Finding manufacturers willing to accept low minimum order quantities represents one of the most significant challenges for emerging kids clothing brands. As a factory that specializes in accommodating startups and small batch production, we've developed strategies that make low MOQ manufacturing feasible while maintaining quality and profitability.

To source kids clothing from a factory with low MOQ, you need to target manufacturers specializing in small batches, optimize your order structure, select simple designs with fabric sharing potential, build strategic relationships, and understand the cost trade-offs of small quantity production. Successful low MOQ sourcing requires a different approach than traditional manufacturing, focusing on flexibility, efficiency, and mutual benefit rather than simply seeking the lowest per-unit cost. The right partnership can help emerging brands scale gradually without excessive inventory risk.

What Factory Characteristics Support Low MOQ Production?

Not all manufacturers are structured to accommodate small orders efficiently, making targeted factory selection the critical first step in low MOQ sourcing.

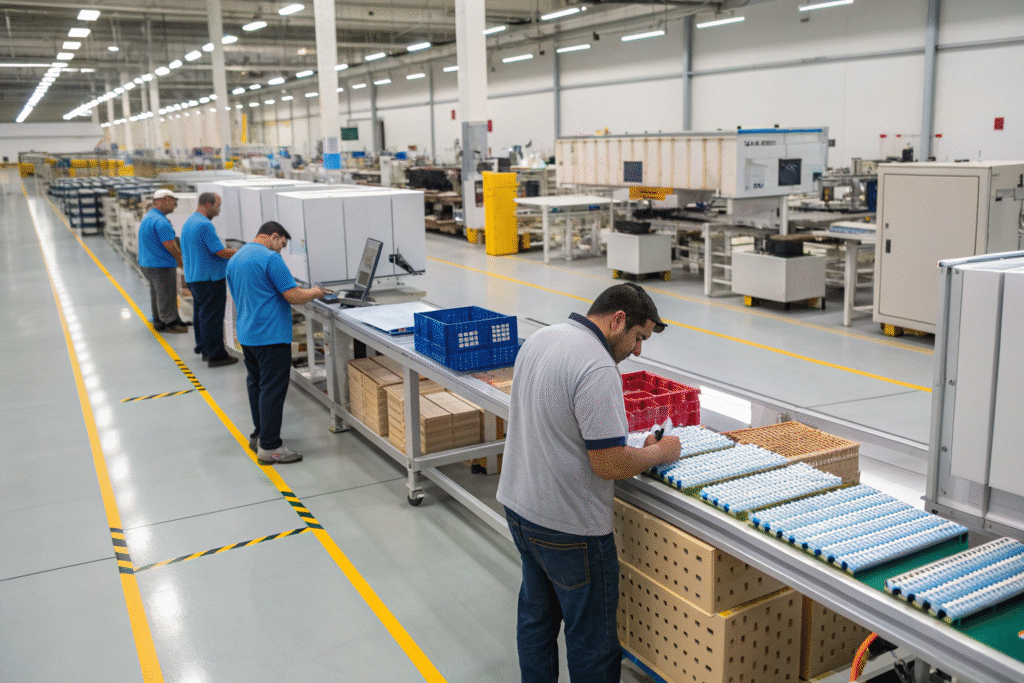

Factories capable of profitable low MOQ production typically share specific operational characteristics, including flexible production lines, quick changeover capabilities, and business models that value long-term relationships over individual order size. Understanding these characteristics helps identify manufacturing partners who view small orders as opportunities rather than inconveniences.

How Do Production Systems Differ for Low MOQ Factories?

Factories specializing in small batches typically employ modular production systems rather than traditional assembly lines, with skilled operators capable of handling multiple garment types and processes. According to the International Apparel Federation's manufacturing analysis, factories using modular systems can efficiently produce batches as small as 50-100 pieces per style, compared to the 500-1000 piece minimums common in traditional mass production. These systems feature versatile equipment, cross-trained workers, and flexible scheduling that accommodates frequent style changes. For children's wear specifically, this flexibility is particularly valuable given the need to produce across multiple sizes and the rapid style changes characteristic of the category.

What Business Models Support Low Minimums?

Manufacturers accepting low MOQs typically structure their business to value long-term customer relationships and growth potential over individual order profitability. Some operate on a tiered pricing model where MOQs decrease as order frequency increases. Others specialize in specific niches where small batches are standard, such as sampling services, limited edition collections, or premium brands producing exclusivity through scarcity. The Fashion Incubator's manufacturing guide identifies that factories focusing on development partnerships rather than transactional relationships are typically more accommodating of small orders, viewing them as investments in future business rather than standalone profit centers.

How Can You Structure Orders for Low MOQ Success?

Strategic order planning and structure can make small quantities more feasible for manufacturers while ensuring you receive production efficiency despite limited volumes.

Order structure significantly impacts a factory's ability to accommodate low MOQs profitably. Thoughtful approaches to style selection, size distribution, and production timing can transform challenging small orders into manageable production runs that maintain quality while controlling costs.

What Order Bundling Strategies Reduce Effective MOQs?

Combining multiple styles in a single production run can achieve individual style MOQs as low as 50-100 pieces while providing the factory with a total order volume that justifies setup costs. This approach works particularly well when styles share common fabrics, components, or construction techniques. According to manufacturing efficiency research from the American Apparel & Footwear Association, factories can reduce changeover time by 60-70% when producing related styles sequentially. For children's wear brands, this might mean developing a capsule collection where multiple styles use the same fabric in different applications, or planning production so that all garments requiring similar specialty stitches are grouped together.

How Does Size Distribution Impact MOQ Feasibility?

Concentrating your size distribution rather than spreading limited quantities across a full size range can make small orders more practical for manufacturers. Instead of producing 20 pieces each in 5 sizes (100 total pieces), producing 50 pieces in 2 best-selling sizes may better serve your market while being more feasible for the factory. The Textile and Apparel Production Management Association notes that factories typically require minimum cut quantities per size to maintain pattern efficiency, often around 25-30 pieces depending on garment complexity. Focusing on your core sizes initially and expanding the size range as your business grows represents a strategic approach to low MOQ production.

What Design Choices Facilitate Low MOQ Manufacturing?

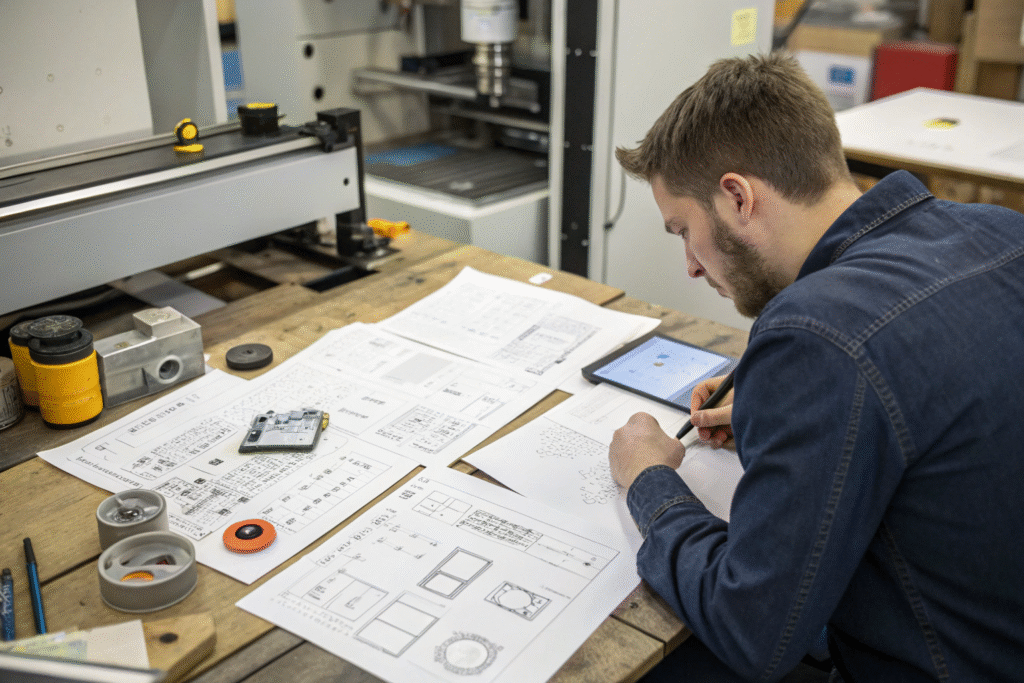

Certain design characteristics naturally lend themselves to small batch production, making strategic design decisions essential for brands operating with limited quantities.

Design complexity directly impacts minimum feasible production quantities, with simpler designs requiring less specialized equipment, fewer operator skills, and shorter setup times. Understanding which design elements facilitate versus complicate small batch production helps create collections that can be manufactured efficiently at low volumes.

Which Construction Methods Work Best for Small Batches?

Simple construction techniques using readily available equipment typically accommodate lower MOQs than designs requiring specialized machines or complex multi-step processes. Basic tees, leggings, and simple woven tops typically have lower minimums than technical outerwear, complex dresses with multiple components, or garments requiring extensive embellishment. The Manufacturing Skills Australia assessment identifies that operators can produce simple garments with minimal training, while complex constructions require specialized skills that factories reserve for larger orders. Starting with straightforward designs and gradually introducing complexity as order volumes increase represents a practical approach for emerging brands.

How Can Fabric Selection Impact MOQ Requirements?

Choosing readily available fabrics from the factory's existing suppliers can significantly reduce MOQs compared to custom-developed materials. Factories maintain relationships with fabric mills that offer quick-ship programs with lower minimums, while custom fabrics typically require meeting the mill's minimum order quantities, which often far exceed what small brands need. The Textile Exchange's material sourcing guide recommends that small brands prioritize GOTS-certified organic cottons and other sustainable fabrics that are increasingly available through distributor stock programs with accessible minimums. Working within the factory's established fabric network rather than insisting on custom materials represents one of the most effective strategies for reducing MOQs.

What Relationship Strategies Support Low MOQ Access?

Building strategic manufacturing relationships rather than transactional supplier interactions can provide access to lower MOQs than would otherwise be available to new or small brands.

Factories are more likely to accommodate challenging small orders for partners they trust and value, making relationship building an essential component of low MOQ sourcing. Demonstrating reliability, growth potential, and fair business practices can convince manufacturers to invest in your business through accommodating production terms.

How Does Communication Style Impact MOQ Flexibility?

Clear, professional communication and realistic expectations make manufacturers more willing to accommodate small orders. Providing complete tech packs, responsive feedback, and realistic timelines demonstrates that you understand manufacturing constraints and respect the factory's time. According to the International Association of Clothing Designers, factories report 40% higher willingness to accommodate small orders for clients who provide thorough specifications and maintain professional communication. This efficiency reduces the factory's non-production time investment, making small orders more economically viable despite the additional setup effort required.

What Partnership Approaches Increase MOQ Flexibility?

Positioning your relationship as a long-term partnership rather than a transactional exchange can significantly increase a factory's willingness to accommodate low MOQs. This might involve sharing your business growth plan, committing to future orders, or offering flexibility on production timing that allows the factory to schedule your order during slower periods. The Fashion Business Institute's sourcing research indicates that manufacturers typically offer 20-30% lower MOQs to clients who demonstrate clear growth trajectories and commitment to developing the relationship beyond individual orders. This partnership mindset transforms the factory from a vendor to a strategic ally invested in your success.

Conclusion

Sourcing kids clothing with low MOQs requires a comprehensive approach that combines targeted factory selection, strategic order planning, design optimization, and relationship building. While low MOQ production typically involves higher per-unit costs, the inventory risk reduction and cash flow benefits often justify the premium for emerging brands. The most successful small brands view their manufacturing partnerships as collaborative relationships rather than transactional arrangements, working together to find solutions that serve both parties' interests.

As you develop your low MOQ sourcing strategy, remember that the right manufacturing partner can grow with your business, gradually increasing capabilities and capacity as your order volumes expand. If you're seeking a children's wear manufacturing partner experienced in low MOQ production and committed to supporting emerging brands, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's discuss how we can help you launch and scale your collection with production quantities that match your business stage while maintaining the quality standards your brand deserves.