Finding the right manufacturer for kids' sports wear is a specialized quest. This isn't about making cute t-shirts; it's about engineering garments that can withstand rigorous activity, manage sweat, provide freedom of movement, and meet high safety standards—all while being comfortable on a growing, sensitive body. As a manufacturer who has navigated this niche, I can tell you that the partner you choose will make or break the performance, durability, and ultimate success of your line.

To find the right manufacturer for kids sports wear, you must identify factories with proven expertise in technical fabrics (like moisture-wicking polyesters, compression blends, and breathable mesh), mastery of performance-specific construction (flatlock seams, gussets, strategic ventilation), and experience complying with the strict safety and quality standards required for active children's apparel.

The search requires a filter that goes beyond general apparel capabilities. Let's break down the targeted steps to secure a manufacturing partner that can execute your vision for high-performance kids' wear.

What Technical Expertise is Non-Negotiable for Sportswear?

The foundation of sportswear is fabric science and construction engineering. A manufacturer for everyday kids' clothes may lack the machinery, knowledge, and sourcing connections for performance apparel. You need a partner who speaks the language of functionality.

Non-negotiable expertise includes deep knowledge of synthetic performance fabrics (polyester, nylon, spandex blends), experience with moisture management and quick-dry technologies, skill in implementing ventilation systems (mesh panels, laser-cut holes), and proficiency with durable, chafe-free stitching techniques like flatlock and coverstitch seams.

How to Assess a Factory's Fabric Sourcing and Development Capability?

Don't just ask if they use "dry-fit" fabric. Drill deeper. Request a list of their performance fabric suppliers—reputable mills like Polartec, Toray, or Xtep. Ask if they have in-house fabric testing for pilling, colorfastness to sweat and chlorine, and UV protection. Can they develop custom blends for you? A strong manufacturer will have a dedicated fabric sourcing team and samples of various moisture-wicking, compression, and thermal regulation fabrics on hand. Their ability to advise on the right fabric for a soccer jersey versus a gymnastics leotard is a key indicator of their specialized knowledge. Resources like the Textile Exchange can help you understand material standards they should be referencing.

Why is Construction Expertise in Flatlock Seams and Gussets Critical?

The construction of a garment determines its comfort and durability during movement. Flatlock seams are essential—they lie flat against the skin, preventing irritation and chafing during repetitive motion. Coverstitch seams are used for hems on stretch fabrics to allow for elasticity without breaking threads. Additionally, look for experience with gussets (diamond-shaped fabric inserts at the crotch or underarm) that increase range of motion, and raglan sleeves that allow for better arm movement. Ask to see samples of their previous sportswear work and physically examine the seam quality and layflat construction. This is a tangible check of their technical garment construction prowess.

How to Verify Compliance with Safety and Performance Standards?

Children's sportswear is subject to intense scrutiny. It must be safe (no strangulation hazards, compliant with flammability standards for certain activities), durable enough for play, and perform as advertised. Certifications and testing protocols are your objective proof.

Verification requires ensuring compliance with general children's wear safety (like CPSIA in the US and EN 14682 for drawstrings in the EU), as well as specific performance claims. The factory should facilitate or conduct tests for moisture vapor transmission rate (MVTR), colorfastness to perspiration and chlorinated water, and fabric strength.

What Safety Standards Specifically Apply to Activewear for Kids?

Beyond general apparel rules, activewear has specific concerns. Drawstrings on hoodies are heavily regulated; many brands opt for snap-away designs or omit them entirely. For sleepwear-like athletic leisurewear, flammability standards may apply. Chemical compliance is critical, as sweat can cause dyes and finishes to leach. The factory must be adept at designing within these constraints. They should be familiar with standards like the Consumer Product Safety Improvement Act (CPSIA) and have a process for tracking component compliance (fabrics, threads, elastics, prints). Always request recent, product-specific test reports from accredited labs like SGS or Intertek.

How are Performance Claims Like "Moisture-Wicking" Validated?

Marketing terms must be backed by data. A credible manufacturer will understand and facilitate performance testing. Key tests include:

- Moisture Management Test (AATCC 195): Measures how fabric transports liquid sweat.

- Drying Rate Test: How quickly fabric loses moisture.

- Colorfastness to Perspiration (AATCC 15): Ensures dyes don't run with sweat.

- Seam Strength Test: Ensures stitches hold under stress.

Ask potential manufacturers if they have in-house equipment for basic tests or partnerships with labs to conduct this verification. Their willingness and ability to provide this data separates true technical partners from basic sewers. This is core to quality assurance in activewear.

How to Evaluate a Manufacturer's Experience with Key Sportswear Categories?

Not all sportswear is the same. The needs of a youth basketball uniform differ from those of a toddler's swimwear or a child's base layer for skiing. Look for manufacturers with a portfolio demonstrating experience in your specific category.

Evaluate their experience by reviewing samples from similar categories, asking about their minimum order quantities (MOQs) for technical items, understanding their lead times for complex constructions, and gauging their knowledge of category-specific details like chlorine resistance for swimwear or abrasion resistance for skatewear.

What Should You Look for in a Manufacturer for Team Uniforms?

Team uniform manufacturing is a discipline of its own. It requires precision in color matching across separate garment pieces (jerseys and shorts) and consistency over multiple production runs (for re-orders). They must excel at applied graphics—durable screen printing, heat transfer, or embroidered logos that withstand washing and abrasion. Ask about their process for handling individual name and number customization on small batch orders. Logistics are also key; can they ship directly to a team or league coordinator? Their experience in this team sports apparel niche is vital for a smooth operation.

How is Swimwear or Dancewear Manufacturing Unique?

These categories demand extreme specialization:

- Swimwear: Requires fabrics with excellent chlorine and UV resistance (like PBT or Polyester/Spandex blends). Construction involves using latex-free elastic and specialized seam sealing (ultrasonic welding or careful stitching with waterproof thread) to prevent unraveling in water. The factory must understand these fabric and construction nuances intimately.

- Dancewear (Gymnastics, Ballet): Demands high-stretch nylon/Lycra® blends for a second-skin fit and freedom of movement. It requires precision in cutting and sewing to ensure the garment recovers its shape and provides moderate compression. Experience with sheer meshes, velvet burns, and delicate elastics is a must.

A manufacturer's sample portfolio should clearly showcase successful projects in these exact categories.

What Are the Realistic Cost and Timeline Considerations?

Technical sportswear has a different cost structure and timeline than basic apparel. The fabrics are more expensive, the construction is more labor-intensive, and the testing adds time and cost. Understanding this from the outset prevents budget overruns and missed season deadlines.

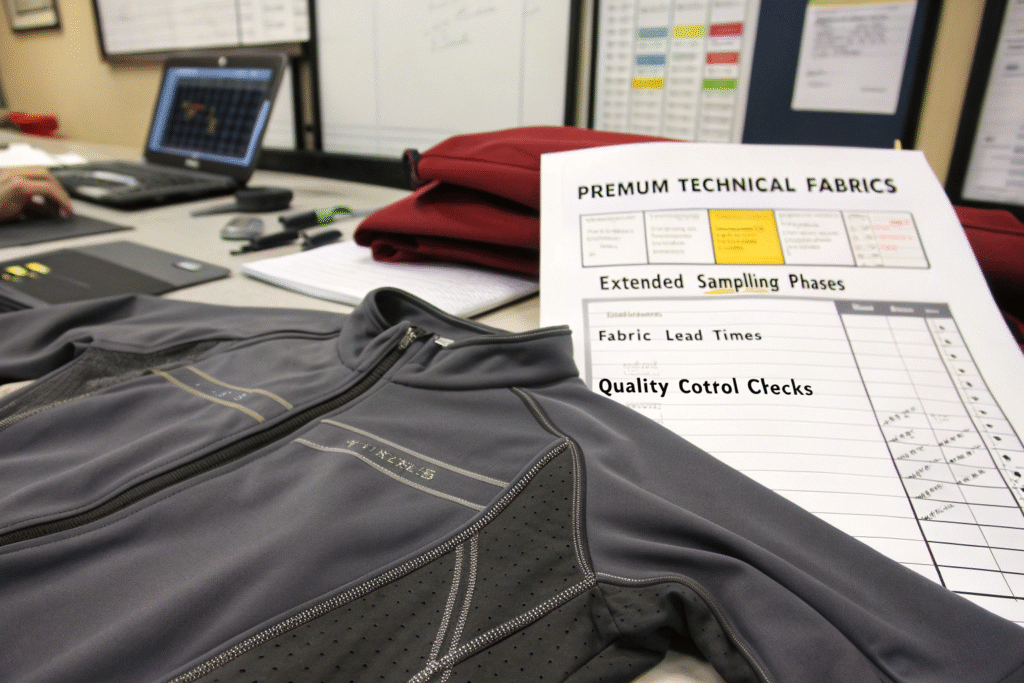

Realistic costs must account for premium technical fabrics, complex construction labor, performance testing fees, and often higher shipping costs due to synthetic fabric weight. Timelines must include extended sampling phases for fit and function approval, fabric lead times, and thorough pre-shipment quality control.

How Do Technical Fabrics and Construction Impact Unit Cost?

The cost breakdown is revealing. Performance fabrics (e.g., moisture-wicking polyester with antimicrobial finish) can be 2-3 times more expensive than basic cotton jersey. Specialized elastics and components (e.g., gripper elastic for waistbands) add cost. Labor is higher because flatlock sewing machines operate slower than overlook machines, and attaching multiple panels (mesh, main fabric, binding) is time-consuming. A manufacturer should provide a transparent costing sheet that breaks down fabric, labor, trims, and testing. Be wary of a quote that seems too close to basic apparel pricing.

What is a Typical Development Timeline for a New Sportswear Style?

Rushing sportswear development leads to failure. A responsible timeline looks like:

- Fabric Sourcing & Approval: 4-6 weeks (longer for custom development).

- Technical Design & Pattern Making: 2-3 weeks.

- Fit Samples (Multiple Rounds): 3-4 weeks. Fit is critical for performance, so multiple rounds are common.

- Performance Testing of Approved Sample: 2-3 weeks.

- Bulk Fabric Production & Delivery: 4-6 weeks.

- Production & QC: 4-5 weeks.

Total: ~20-27 weeks from concept to shipment. For complex items or new factory relationships, add buffer time. This underscores the need for early planning and a manufacturer with efficient project management systems.

Conclusion

Finding the right kids' sports wear manufacturer is a process of finding a technical partner, not just a production facility. It requires vetting for specialized fabric knowledge, engineering-level construction skills, rigorous compliance protocols, and category-specific experience. The goal is to align with a factory that understands that children's activewear must perform on two levels: meeting the high physical demands of sport while adhering to the utmost standards of safety and comfort.

At Fumao Clothing, we have developed expertise in the precise realm of kids' performance wear, from sourcing advanced, safe fabrics to mastering the construction techniques that allow for boundless movement. If you are building a brand in the competitive kids' activewear space, you need a manufacturer who gets the specifics. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can bring your high-performance designs to life.