Finding the right manufacturer for children's performance wear requires specialized knowledge and careful vetting. As someone who has manufactured technical children's apparel for over a decade, I understand the unique challenges of sourcing partners who can deliver both performance features and children's safety standards.

Finding a manufacturer for kids performance wear requires identifying partners with specific expertise in technical fabrics, children's safety compliance, specialized construction techniques, and scalable production capabilities. The ideal manufacturer should demonstrate proven experience in performance categories, understand children's unique needs, and offer comprehensive services from fabric sourcing to quality assurance.

The search process involves multiple verification steps to ensure your manufacturer can meet the demanding requirements of performance wear while maintaining children's product safety standards.

What Specialized Expertise Should You Look For?

Performance wear manufacturing requires distinct skills that go beyond basic apparel production. The right partner should demonstrate comprehensive understanding of technical requirements and children-specific considerations.

Specialized expertise ensures your manufacturer can navigate the complexities of performance wear while maintaining appropriate safety standards for children.

Why is Technical Fabric Knowledge Crucial?

Performance wear depends heavily on advanced fabric technologies. Your manufacturer should have deep knowledge of performance fabrics including moisture-wicking materials, temperature regulation technologies, UV protection treatments, and durable water repellent (DWR) coatings. They should understand how these fabrics behave during children's active use and how to test for performance claims. At our factory, we maintain an extensive library of technical fabrics specifically tested for children's wear applications, ensuring we can recommend materials that balance performance with comfort and safety.

What Construction Techniques Matter Most?

Performance wear requires specialized construction that withstands active use while maintaining comfort. Look for manufacturers experienced with flatlock stitching for chafe-free seams, reinforced stress points for durability, and strategic ventilation for temperature management. The manufacturer should understand how to balance technical requirements with children's sensitivity needs, using softer elastics, tagless labeling, and ergonomic patterning that accommodates active movement without restriction.

| Expertise Area | Performance Requirement | Children-Specific Consideration | Verification Method |

|---|---|---|---|

| Fabric Technology | Moisture management, durability | Softness, non-toxic treatments | Technical data sheets, safety certifications |

| Construction | Reinforced seams, mobility | Chafe prevention, comfort | Sample evaluation, wear testing |

| Safety Compliance | Performance standards | Children's product regulations | Certification review, testing protocols |

| Pattern Making | Athletic fit, movement | Growth accommodation, proportions | Fit session observation, size chart analysis |

How to Verify Manufacturing Capabilities?

Verifying a manufacturer's actual capabilities goes beyond reviewing their marketing materials. Comprehensive due diligence ensures they can deliver on their promises and meet your specific performance wear requirements.

Thorough verification prevents costly mistakes and ensures your manufacturer can scale with your business growth.

What Factory Audit Questions Should You Ask?

During factory visits, ask specific questions about their performance wear experience and capabilities. Inquire about their current clients in performance categories, their equipment for handling technical fabrics, and their quality control processes for performance features. Ask to see examples of similar projects and discuss their approach to problem-solving when technical challenges arise. The most revealing answers often come from asking about their biggest learning experiences and how they've improved their processes based on past challenges.

How to Assess Technical Capability?

Technical assessment should include evaluation of their testing facilities and quality assurance protocols. Check if they have in-house capability for basic performance testing or partnerships with certified laboratories. Review their documentation systems for tracking fabric lots and production batches. Assess their pattern-making expertise for performance fit and their sample development process for incorporating technical feedback. Manufacturers with strong technical capabilities will welcome these questions and demonstrate organized systems for maintaining quality consistency.

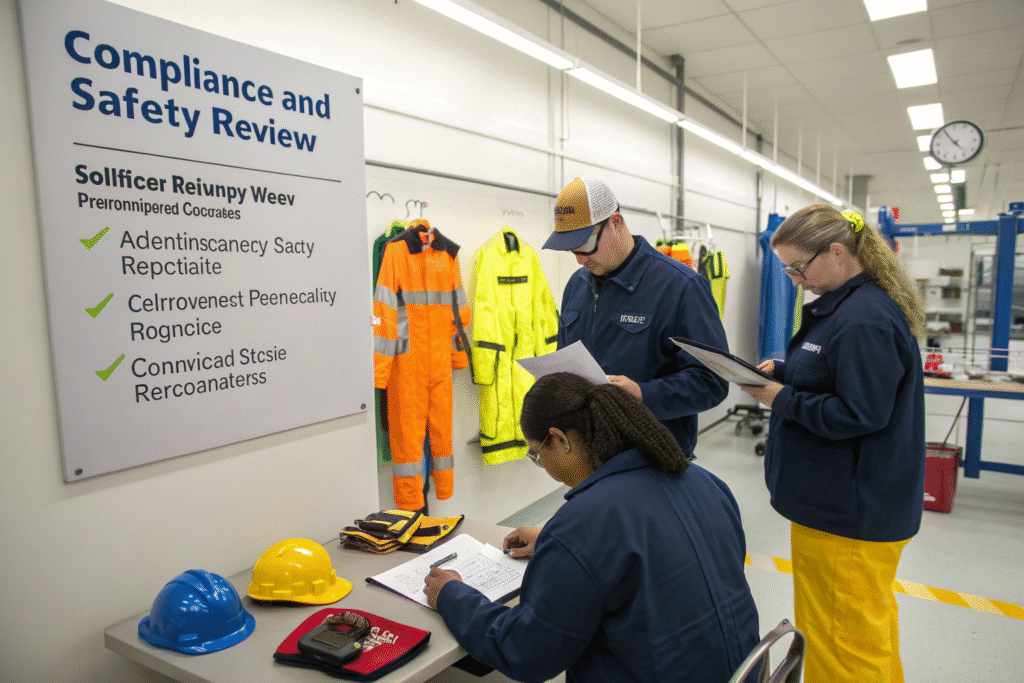

What Safety and Compliance Factors Are Critical?

Children's performance wear must meet rigorous safety standards while delivering technical performance. The manufacturer's understanding of and commitment to compliance directly impacts your product's marketability and liability exposure.

Safety compliance cannot be compromised, even when pursuing advanced performance features.

What Certifications Should You Require?

Essential certifications for children's performance wear include CPSC compliance for US markets, OEKO-TEX Standard 100 for chemical safety, and specific performance certifications relevant to your claims (such as UV protection standards or moisture management verification). The manufacturer should maintain current certifications and have systems for regularly updating compliance as standards evolve. They should also understand regional variations in safety requirements if you plan to sell in multiple markets.

How to Verify Quality Consistency?

Consistent quality requires robust systems and disciplined execution. Evaluate their quality management processes through document review and production observation. Check how they handle non-conforming materials, their inspection frequency during production, and their final quality control procedures. Ask about their track record for on-time delivery and quality consistency across production runs. Manufacturers with strong quality systems will have clear documentation, trained quality staff, and measurable quality metrics they regularly review and improve.

How to Evaluate Communication and Partnership Potential?

The manufacturer relationship extends beyond transactional production to strategic partnership. Effective communication and cultural alignment significantly impact project success, especially when developing technically complex products.

The right partnership approach can transform manufacturing from a cost center to a competitive advantage.

What Communication Systems Support Success?

Look for manufacturers with established communication protocols including regular progress updates, clear escalation paths for issues, and designated contacts for different concern types. They should provide transparent access to production status and promptly communicate any challenges. The best partners offer multiple communication channels while maintaining consistency in messaging and documentation. At our facility, we assign dedicated project managers who serve as single points of contact while facilitating access to technical experts as needed.

How to Assess Cultural Alignment?

Cultural alignment affects everything from problem-solving approaches to quality standards. Evaluate whether the manufacturer shares your values around transparency, innovation, and quality commitment. Discuss how they've handled past challenges with other clients and observe how they approach difficult conversations during negotiations. Manufacturers who view themselves as partners rather than vendors will demonstrate investment in your success through proactive suggestions, honest assessments, and willingness to accommodate reasonable special requests.

Conclusion

Finding the right manufacturer for children's performance wear requires thorough investigation of technical capabilities, safety compliance, quality systems, and partnership potential. The ideal partner combines performance wear expertise with children's product specialization, maintaining rigorous standards while offering collaborative problem-solving approach. This comprehensive evaluation process, while time-consuming, ensures a manufacturing relationship that supports your brand's growth and reputation for quality.

At Shanghai Fumao Clothing, we've specialized in children's performance wear manufacturing because we understand the unique intersection of technical requirements and children's needs. Our expertise in technical fabrics, performance construction, and children's safety standards makes us an ideal partner for brands seeking to create high-performance children's apparel. If you're looking for a manufacturing partner with proven performance wear capabilities, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's discuss how we can bring your performance wear vision to life with technical excellence and safety assurance.