Finding reliable suppliers for innovative babywear like hydration-sensing bodysuits can be challenging. You need a partner who understands technology, quality, and strict safety standards. This guide will show you how to source these advanced garments successfully.

Sourcing hydration-sensing baby bodysuits requires identifying manufacturers with expertise in smart textile integration, verifying their compliance with international safety standards, and ensuring they offer end-to-end supply chain management for on-time delivery. This process involves careful evaluation of a factory's technical capabilities, quality control systems, and experience in producing sensor-based baby clothing for the US and European markets.

Navigating the world of smart baby clothing can feel complex. But with the right approach, you can find a manufacturing partner who delivers both innovation and reliability. Let's explore the key steps to ensure your sourcing journey is a success.

What are the key features of quality hydration-sensing baby bodysuits?

A top-quality hydration-sensing bodysuit does more than just detect moisture. It integrates technology seamlessly while prioritizing the baby's comfort and safety. The best products combine advanced sensors with soft, hypoallergenic fabrics.

The core feature is, of course, the hydration-sensing technology. This typically involves a non-invasive sensor that can monitor a baby's hydration levels. The sensor must be accurate, safe, and comfortable against the baby's skin. It should also be durable enough to withstand multiple washes without losing functionality. The integration of such technology in children's apparel requires a deep understanding of both electronics and textile manufacturing.

Another critical feature is the bodysuit material itself. Since it's for babies, the fabric must be ultra-soft, breathable, and free from harmful chemicals. Look for suppliers who use high-quality, Oeko-Tex certified fabrics. This certification ensures the textiles are tested for harmful substances. The bodysuit's design should also allow for easy dressing and diaper changes, with features like snap closures. A good manufacturer will balance technological integration with practical, baby-friendly design.

How does the sensor technology work in baby clothing?

The sensor technology in these bodysuits usually relies on lightweight, flexible electronics. These sensors are often woven into the fabric or placed in a dedicated, soft patch. They monitor skin hydration or other vital signs through conductive threads or non-invasive optical sensors. The data is then typically transmitted to a parent's smartphone via a small, removable Bluetooth module. The key for manufacturers is to make this technology unobtrusive and safe, ensuring no hard components press against the baby's skin. This requires expertise in smart textile manufacturing, a specialty for advanced children's wear producers.

The reliability of this technology is paramount. When sourcing, you must ask suppliers about the type of sensors they use and their data accuracy. Inquire about the power source and how the electronic components are protected during washing. A reputable manufacturer will have conducted rigorous testing on their smart clothing. They should provide documentation on the sensor's performance and durability. Partnering with a factory that has a strong background in kids' wear ensures they understand the unique demands of creating functional yet gentle apparel for the youngest users.

What material is best for sensitive baby skin?

For sensitive baby skin, natural, breathable, and certified fabrics are best. Organic cotton is a top choice because it is soft, hypoallergenic, and highly absorbent. It allows the skin to breathe, reducing the risk of irritation and rashes. Bamboo viscose is another excellent material. It is incredibly soft, temperature-regulating, and has natural antibacterial properties. Both materials are ideal for the base fabric of a hydration-sensing bodysuit as they provide comfort and functionality.

The choice of material also impacts the integration of technology. The fabric must be able to house sensors comfortably without compromising its softness. This is where a manufacturer's expertise in fabric selection and garment construction becomes critical. At our factory, we prioritize GOTS certified organic cotton and Oeko-Tex Standard 100 certified fabrics for all our baby apparel. These certifications are your assurance that the materials meet the highest global standards for safety and are free from harmful chemicals. This is a non-negotiable aspect of producing high-quality baby clothing that parents and brands can trust.

How to verify a supplier's quality and certifications?

Verifying a supplier's quality and certifications is a critical step that protects your brand and your customers. It goes beyond just checking a website; it requires due diligence to ensure their claims are legitimate and backed by evidence.

Start by requesting official certification documents directly from the supplier. For baby clothing, key certifications include Oeko-Tex Standard 100, which verifies that textiles are free from harmful substances. For organic claims, look for GOTS certification. Don't just accept copies of certificates; verify their authenticity by checking the unique license number on the certifying body's official website. This simple step can prevent issues with falsified documents. Also, ask for detailed test reports from third-party labs, which provide unbiased data on fabric safety, colorfastness, and durability.

Another powerful method is to order a pre-production sample for independent testing. This allows you to validate the supplier's quality claims yourself. You can send the sample to a lab like Bureau Veritas to check for lead, phthalates, and formaldehyde. Furthermore, insist on a factory audit report. Many professional inspection companies can conduct these audits on your behalf to verify the supplier's production capabilities, working conditions, and quality control processes. This multi-layered approach gives you a comprehensive view of the supplier's true standards.

Which international safety standards are mandatory?

For baby bodysuits entering the US and European markets, compliance with specific mandatory safety standards is non-negotiable. In the United States, the Consumer Product Safety Improvement Act sets strict limits on lead and phthalates in children's products. All children's clothing must also comply with flammability standards. For Europe, the REACH regulation restricts hazardous chemicals, and the CPSR is a key requirement for children's apparel, ensuring it meets safety standards for physical and mechanical properties, such as the security of small parts like snaps.

Beyond these legal requirements, adhering to voluntary standards like Oeko-Tex Standard 100 is a strong sign of a quality-focused supplier. This standard is globally recognized and tests for a comprehensive list of harmful substances. For the physical safety of the garment, standards like EN 14682 specify requirements for cords and drawstrings in children's clothing, a crucial detail for design. A trustworthy manufacturer will not only be familiar with these standards but will have a dedicated compliance team to ensure every batch of goods meets these critical requirements for your target market.

What questions to ask about their quality control process?

Asking the right questions reveals the depth of a supplier's commitment to quality. Go beyond generic assurances and ask for specifics. Here are key questions to pose:

- "Can you walk me through your inline and final inspection procedures?"

- "What is your AQL standard for baby clothing, and what is your typical defect rate?"

- "How do you test the colorfastness and shrinkage of the fabrics you use?"

- "What is your process for checking the safety and functionality of the integrated sensors?"

- "How do you handle a situation when a quality issue is found during production?"

A professional supplier will have clear, documented answers. They should explain their multi-stage inspection system, which includes checking raw materials, monitoring the production line, and conducting a final random inspection before shipment. They should be transparent about their Acceptable Quality Limit, a statistical tool used in inspections. For smart clothing, ask about their specific testing protocols for the electronic components, including water resistance and durability after repeated washing. Their willingness to provide detailed answers is a strong indicator of a robust and reliable quality control system.

What is the typical production timeline for smart baby wear?

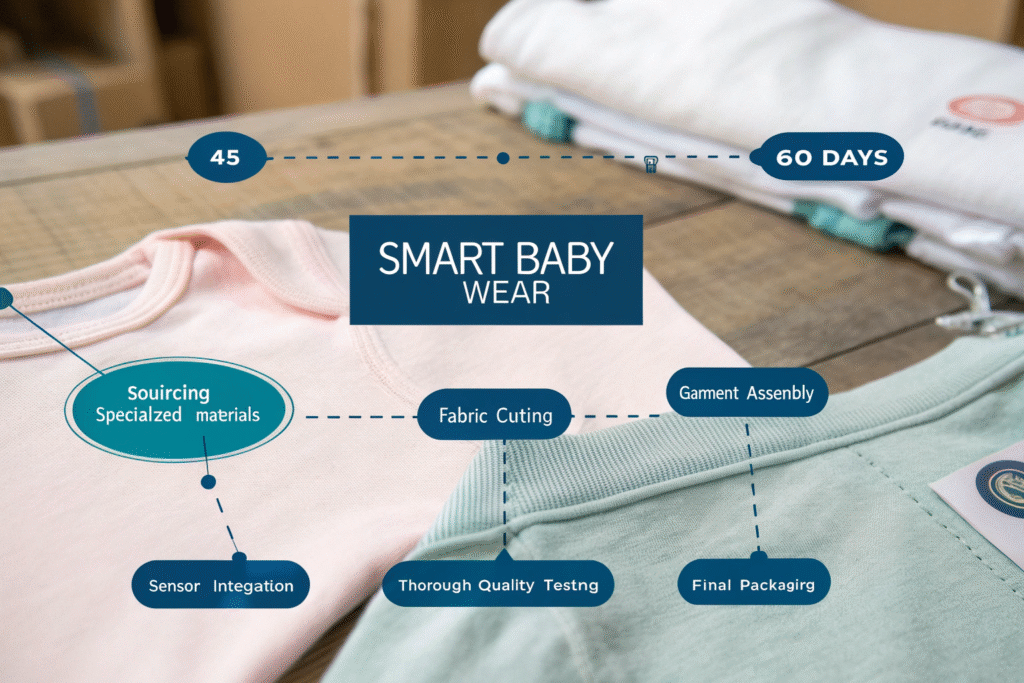

The production timeline for smart baby wear is generally longer than for standard apparel due to the added complexity of integrating technology. A realistic timeline from order confirmation to shipment is typically 45 to 60 days. This period accounts for sourcing specialized materials, fabric cutting, garment assembly, sensor integration, rigorous quality testing, and final packaging.

The timeline can be broken down into key phases. The first phase is material and component sourcing, which can take 10-15 days, especially if custom organic fabrics or specific sensors are needed. The second phase is production and assembly, which usually requires 15-20 days. This is followed by the crucial phase of quality control and testing, which can take 7-10 days for smart wear to ensure both the garment and electronics meet standards. Finally, packaging and logistics require another 5-7 days. A reliable manufacturer will provide you with a detailed schedule and maintain regular communication at each milestone to ensure transparency.

How can you prevent delays in the supply chain?

Preventing delays requires proactive planning and a strong partnership with your supplier. One of the most effective strategies is to place your order well in advance of your needed delivery date, considering potential bottlenecks. Work with a manufacturer that has strong relationships with their own material suppliers and maintains a buffer stock of common fabrics. This mitigates risks from raw material shortages. Also, choose a supplier with in-house production lines, like our factory with 5 dedicated lines. This gives them direct control over the schedule, unlike companies that outsource production to third parties.

Clear and timely communication is your best tool against delays. Provide all technical details, label artwork, and packaging instructions upfront to avoid revisions later. Use a secure payment method that is efficient for both parties. Finally, partner with a manufacturer that has expertise in international logistics. They should be able to recommend the best shipping methods and handle customs clearance efficiently, using reliable Incoterms like DDP to simplify the process for you. A supplier that manages the entire supply chain is less likely to experience disruptive delays.

What are the key milestones in the manufacturing process?

Understanding the key milestones helps you track progress and manage your inventory planning. A transparent manufacturer will keep you informed at each of these stages:

| Milestone | Description | Typical Duration (After Order Confirmation) |

|---|---|---|

| 1. Material Sourcing | Sourcing fabric, threads, snaps, and sensors. | 5-10 days |

| 2. Prototype/Sample Approval | Creating and approving a pre-production sample (if required). | 10-15 days |

| 3. Production Launch | Fabric cutting and garment assembly begins. | 15-20 days |

| 4. Quality Check & Testing | In-line inspections and final product testing for garments and sensors. | 30-35 days |

| 5. Final Inspection | A comprehensive AQL-based check of the finished order. | 35-40 days |

| 6. Shipping & Logistics | Packaging, booking cargo space, and shipment departure. | 45-60 days |

These milestones provide a clear framework. After you approve the sample and confirm the order, the factory will procure all materials. The production launch is a major step, where bulk cutting begins. The quality check milestone is critical, especially for smart wear, where both the apparel and technology are tested. The final inspection is your last checkpoint before goods are shipped. A professional supplier will provide regular updates and even photos or reports at these key stages, giving you peace of mind that your order is on track.

Why is DDP shipping crucial for US importers?

For US importers, DDP shipping is a game-changer. It simplifies the complex process of international shipping and provides cost certainty. DDP means the seller is responsible for all costs and risks until the goods are delivered to your designated warehouse in the US. This includes export formalities, international freight, insurance, and most importantly, all destination charges like customs clearance, duties, and taxes.

The primary benefit of DDP is predictability. You receive one all-inclusive price from your manufacturer, so there are no surprise fees upon your shipment's arrival in the US. This makes your financial planning and cost calculation for your products much more accurate. It also saves you the time and hassle of having to hire a customs broker yourself and deal with US customs regulations. For businesses that may not have a dedicated logistics team, DDP service is an invaluable resource that allows you to focus on sales and marketing, not international trade compliance.

How does DDP simplify customs and logistics?

DDP simplifies customs and logistics by making your supplier the single point of responsibility. The supplier's logistics team handles everything. They will prepare all necessary shipping documents, such as the commercial invoice, packing list, and certificate of origin. They work with their freight forwarder to book sea or air freight and manage the journey to the US port. Upon arrival, their designated customs broker takes over to file the ISF, pay the import duties, and clear the goods through US Customs and Border Protection.

This end-to-end management means you are insulated from the complexities. You don't need to understand the intricacies of the Harmonized Tariff Schedule or worry about filing paperwork incorrectly, which can lead to fines or shipment holds. Your role is simply to provide your delivery address and any specific warehouse requirements. Once the goods clear customs, the supplier arranges for the final trucking to your door. This streamlined process drastically reduces the administrative burden on your team and minimizes the risk of logistical errors that could delay your inventory.

What are the cost benefits of using a DDP supplier?

The cost benefits of using a DDP supplier are significant, though sometimes hidden. While the unit price from a DDP supplier might appear slightly higher than one using EXW terms, the total landed cost is often more competitive and is certainly more predictable. With DDP, you avoid unexpected expenses such as:

- Customs Brokerage Fees: These can vary widely between brokers.

- Port Handling Fees: Charges for handling at the US port can be unpredictable.

- Duty and Tax Variations: Your supplier calculates and includes these upfront.

- Last-Minute Surcharges: Fuel surcharges and other freight-related fees are included.

This upfront costing prevents budget overruns. It also saves you money indirectly by freeing up your staff's time. You won't need to pay an employee or hire a logistics expert to manage the import process. Furthermore, a reliable DDP supplier has the volume and experience to negotiate better rates with shipping lines and trucking companies, savings that can be passed on to you. This model turns a variable and complex cost center into a fixed, manageable line item in your budget.

Conclusion

Sourcing hydration-sensing baby bodysuits successfully hinges on choosing the right manufacturing partner. This means finding a factory with proven expertise in smart textiles, rigorous quality control, and a commitment to meeting international safety standards. By focusing on these key areas—product features, supplier verification, timeline management, and streamlined DDP logistics—you can confidently bring innovative and reliable products to your market. A strong partnership with your manufacturer is the foundation for navigating the complexities of sourcing advanced children's wear.

Ready to partner with a reliable manufacturer for your smart baby clothing line? Let's discuss your specific needs for hydration-sensing bodysuits. Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to start a conversation about your next successful order.