Finding the right manufacturing partner for custom school uniforms presents significant challenges for brands and distributors. The process requires identifying suppliers who can balance quality standards with commercial viability while maintaining consistent delivery performance.

Successful manufacturer selection hinges on three critical factors: documented expertise in youth apparel manufacturing, established quality assurance protocols, and proven supply chain reliability. Partnering with factories with specific experience in educational wear ensures compliance with safety regulations and durability requirements.

This analysis examines the key considerations for identifying manufacturing partners capable of meeting the specialized demands of the school uniform sector.

What Technical Capabilities Differentiate Quality Uniform Manufacturers?

Manufacturing partners must demonstrate capabilities beyond basic garment production. Their technical infrastructure directly impacts product consistency and compliance.

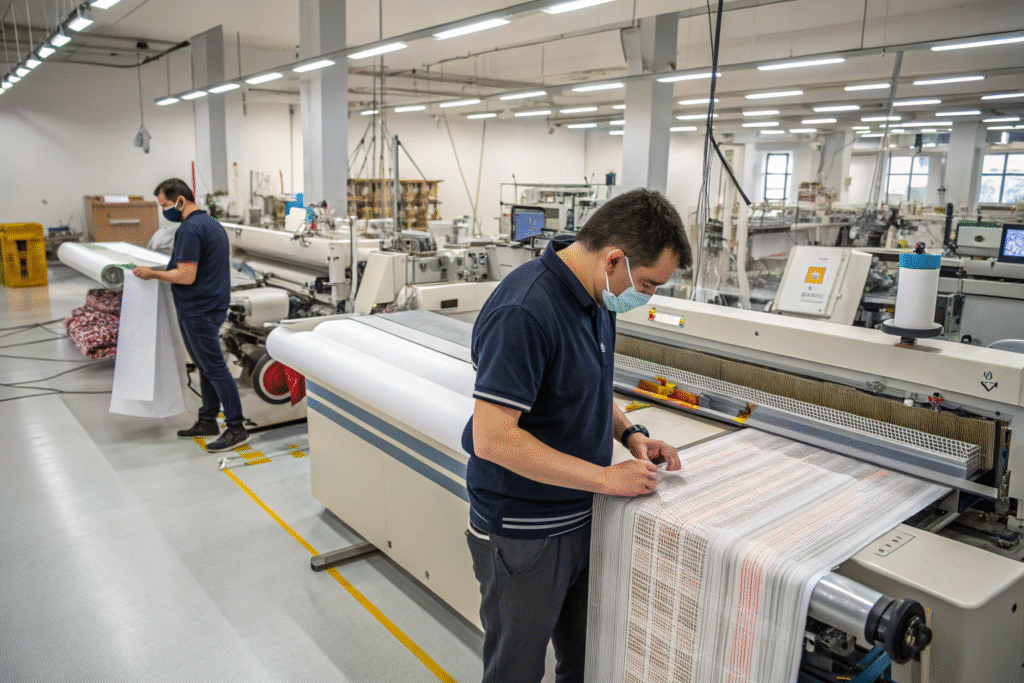

Superior manufacturers possess specialized equipment for woven garments, established fabric testing protocols, and technical design teams experienced in youth sizing specifications. These elements ensure dimensional stability and consistent fit across production runs.

How does specialized machinery impact uniform quality?

Dedicated equipment for woven fabric construction is essential for achieving the precise stitching and seam strength required in school uniforms. Manufacturers utilizing industrial-grade interlock stitch machines and bar tack reinforcements produce garments that withstand rigorous daily use. At Fumao Clothing, our production lines are configured specifically for technical apparel manufacturing, ensuring consistent tension control and stitch density across all units. This specialized approach minimizes production variances and enhances garment durability.

What compliance documentation verifies manufacturing standards?

Comprehensive documentation provides objective evidence of manufacturing capabilities. Reputable suppliers maintain current ISO 9001 certification for quality management systems and specific product certifications like OEKO-TEX Standard 100 for textile safety. Additionally, manufacturers should provide material test reports verifying fabric composition, colorfastness, and shrinkage properties. These documents demonstrate adherence to international standards and provide assurance of product safety and performance characteristics.

What Sourcing Channels Yield Qualified Manufacturing Partners?

Strategic sourcing methodology significantly impacts partner identification efficiency. Different channels offer varying levels of supplier verification and engagement depth.

Effective sourcing combines digital platform utilization with industry networking and direct engagement at trade events. This multi-channel approach provides both breadth of options and depth of verification.

How effective are B2B platforms for identifying technical partners?

Digital marketplaces provide extensive supplier databases but require careful filtering to identify technically capable partners. Platforms like Alibaba offer verification badges indicating supplier status, but additional due diligence is essential. Key assessment criteria include factory audit reports, production capacity documentation, and client references specifically from the educational apparel sector. Verified suppliers with extensive product portfolios and transparent communication channels typically demonstrate higher capability levels.

What value do industry events provide in partner evaluation?

Major trade shows like ISPO and sector-specific exhibitions enable direct assessment of manufacturing capabilities. These events facilitate technical discussions, sample evaluation, and face-to-face meetings with production management. The opportunity to examine construction techniques, fabric handfeel, and finishing details provides critical insights beyond digital representations. Additionally, these engagements allow for preliminary assessment of communication effectiveness and technical responsiveness.

How Should Manufacturers Be Evaluated for Technical Compliance?

Systematic evaluation processes are essential for verifying manufacturer claims and ensuring alignment with product requirements. Assessment should cover both technical capabilities and operational reliability.

Comprehensive evaluation incorporates facility audits, sample testing, and supply chain verification. This multi-faceted approach provides a complete picture of manufacturing readiness and compliance.

| Assessment Category | Verification Methods |

|---|---|

| Production Capability | Facility audit reports, equipment inventory, staffing structure |

| Quality Systems | Inspection protocols, testing equipment, non-conformance processes |

| Supply Chain Management | Raw material traceability, subcontractor management, inventory systems |

| Regulatory Compliance | Certification validity, testing reports, compliance documentation |

What specific quality metrics should be evaluated?

Manufacturers should provide definitive data points including first-pass yield rates, product defect percentages, and return rates from previous orders. Additionally, they should demonstrate statistical process control implementation in critical production stages. These metrics indicate the maturity of their quality systems and predict consistency in large-volume production. Factories with established measurement and analysis protocols typically demonstrate higher product consistency and fewer quality excursions.

How should production capacity be verified?

Capacity verification should extend beyond simple machine counts to include detailed analysis of production line configurations, workforce allocation, and current capacity utilization. Manufacturers should provide evidence of their ability to handle projected order volumes without quality degradation, including details about their production planning systems and lead time management. This analysis ensures they possess both the physical resources and management systems to meet delivery commitments while maintaining quality standards.

What Quality Assurance Protocols Ensure Product Consistency?

Robust quality management requires systematic implementation of verification activities throughout the production process. These protocols must address both product characteristics and production processes.

Effective quality systems incorporate predefined specifications, in-process monitoring, and final inspection protocols. This layered approach identifies issues early and prevents defect propagation.

How do technical packages facilitate quality management?

Comprehensive technical packages serve as the foundation for quality management by providing explicit, measurable specifications for all product characteristics. Effective tech packs include graded measurement specs, tolerance ranges, construction details, and approved fabric and trim references. These documents eliminate interpretation variances and provide objective criteria for quality verification at each production stage. Detailed tech packs enable manufacturers to identify potential production challenges during pre-production planning.

What inspection methodologies verify final product quality?

Statistically based sampling plans provide reliable quality verification while maintaining inspection efficiency. The AQL (Acceptable Quality Level) standard defines sample sizes and acceptance criteria based on order quantity and risk classification. Professional inspection teams verify product dimensions, workmanship, function, and packaging against established criteria. This methodology provides consistent, data-driven acceptance decisions and identifies systematic quality issues requiring corrective action.

Conclusion

Identifying appropriate manufacturing partners for custom school uniforms requires systematic evaluation of technical capabilities, quality systems, and operational reliability. The selection process should prioritize documented expertise in youth apparel manufacturing and verified quality management systems.

For organizations seeking manufacturing partnerships with demonstrated capabilities in educational apparel, we invite technical discussions regarding your specific requirements. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to initiate capability reviews and project planning.