Buttons are widely used in baby clothing because they add style and functionality. However, they also present potential choking hazards if they are not designed, attached, or tested properly. For parents, this risk is unacceptable, and for brands, it can lead to recalls, negative publicity, and even lawsuits.

The most effective way to prevent button hazards in baby wear is to use certified safe materials, follow strict attachment standards, perform rigorous testing, and consider alternative fastening methods. By combining careful design with compliance, manufacturers can ensure garments remain both safe and attractive.

From years of working with international children’s wear buyers, I have seen that safety always comes first. When a product meets global standards, it not only protects babies but also builds trust with parents and strengthens a brand’s reputation.

Why Are Buttons Risky in Baby Clothing?

To prevent hazards, manufacturers must first understand why buttons can be dangerous. Buttons are small, and if they detach, they may cause choking.

What causes button detachment?

Buttons often detach because stitching is weak, materials are brittle, or garments undergo frequent washing. Since babies naturally tug at their clothes, poorly secured buttons can loosen quickly.

Why is detachment so dangerous?

When a button detaches, it can become a choking hazard. Babies instinctively put small objects in their mouths. As a result, one loose button can create life-threatening danger. According to the CPSC (Consumer Product Safety Commission), choking remains one of the leading causes of infant injuries.

What Standards and Certifications Apply?

Because button safety is a global concern, strict standards regulate children’s clothing. These rules define acceptable materials, attachment strength, and testing procedures.

Which standards are most important?

- EN 71-1 (Europe): Requires testing of small parts to ensure no choking risks.

- ASTM F963 (U.S.): Covers mechanical hazards, including button attachment strength.

- CPSIA (U.S.): Ensures buttons and other components are free from harmful chemicals.

How do certifications protect buyers?

Certifications such as OEKO-TEX® prove that fabrics and buttons are non-toxic. Compliance documents also protect brands from liability. Therefore, certification is both a safety measure and a business safeguard.

How Can Manufacturers Prevent Hazards in Production?

Understanding standards is not enough. Manufacturers must implement preventive practices during production to ensure compliance.

Which sewing techniques improve safety?

Factories should use lock-stitch or cross-stitch methods with reinforced threads. Heat-sealed buttons add extra durability. International standards require buttons to withstand pull forces of at least 90N, and only reinforced stitching can meet this requirement consistently.

How do inspections reduce risk?

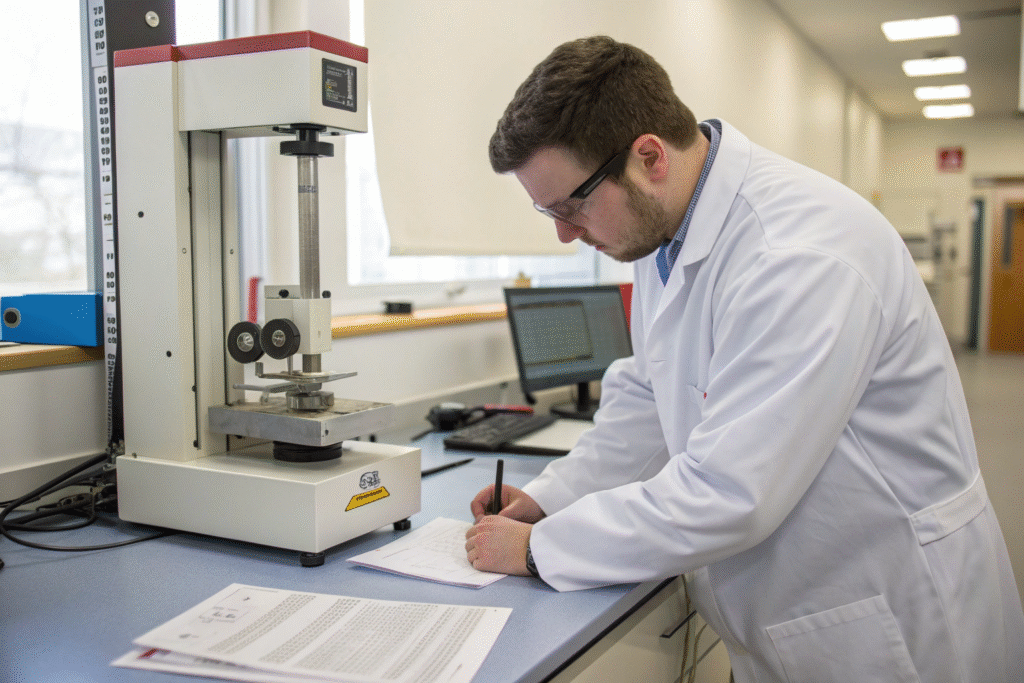

Inspections include button pull tests, which apply force to check durability. Visual checks confirm alignment and stitching density. Because inspections combine mechanical testing and manual checks, they greatly reduce the chance of weak attachments reaching the market.

What Alternatives to Buttons Are Safer?

While buttons can be secured safely, many brands choose alternative fastening systems that reduce risk altogether.

Which fasteners are commonly used instead of buttons?

- Snaps: Secure, easy for parents, and difficult for babies to remove.

- Zippers: Safe if covered with protective fabric flaps.

- Velcro: Lightweight and adjustable, although less durable after repeated washing.

How do these alternatives compare?

Snaps are most common in babywear because they combine safety with convenience. Zippers are best for outerwear, while Velcro is popular in shoes and accessories. In every case, these alternatives reduce choking risks compared to detachable buttons.

Conclusion

Preventing button hazards in baby wear requires a logical sequence of actions: first, understand why buttons pose risks; next, apply global safety standards; then, implement strong production techniques; and finally, consider safer alternatives where appropriate. Each step builds on the previous one to create safe garments.

At Shanghai Fumao Clothing, we strictly follow international safety standards, conduct pull tests on all garments, and offer alternative fastening options for buyers. With these practices, we ensure every product is safe, durable, and trusted by parents.

📩 Contact our Business Director Elaine at elaine@fumaoclothing.com to learn how we can produce safe and certified babywear for your brand.