Audits Matter

- Fire drills, evacuation maps, and first aid readiness.

- Machine safety guards and maintenance logs.

- Ventilation and ergonomic seating for operators.

International ILO conventions guide these safety checks.

Which Product Standards Apply?

- CPSIA for U.S. baby clothing.

- EN 71-3 for saliva and sweat testing in Europe.

- REACH restrictions for hazardous chemicals.

- Reports issued by TÜV SÜD or Bureau Veritas.

How to Audit Labor & Ethical Practices?

Ethical sourcing is now a core buyer requirement.

A proper audit must confirm fair labor practices and the absence of child or forced labor.

What Checks Are Required?

- No workers under legal minimum age.

- Wages and overtime aligned with labor law.

- Contracts and insurance provided to employees.

- Worker interviews for cross-verification.

Which Frameworks Are Trusted?

- BSCI – Business Social Compliance Initiative.

- Sedex SMETA – Ethical sourcing and transparency.

- WRAP – Responsible apparel production.

How to Evaluate Environmental & Sustainability Practices?

Sustainability is no longer optional—it is now a buyer requirement.

Audits must confirm eco-friendly practices, waste management, and sustainable packaging.

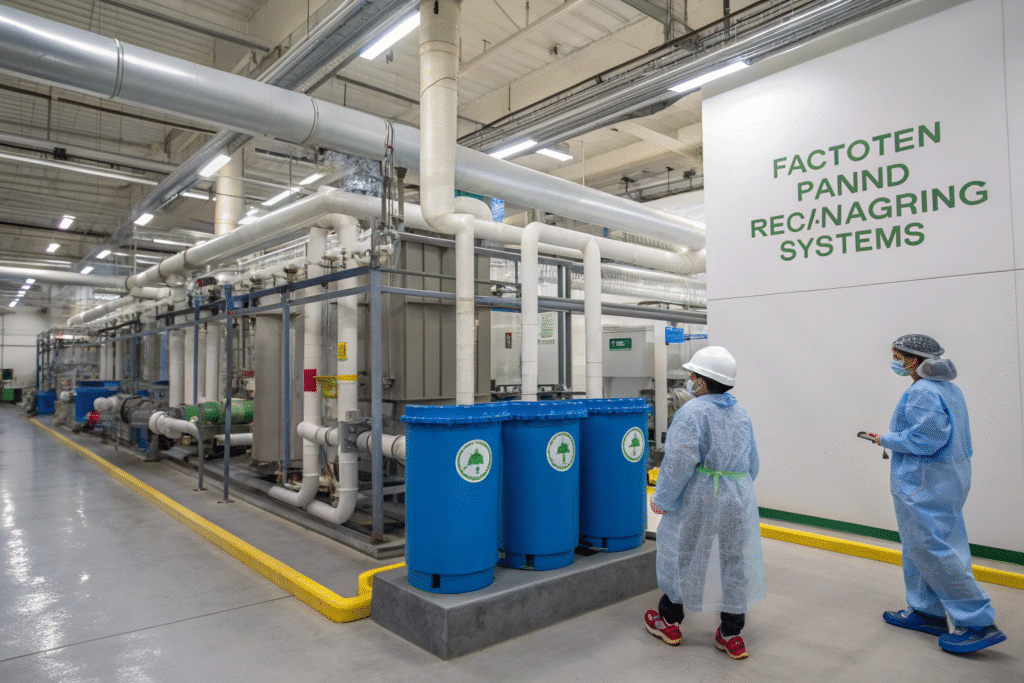

What Environmental Factors Are Audited?

- Wastewater treatment for dyeing and finishing units.

- Energy-efficient machinery and renewable power.

- Recycled LDPE or compostable polybags.

- FSC-certified cartons for garment packaging.

Why Sustainability Audits Matter

A McKinsey Report shows that over 60% of global fashion buyers now demand suppliers with measurable sustainability practices.

Conclusion

The best clothing factory audit checklists cover five areas: documentation, quality, safety, labor, and sustainability. By adopting international frameworks like BSCI, WRAP, and ISO standards, buyers can reduce risk and ensure reliable sourcing partnerships.

At Shanghai Fumao Clothing, we welcome third-party audits and already comply with GOTS, OEKO-TEX, CPSIA, and BSCI standards. If you are preparing to source children’s apparel and need a factory partner who meets global audit requirements, please contact our Business Director Elaine at elaine@fumaoclothing.com.