Choosing the right clothing manufacturer in China can feel like navigating a maze. One wrong turn and you're facing delayed shipments, quality issues, and lost profits. As the owner of Fumao Clothing, I've seen countless brands struggle with this decision. After decades in this business, I can tell you that the cheapest option often becomes the most expensive mistake. This guide will walk you through a practical, step-by-step framework to evaluate Chinese manufacturers, ensuring you find a partner that aligns with your brand's quality, ethical, and financial goals.

The best way to choose between clothing manufacturers in China is to conduct a multi-stage verification process that assesses their specialization, operational transparency, compliance track record, and communication efficiency. You must look beyond price and prioritize suppliers who offer clear evidence of quality control systems, valid certifications for your target market, and a proven history with brands of your size and type.

Many importers make the error of sourcing based on a single factor, like a low price per unit or a polished website. The most successful brands, however, use a disciplined approach. They define their non-negotiable requirements first, then systematically filter and audit potential partners. This process saves time and prevents the heartache of a failed production run.

How to Define Your Sourcing Requirements Clearly?

Before you even start searching, you must know exactly what you need. Vague requirements lead to mismatched partnerships and disappointing outcomes. Taking the time to document your specifications internally will make your conversations with potential suppliers infinitely more productive and efficient.

Start by defining your product category with precision. Are you producing heavyweight knitwear, technical outerwear, or delicate baby apparel? Each category requires different machinery and expertise. Next, be realistic about your order volume. A manufacturer that excels at 50,000-piece orders may be inefficient for a 2,000-piece startup run, and vice versa. Finally, establish your non-negotiable standards. This includes your acceptable quality control AQL levels, required safety certifications, and your maximum lead time.

What are the key questions to ask about product specialization?

You must ask manufacturers specifically about their experience with your product type. A factory might be excellent at men's polo shirts but lack the specialized equipment for baby clothes with intricate appliqué. Ask for a portfolio of similar items they have produced. At Fumao, we focus on kids' wear and knitted garments, so we can immediately show potential clients our collections for US brands. Inquire about their production lines. We have five dedicated lines, and one is specifically calibrated for smaller, more complex baby wear orders. This level of detail reveals true specialization.

How do you determine the right order volume for a new manufacturer?

Be upfront about your volume from the first conversation. Provide a clear forecast for your first order and the next 12 months. This allows the factory to tell you if you are a good fit. We categorize our clients into tiers: development batches (1,000-3,000 pieces), growth runs (5,000-20,000 pieces), and core partner programs (25,000+ pieces). This ensures we can allocate the right resources and production line for each brand. Matching your volume to a factory's sweet spot is crucial for receiving the attention and priority you deserve.

What is the Most Effective Supplier Verification Process?

Once you have a shortlist of potential manufacturers, you must move from promises to proof. A rigorous verification process separates marketing claims from operational reality. This stage is your primary defense against fraud, delays, and quality failures.

The first step is to verify business legitimacy. Use official Chinese platforms like the National Enterprise Credit Information Publicity System to confirm their business registration, legal representative, and registered capital. Next, scrutinize their compliance certifications. For the US market, this includes CPSIA compliance for children's products. Do not accept a certificate at face value; ask for the test report from an accredited lab and verify its authenticity online. Finally, the most critical step is the factory audit. This can be done in-person or via a live video tour.

How can you verify a manufacturer's quality claims?

Request a detailed Quality Control Process document. A professional manufacturer will have this. It should outline their in-process checks, final inspection protocols, and the AQL standard they follow. Ask for evidence. We provide our clients with sample QC reports from past orders, with client names redacted. This shows exactly how we document and track defects. You can also order a pre-production sample from their actual production line, not a sample room. This tests their ability to replicate your design in bulk.

What should you look for during a factory audit?

An audit checks for operational health. Look for organization on the factory floor. Are fabrics stored neatly? Is there a clear separation between cutting, sewing, and packing areas? Observe the machinery. Modern, well-maintained equipment is a sign of a professional operation. Check the social compliance aspect. Are workers equipped with proper safety gear? We open our doors to audits because a clean, efficient, and ethical factory is our best asset. An audit is the only way to confirm that the factory you see online is the one that will produce your clothes.

How to Evaluate Communication and Service Support?

Inefficient communication is one of the top pain points for importers. The time zone difference and language barrier can become major obstacles. How a manufacturer communicates before you place an order is a strong indicator of what will happen after you pay the deposit.

Evaluate response times and the quality of answers. Do they answer your specific questions directly, or do they send vague, generic replies? Identify your main point of contact. Is it a salesperson who just takes orders, or a dedicated project manager who understands production details? At Fumao, we assign a Project Manager to each client. This person speaks fluent English and has the technical knowledge to discuss your tech pack, sampling process, and production schedule without needing to constantly "check with the factory."

What are the signs of a proactive service partner?

A proactive partner anticipates problems. They will ask detailed questions about your tech pack to clarify ambiguities before production. They will advise on fabric choices based on durability and cost for your market. They provide regular, unsolicited updates instead of waiting for you to chase them. After a recent fabric price shift, we immediately informed all our affected clients and provided alternative material options, helping them maintain their margins. This level of service is what separates a true partner from a mere order-taker.

How does a manufacturer's sampling process reflect their capabilities?

The sampling process is a microcosm of the entire production run. A professional factory will have a clear, staged sampling process: proto sample, fit sample, and pre-production sample. Each stage has a purpose and requires your approval before moving forward. Note the speed and accuracy of their sample creation. If a factory cannot get a sample right after two iterations, it is a major red flag for bulk production. We document all sample feedback in a shared tracking sheet, ensuring complete alignment and a clear audit trail.

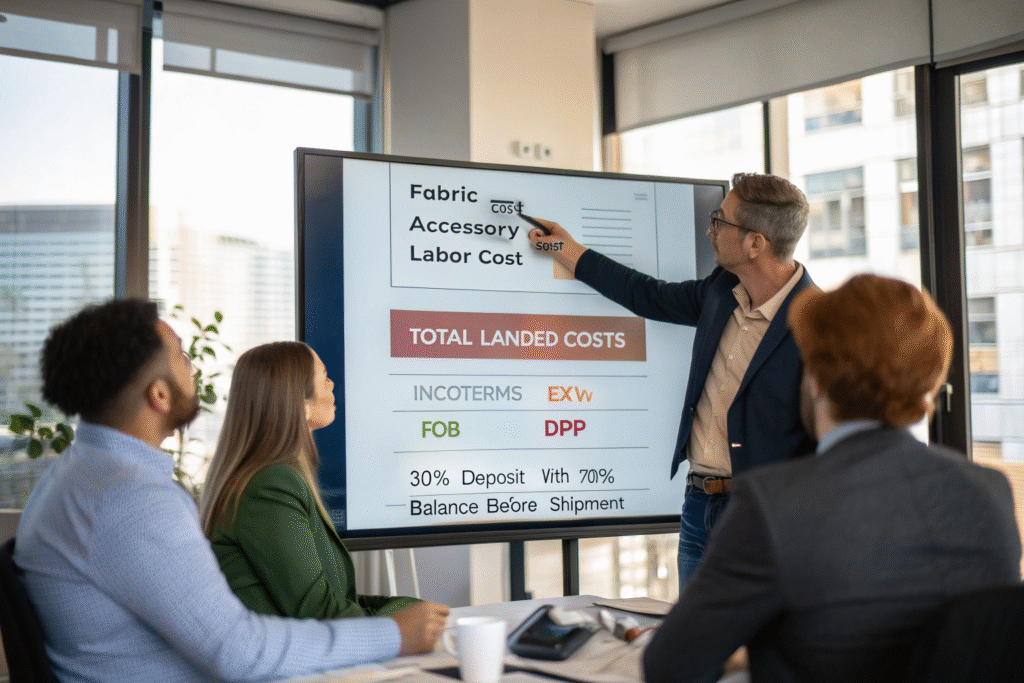

How to Compare Pricing and Logistics Terms Accurately?

Price comparison is more than just looking at the cost per garment. You must compare the total landed cost and understand the financial terms that protect your investment. A low FOB price can be misleading if it hides high logistics costs or risky payment terms.

Always request a detailed cost breakdown. This should include fabric cost, accessory cost, labor cost, and profit margin. Transparency here builds trust. Then, clarify the Incoterms. Are they quoting EXW, FOB, or DDP? A DDP price includes all costs to your warehouse, providing ultimate predictability. We find that many of our US clients now prefer DDP because it simplifies their logistics and budgeting. Finally, analyze the payment terms. Standard terms are 30% deposit with 70% balance before shipment. Be wary of suppliers demanding 50% or more upfront.

What hidden costs should you look for in a quotation?

Common hidden costs include charges for specific packaging (like custom polybags), testing fees for compliance, and sampling fees. A reputable supplier will list these potential add-ons upfront. Our quotations have a clear section for "Standard Inclusions" and "Optional/Premium Services," so there are no surprises. Another hidden cost is the price of modifications. Confirm if there are costs for adjusting a tech pack after production has started.

Why are logistics terms critical for your bottom line?

The chosen Incoterm determines your risk and responsibility. Under FOB, you are responsible for the main freight and insurance, costs which have been highly volatile. Under EXW, you are responsible for everything from the factory gate onward. DDP mode offers the simplest and most predictable cost structure for the importer. We provide a side-by-side cost comparison for our clients, showing the FOB price versus the all-in DDP price, so they can make a fully informed financial decision.

Conclusion

Choosing the right clothing manufacturer in China is a strategic decision that goes far beyond unit price. It requires a disciplined approach to verify specialization, operational integrity, communication quality, and total cost. By prioritizing partners who offer transparency, proven expertise, and a collaborative service model, you can build a supply chain that is not only cost-effective but also resilient and reliable.

Your brand deserves a manufacturing partner that acts as an extension of your team. If you are looking for a specialized kids' wear manufacturer with a transparent process, verifiable certifications, and a commitment to seamless communication, we are here to help. Contact our Business Director, Elaine, to start a data-driven conversation about your needs. Reach her directly at elaine@fumaoclothing.com.