When global buyers search for children’s wear suppliers, they often discover the same story—delays, inconsistent quality, and poor communication. These challenges cost companies money and weaken brand reputation. Many buyers want a partner they can depend on, not just another factory.

Reliable kidswear manufacturing solves these problems by offering on-time delivery, certified quality, and transparent production that empowers brands to thrive in competitive markets.

At FUMAO TEAM, we focus on being that reliable partner for international buyers. We simplify kidswear production with strong compliance, advanced facilities, and flexible logistics to ensure smooth, long-term cooperation.

Why Is Reliability Critical in Kidswear Manufacturing?

Unreliable kidswear suppliers bring risks that no serious buyer can afford. A single delayed shipment may ruin an entire season’s collection. Poorly inspected fabrics can lead to returns, refunds, and damage to brand credibility. Many sourcing managers know how one weak link in the supply chain can turn into a disaster.

Reliability means consistency—delivering the right products, at the right time, with the right compliance. That is what makes or breaks success in kidswear manufacturing.

What happens when a collection misses the season?

A summer kidswear collection delivered in September loses all relevance. Brands are forced into markdowns or holding dead stock. According to Business of Fashion, seasonality is one of the strongest drivers of profit in fashion. Missing those windows means missing revenue.

Why do buyers demand certified quality?

Global buyers face strict regulations. Certifications like OEKO-TEX and CPSIA are not optional—they are mandatory. Reliable factories like FUMAO TEAM guarantee real, verifiable certifications so brands can sell confidently without fear of recalls or fines.

How Does FUMAO TEAM Deliver Consistent Quality?

Our promise of reliability begins with strict quality assurance. Every order is produced with international standards in mind. We implement multi-stage inspections, from raw fabric to final packaging. This ensures every batch matches buyer expectations exactly.

FUMAO TEAM combines technical expertise, premium materials, and compliance-driven processes to guarantee consistent quality for every shipment.

How do inspections reduce buyer risks?

By inspecting at multiple stages, problems are caught before shipment. For example, we follow ASTM textile testing protocols to check durability and safety. This prevents costly returns or rework after arrival, giving buyers confidence.

Why are premium fabrics essential in kidswear?

Children’s clothing requires fabrics that are soft, durable, and safe. Using trusted suppliers listed on Textile World ensures raw materials meet international standards. This way, buyers know they receive kidswear that parents trust.

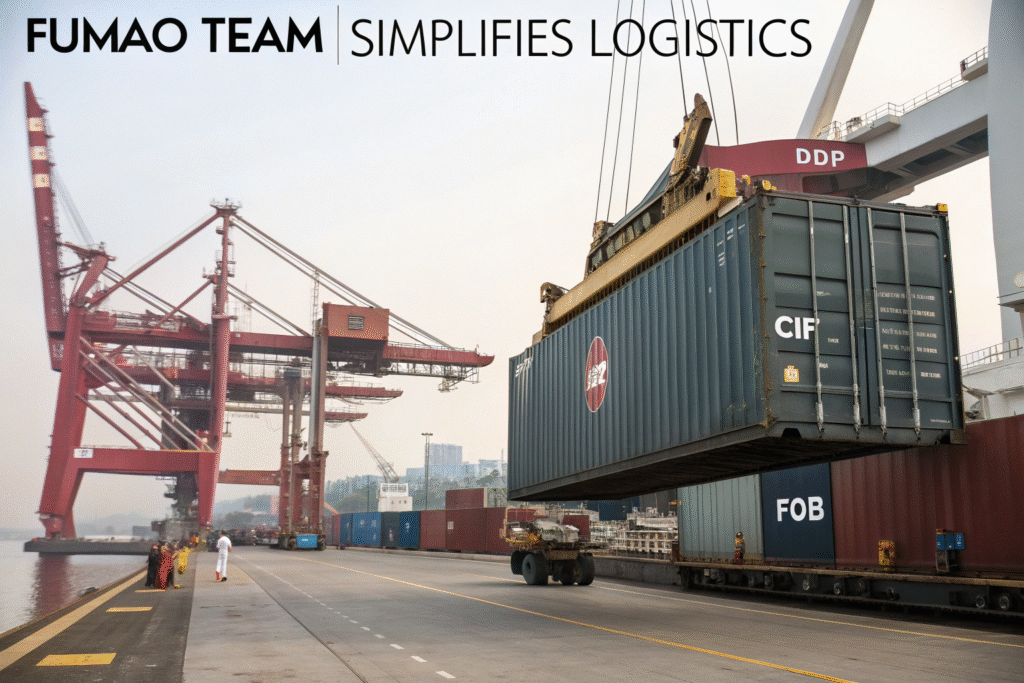

How Do We Simplify Global Logistics for Buyers?

Even when production is flawless, poor logistics can destroy profits. Late customs clearance, misrouted containers, and surprise import fees frustrate buyers. Many factories stop their responsibility at FOB, leaving the buyer to handle complex global shipping.

FUMAO TEAM simplifies logistics with flexible delivery terms like DDP, CIF, and FOB, ensuring products arrive safely, quickly, and without hidden costs.

Why is DDP a game changer for buyers?

DDP means we handle customs clearance and import duties, not the buyer. According to Investopedia, this approach reduces uncertainty and prevents financial surprises. Buyers focus on sales, while we manage the complexity.

How do we prevent costly shipping delays?

We collaborate with trusted global carriers such as Maersk to track schedules and secure priority shipments. By using digital logistics monitoring, we give buyers real-time updates, keeping deliveries predictable and safe.

Why Is a Long-Term Partnership the Smartest Choice?

One-off orders may solve short-term needs, but long-term partnerships bring real growth. Buyers who work with the same reliable factory benefit from smoother communication, faster sampling, and lower risks over time.

At FUMAO TEAM, we see ourselves as strategic partners, not just suppliers. We grow with our clients, helping them scale consistently across seasons.

How does innovation keep brands competitive?

Trends in kidswear change fast. From eco-friendly fabrics to smart designs, brands need fresh ideas. McKinsey’s State of Fashion reports show innovation is central to staying relevant. We integrate new materials and designs so buyers never fall behind.

Why does trust increase profitability?

Stable, reliable partnerships save time and reduce sourcing costs. According to Harvard Business Review, long-term supplier relationships lead to higher profitability. Trust eliminates wasted negotiations and ensures smoother cooperation.

Conclusion

Reliable kidswear manufacturing is not a luxury—it is a necessity for global buyers who want to scale successfully. From certified quality to simplified logistics and innovation-driven production, FUMAO TEAM delivers the consistency brands need.

If you are ready to grow your apparel business with a trusted partner, contact Shanghai Fumao today. Reach out to our Business Director Elaine at elaine@fumaoclothing.com and let us simplify your kidswear production journey.