Designing children's clothing for American middle-class families requires strategic planning. These consumers seek value above all. They want quality clothing that withstands active use. They also need affordable prices. The challenge lies in balancing these competing demands.

Successful designs must prioritize three elements: durable construction, safety compliance, and timeless styling. These features ensure clothing lasts through multiple children and washing cycles while maintaining appearance and integrity.

Understanding these core requirements helps brands create products that truly resonate with this market segment.

What Are The Key Design Elements For American Middle-Class Kids' Wear?

American middle-class parents prioritize practical considerations. They need clothing that serves multiple purposes. Garments must withstand rough play and frequent washing. Parents also value mix-and-match versatility.

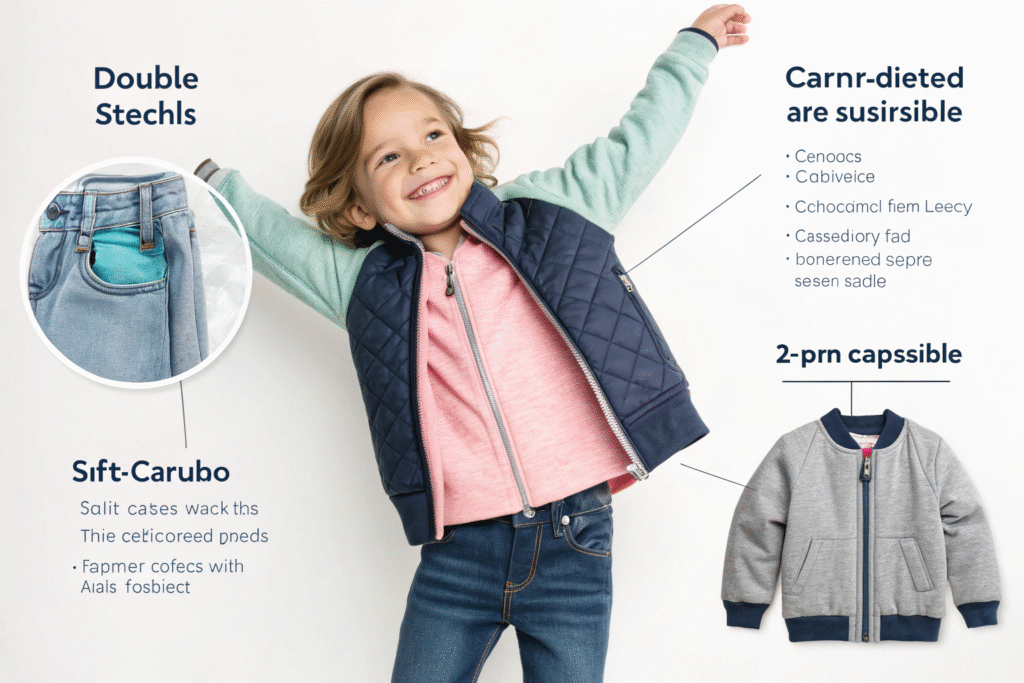

Key design elements include reinforced stitching, quality fabric selection, and coordinated color palettes. These features extend garment lifespan and increase wardrobe flexibility, providing better value for money.

These practical design choices directly address the financial considerations of middle-class families.

How Can Durability Be Incorporated Into Design?

Durability begins with fabric selection. Choose sturdy cotton blends that resist pilling. Reinforce high-stress areas with bar-tacking. Use double-stitched seams for extra strength. Select durable zippers and closures. Darker colors hide stains effectively. These features ensure clothing survives multiple children.

Why Is Versatile Styling So Important?

Versatile styling maximizes wardrobe utility. Coordinated color schemes allow easy mixing. Simple designs transition between occasions seamlessly. Unisex styles suit siblings of either gender. This approach reduces clothing costs per wear. Families appreciate this economic advantage.

How To Balance Cost And Quality In Children's Clothing?

Cost-quality balance presents a significant challenge. Parents want premium materials and construction. They also need reasonable prices. Achieving this balance requires strategic manufacturing decisions.

Manufacturers balance cost and quality through efficient production methods. They source materials in bulk for better pricing. They simplify designs to reduce waste. These strategies maintain quality while controlling costs.

This approach delivers the value that middle-class families expect.

What Sourcing Strategies Control Costs?

Strategic sourcing reduces expenses. Manufacturers establish relationships with fabric mills. They use standardized components instead of custom parts. They consolidate production runs for efficiency. These methods lower material and manufacturing costs significantly.

How Does Design Impact The Final Price?

Design complexity affects pricing directly. Simple designs with fewer colors cost less to produce. Efficient pattern cutting reduces fabric waste. Standardized sizing simplifies manufacturing. These design choices make quality clothing more affordable.

What Safety Standards Must US Kids' Apparel Meet?

Safety compliance is non-negotiable for children's clothing. American regulations are strict and comprehensive. Manufacturers must understand all requirements thoroughly.

All children's apparel must meet CPSIA standards. These regulations cover lead content, phthalate limits, and flammability requirements. Proper testing and certification are mandatory for market access.

Compliance ensures child safety and legal protection for brands.

Why Is CPSIA Compliance Critical?

CPSIA compliance prevents legal issues. It requires third-party testing by accredited labs. Manufacturers must provide Children's Product Certificates. These documents prove regulatory compliance. Proper documentation prevents customs delays.

How Do Flammability And Small Parts Rules Protect Children?

Flammability standards prevent burn injuries. Sleepwear requires special attention. Small parts regulations address choking hazards. Buttons and snaps must pass pull tests. These protections are especially crucial for young children.

How To Source A Reliable Kids' Wear Manufacturer?

Choosing the right manufacturer is crucial for success. The partner must understand your quality standards and business needs. They must also comply with all regulatory requirements.

Select manufacturers with proven experience in your target market. Verify their certifications and inspect their facilities. Check references from current clients. Ensure they have robust quality control systems.

Thorough vetting prevents future problems and ensures consistent quality.

What Are The Red Flags In A Manufacturer?

Several warning signs indicate unreliable partners. Refusal to provide factory tours suggests hidden problems. Vague answers about compliance processes raise concerns. Unrealistically low prices often mean compromised quality. Poor communication predicts future difficulties.

Why Is A Factory's Communication Style Important?

Clear communication ensures project success. Dedicated account managers prevent misunderstandings. Regular updates keep projects on schedule. Fluent English speakers avoid translation errors. Proactive problem-solving prevents major issues.

Conclusion

Designing for the American middle-class market requires careful strategy. Manufacturers must balance cost and quality effectively. They must ensure full regulatory compliance. They must also maintain clear communication with partners.

These elements combine to create successful children's clothing lines that meet market demands.

We invite you to experience our manufacturing capabilities. Shanghai Fumao Clothing specializes in American market children's wear. Our team ensures quality, compliance, and timely delivery. Contact Business Director Elaine at elaine@fumaoclothing.com to discuss your production needs.