Accurate demand forecasting is no longer a luxury; it's a necessity for survival and growth in the competitive kids' wear market. Getting it wrong means either being stuck with dead stock or missing out on crucial sales, both of which directly impact your bottom line. As a manufacturer partnering with numerous US brands, we've seen how precise forecasting separates thriving businesses from struggling ones. This guide will walk you through practical, actionable strategies to predict demand more accurately for your children's fashion line.

Mastering demand forecasting is the key to optimizing inventory, maximizing profitability, and ensuring your kids' wear brand meets market expectations seamlessly. It involves a blend of data analysis, market intuition, and strong supply chain collaboration. By the end of this article, you will have a clear framework to refine your forecasting process, reduce risks, and build a more resilient business.

Let's dive into the core components that will transform how you predict demand for your next collection.

What Are The Key Methods For Kids Wear Demand Forecasting?

Understanding the different forecasting methods is the first step toward accuracy. Many brands rely on guesswork, but successful ones use a mix of quantitative and qualitative approaches. Choosing the right method can significantly reduce overstock and stockouts.

The most effective approach is often a hybrid model. This combines historical sales data analysis with real-time market intelligence. For established brands, looking at past performance of similar items is crucial. For new lines, you must rely more on market trends and pre-orders. The goal is to create a balanced view that isn't overly dependent on a single data point.

Why is historical sales data analysis fundamental?

Historical data is your most objective teacher. Start by analyzing sales figures from previous seasons, focusing on items similar to your new designs. Look for patterns related to product categories, colors, and sizes that performed well. Use an ERP system to track this data efficiently. This analysis helps establish a baseline forecast. It tells you what typically sells and during which months. However, remember that past performance doesn't guarantee future results, especially in fast-changing children's fashion.

How can you leverage market trend research?

While historical data looks backward, market trend research looks forward. This involves monitoring fashion trends on platforms like Instagram and TikTok. It also includes attending trade shows and reviewing industry reports. For kids' wear, factors like popular cartoon characters, color of the year, and shifts in fabric preferences (e.g., towards organic cotton) are critical. This qualitative method helps you anticipate sudden shifts in consumer demand that historical data might miss, allowing you to be proactive rather than reactive.

How To Use Data Analytics To Improve Forecast Accuracy?

Raw data is abundant, but insights are precious. Leveraging analytics moves your forecasting from educated guesses to data-driven decisions. Brands that master this can respond agilely to market changes.

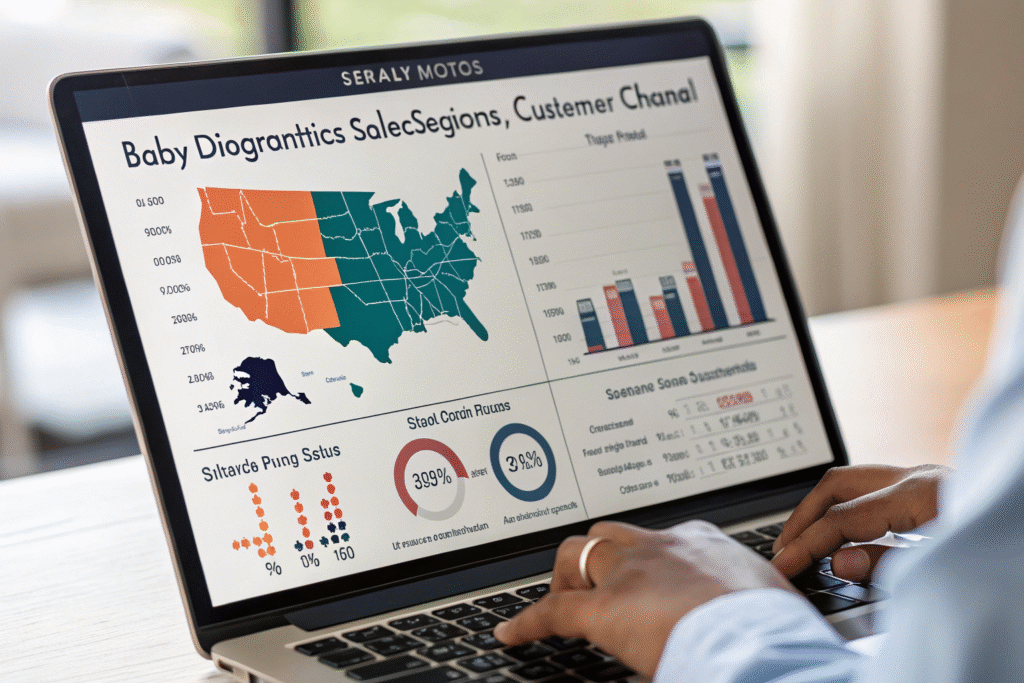

Data analytics allows you to segment your data for deeper insights. Instead of looking at overall sales, break down the information by region, customer demographics, and sales channel. You might discover that certain styles sell better in specific US states or that a particular size chart is preferred for baby & toddler apparel. This granular view prevents you from making broad, inaccurate assumptions.

What role does sell-through rate play?

The sell-through rate is a key performance indicator. It measures the percentage of inventory sold in a given period compared to the amount received from your manufacturer. A high rate indicates strong demand and potential under-ordering. A low rate signals weak demand and risk of overstock. By tracking this rate for each product line, you can make swift adjustments to future production orders. This is vital for managing seasonal collections and avoiding end-of-season markdowns.

How can customer feedback and pre-orders guide production?

Direct customer input is invaluable. Before placing a large bulk order, use pre-orders to gauge demand. This is a low-risk strategy to validate your forecasts. Additionally, actively monitor product reviews and feedback on your website and social media. Customers often comment on desired sizes, colors, or styles they wish were available. This real-time qualitative data provides early signals that can fine-tune your production plans with your clothing manufacturer, ensuring you produce what the market actually wants.

What Factors Influence Demand In The Children's Clothing Industry?

Demand doesn't exist in a vacuum. It's shaped by a complex web of external factors. Recognizing these influences helps you anticipate fluctuations and plan more effectively.

The children's wear market is particularly sensitive to several key factors. Economic conditions, such as consumer spending power, directly affect sales. Seasonality is another major driver, with back-to-school and holiday periods creating predictable peaks. Furthermore, safety standards and certification requirements can influence parent purchasing decisions, making compliance a key demand driver.

| Factor | Impact on Demand | Example |

|---|---|---|

| Seasonal Shifts | Creates predictable peaks and troughs. | High demand for jackets in fall. |

| Economic Climate | Affects overall consumer spending. | Demand may shift to value-focused options during a downturn. |

| Social Media Trends | Can cause sudden, viral demand for specific styles. | A celebrity's child wearing a particular style. |

| Safety Regulations | Builds trust and can be a unique selling point. | Increased demand for OEKO-TEX certified garments. |

How do seasonal trends impact your inventory planning?

Seasonality is one of the most powerful forces in kids' wear. Your inventory plan must be synchronized with the calendar. For instance, you need summer collections to arrive in spring and winter collections in early fall. Failure to align production and shipping lead times with these seasons means missing the entire selling window. Working with a manufacturer that offers DDP (Delivered Duty Paid) services can simplify this by providing a predictable timeline from the factory floor to your warehouse.

Why are safety and certification non-negotiable?

For parents, safety is the top priority. Certifications like CPSC in the US or CE marking in Europe are not just legal hurdles; they are powerful marketing tools. Demand can be severely impacted if your products lack the necessary certifications. Conversely, promoting your adherence to international quality assurance standards can become a significant competitive advantage, justifying a premium price point and building unwavering brand trust.

How To Build A Flexible Supply Chain For Fluctuating Demand?

A perfect forecast is impossible. Therefore, building a supply chain that can adapt to unexpected changes is your ultimate competitive edge. Agility prevents forecast errors from becoming business crises.

A flexible supply chain is characterized by transparent communication, multiple sourcing options, and reliable logistics partners. It's about having a system that can accelerate when demand spikes and slow down without punitive costs when demand softens. This resilience is built on strong partnerships with your manufacturers.

What is the benefit of working with an agile manufacturer?

An agile manufacturer is one that can handle both large and small minimum order quantities (MOQs). This allows you to place a smaller initial order to test the market. Then, you can reorder quickly for fast-moving items. We implement this for our partners by maintaining a strategic stock of key fabrics and operating multiple production lines. This setup enables us to react swiftly to your "re-order" calls, preventing stockouts during peak demand periods.

How can DDP shipping simplify your logistics?

DDP Incoterms are a game-changer for importers. With DDP, your supplier handles the entire logistics process, including shipping, insurance, and import duties. This provides you with a single point of contact and a predictable, all-inclusive cost. It eliminates the logistical headaches and unexpected fees that can cause major delays. On-time delivery becomes more reliable, ensuring your products hit the shelves exactly when needed, which is critical for managing demand fluctuations and protecting your profit margins.

Conclusion

Mastering demand forecasting for your kids' wear line is a continuous journey of analysis, adaptation, and partnership. By employing a mix of data-driven methods, understanding market influences, and building a resilient supply chain, you can significantly reduce inventory risks and capitalize on sales opportunities. Remember, the goal is not perfection, but progressive improvement in predicting what your customers will want next.

The strategies outlined here are the very ones we use to help our partners build successful and sustainable children's wear brands. If you're looking for a manufacturing partner that provides not just top-quality production but also valuable insights to help you forecast and grow, let's start a conversation. For a seamless customization experience and to discuss your next order, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We are here to empower your brand in this dynamic market.