As a factory owner, I see it all the time: a brand comes to us with a fantastic design for kids' activewear, but the fabric choice makes or breaks the final product. They want something soft, durable, breathable, quick-drying, affordable, and sustainable—often all at once. The truth is, no single fiber is a magic bullet. The secret to high-performance kids' activewear lies in the blend. Choosing the right fabric blend is a strategic decision that balances performance, comfort, durability, and cost. It’s the difference between a garment that gets worn once and forgotten, and one that becomes a go-to favorite for park runs, soccer practice, and weekend adventures.

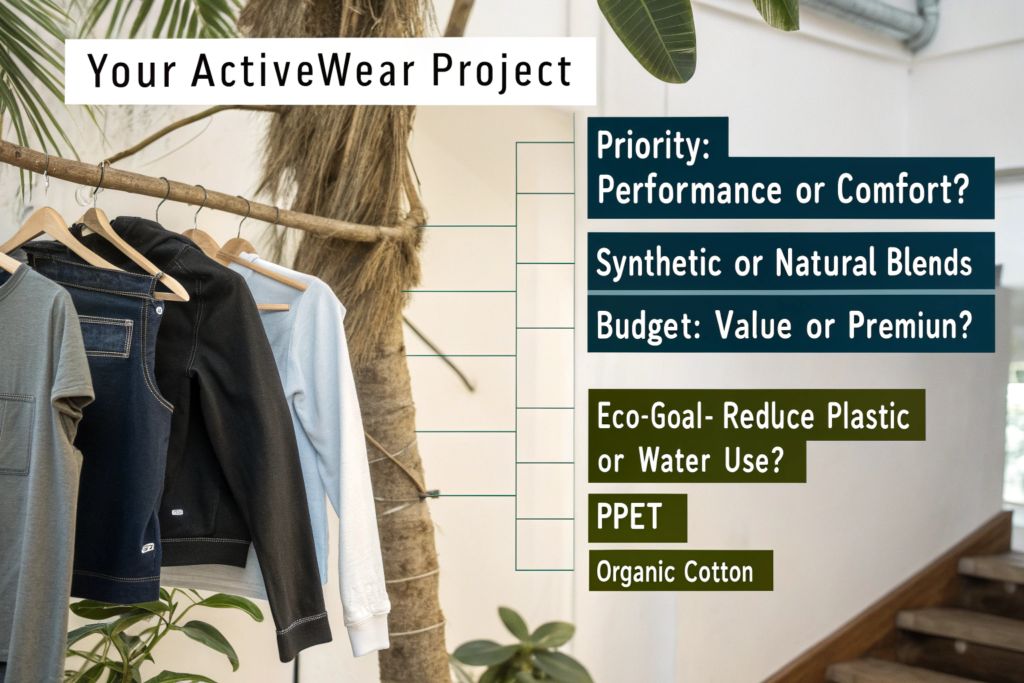

Choosing between different fabric blends for kids' activewear requires analyzing the specific performance needs of the activity, prioritizing key properties like moisture management, breathability, durability, and softness, and understanding the cost and sustainability trade-offs of combining natural fibers (like cotton) with synthetic fibers (like polyester) or other advanced materials.

Think of it as a recipe. You wouldn't use the same ingredients for a cake and a loaf of bread. Similarly, the ideal blend for yoga pants differs from that for a running jacket. The goal is to combine fibers so that the strengths of one compensate for the weaknesses of another, creating a synergistic fabric that outperforms any single component. Let's break down the decision-making framework to help you select the perfect blend for your collection.

1. What Are the Core Performance Needs for Kids' Activewear?

Before you look at any fabric swatch, define what the garment needs to do. Kids' activewear isn't just casual clothing; it's performance gear for small, energetic bodies. The core requirements are universal but weighted differently based on the activity.

The non-negotiable pillars are: Moisture-Wicking, Breathability, Durability, and Comfort (Softness & Stretch). Moisture-wicking is the fabric's ability to pull sweat away from the skin to the outer surface where it can evaporate. This keeps the child dry and prevents chills. Breathability allows heat and vapor to escape, preventing overheating. Durability means the fabric can withstand abrasion from slides, grass, and repeated washing without pilling, tearing, or fading. Comfort encompasses both a soft hand-feel against sensitive skin and adequate mechanical stretch (often from elastane like Lycra or Spandex) for unrestricted movement. A failure in any of these areas leads to an unhappy child and a dissatisfied parent.

How Does Activity Type Dictate Fabric Priority?

The "job" of the garment defines the priority of these needs.

- High-Intensity & Team Sports (Soccer, Running): Moisture-wicking and breathability are paramount. These activities generate a lot of sweat and heat. Fabrics must dry extremely quickly to prevent clamminess and chafing. Durability for falls and stretches is also critical.

- Low-Impact & Flexibility (Yoga, Dance): Stretch and comfort are king. The fabric needs to move with the body, offer four-way stretch, and feel incredibly soft against the skin. Breathability is still important, but moisture-wicking pressure is slightly lower.

- Outdoor Adventure (Hiking, Climbing): Durability and breathability lead. These garments face abrasion from rocks, branches, and backpacks. They also need to handle variable temperatures, so breathability and some thermal regulation are key.

- Casual Active / Playwear: A balance of all properties is needed, often with a stronger emphasis on softness and a cotton-like feel for all-day comfort.

Why is Fit and Construction as Important as the Fabric?

The best fabric blend can be undermined by poor design. For activewear, the fit must be ergonomic—allowing for a full range of motion without bagging or riding up. Flatlock seams prevent chafing, and strategic mesh panels can enhance breathability in high-sweat zones. The fabric blend provides the raw material, but intelligent pattern-making and construction turn it into a high-performance garment.

2. Polyester Blends vs. Cotton Blends: What's the Real Difference?

This is the most fundamental choice in activewear. Polyester and cotton represent two different worlds of performance, and blending them creates a spectrum of possibilities.

Polyester-Dominant Blends (e.g., 90% Polyester / 10% Elastane) are the workhorses of high-performance activewear. Polyester is inherently hydrophobic (water-repelling), which makes it an exceptional moisture-wicker. It pulls sweat away from the skin rapidly and dries very fast. It's also highly durable, resistant to wrinkles and shrinkage, and holds color vibrantly. The downside can be a less natural, sometimes "plasticky" feel, and it can retain body odor if not treated. Adding a small percentage of elastane (like Lycra) provides the necessary stretch.

Cotton-Dominant Blends (e.g., 60% Cotton / 40% Polyester) prioritize comfort and softness. Cotton is natural, breathable, and feels luxurious against the skin. However, it is hydrophilic—it absorbs water and holds it. A 100% cotton t-shirt becomes heavy, soggy, and slow to dry during exercise, which can lead to discomfort and chilling. Blending cotton with polyester mitigates this weakness. The polyester helps wick moisture and improves durability and shape retention, while the cotton maintains a soft, familiar hand-feel. This blend is excellent for casual activewear, light exercise, or where supreme softness is the primary goal.

What About Advanced Polyester and Synthetic Blends?

Not all polyester is created equal. Recycled polyester (rPET) performs identically to virgin polyester but has a significantly lower environmental impact, making it a top choice for eco-conscious brands. Polypropylene is another synthetic known for being an exceptional moisture-wicker, often used in base layers. Nylon is frequently blended in for added strength and a silky feel, common in swimwear and leggings. When sourcing, ask your manufacturer about the availability and cost implications of these advanced synthetics.

How Does Tencel™ or Modal Change the Blend Game?

This is where innovation shines. Tencel™ (Lyocell) and Modal are regenerated cellulose fibers made from wood pulp. They offer a fantastic middle ground: the breathability and biodegradability of a natural fiber with moisture-wicking properties that rival synthetics. They are exceptionally soft, resist odor, and have a beautiful drape. A blend like 50% Tencel™ / 50% Organic Cotton creates a supremely soft, eco-friendly fabric perfect for lighter activewear or loungewear with performance benefits. While not as durable as polyester for intense abrasion, they represent the premium, sustainable end of the blend spectrum.

3. How to Evaluate Durability, Care, and Long-Term Value?

Parents invest in activewear expecting it to last through a season of growth and rough play. The chosen blend directly impacts the garment's lifespan and how easy it is to care for, which affects parent satisfaction and brand reputation.

Durability testing is key. Look beyond the initial hand-feel. Ask your manufacturer or fabric mill for data on pilling resistance (Martindale or pilling box test), colorfastness to washing and light, and tensile strength. Polyester and nylon score highly here. In blends, the synthetic component often provides the pill resistance, while the natural fiber contributes to comfort. Care instructions also matter. Blends with high synthetic content typically dry faster, resist wrinkles, and require less ironing—a practical benefit for busy families. A garment that looks faded, pilly, or misshapen after five washes is a failure, regardless of its initial performance.

What Are the Common Failure Points in Kids' Activewear?

Knowing where things go wrong helps you choose better. Common failures include:

- Pilling: Especially in areas of friction (underarms, inner thighs). Blends with a strong synthetic filament yarn (not short staple) are more resistant.

- Seam Failure: The fabric may be strong, but if the stitching thread isn't matched or the seam type is wrong, it will rip. This is a manufacturing execution issue.

- Color Fading: Especially with cheap dyes on polyester. Ensure your manufacturer uses high-quality, colorfast dyes.

- Loss of Elasticity: Over time, the elastane component can degrade, especially with exposure to high heat (dryers, hot washes). Blends with a lower percentage of quality elastane and proper care labeling can mitigate this.

How Does Fabric Weight and Construction Impact Durability?

The weight of the fabric, measured in GSM (grams per square meter), matters. A 180 GSM polyester blend might be perfect for a summer running tee, but a 300 GSM French terry cotton blend would be better for durable sweats or hoodies. The construction also matters—a tight, smooth knit will be more abrasion-resistant than a loose, brushed one. Discuss the intended use with your manufacturer to get their recommendation on the optimal GSM and knit structure for your design.

4. What Are the Sustainability and Cost Trade-Offs?

Finally, the decision comes down to budget and values. Every fiber choice has an environmental footprint and a price tag. The "best" blend aligns with your brand's positioning and your customer's willingness to pay.

The Cost Spectrum: Generally, basic polyester blends are the most cost-effective. Cotton blends are slightly more expensive. Blends featuring organic cotton, recycled polyester (rPET), or Tencel™ command a premium due to more costly raw materials and processes. The Sustainability Spectrum: Conventional polyester is derived from petroleum but is durable and recyclable. rPET is a better choice, turning plastic waste into fabric. Conventional cotton is water and pesticide-intensive; organic cotton is a major improvement. Tencel™ is celebrated for its closed-loop, eco-friendly production process. There is no perfect answer, only a series of trade-offs. A blend of rPET and organic cotton can be an excellent balance of performance, eco-credentials, and manageable cost.

How Can a Manufacturer Help Navigate These Choices?

This is where a knowledgeable partner is invaluable. A good manufacturer won't just give you a price list; they will act as a consultant. At Fumao, we help our clients by:

- Providing Physical Swatches: Feel and compare the drape, weight, and softness.

- Sharing Test Data: Showing pilling, shrinkage, and colorfastness reports for different blends.

- Offering Tiered Options: Presenting a good-better-best selection based on performance and cost (e.g., standard polyester, rPET, rPET/Tencel™ blend).

- Clarifying Lead Times: Some specialty or certified fabrics have longer sourcing lead times.

Why is Prototyping with the Final Blend Essential?

Never finalize a design based on a similar fabric. Always make a production prototype with the exact blend, weight, and construction you intend to use. Put it through real-world testing: have a child wear it, wash it multiple times, and stretch it. Does it recover its shape? Does it feel comfortable during activity? Does it look good after washing? This step de-risks your entire order and ensures the final product lives up to the promise of your chosen blend.

Conclusion

Choosing the right fabric blend for kids' activewear is a critical, multi-faceted decision that sits at the intersection of science, ethics, and commerce. It requires you to define the garment's performance mission, understand the functional dialogue between fibers, demand proof of durability, and make informed trade-offs between cost and sustainability.

By approaching this process strategically and in partnership with an experienced manufacturer, you can move beyond guesswork. You can confidently select blends that deliver on their promise—creating activewear that kids love to wear, parents appreciate for its quality and ease of care, and ultimately strengthens your brand's reputation for thoughtful, high-performance products.

Ready to engineer the perfect fabric blend for your next activewear line? Partner with a manufacturer who understands the recipe for success. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to collaborate with Shanghai Fumao on developing high-performance kids' activewear that stands up to play and wins in the market.