Ensuring ethical production in children's wear factories is a profound responsibility that extends far beyond compliance checkboxes. It's about guaranteeing that the garments bringing joy to children are not born from the exploitation of other people's children, parents, or communities. As a manufacturer committed to this principle, I can attest that ethical production is a continuous, proactive discipline—a system of verified practices, transparent relationships, and unwavering values that must be engineered into the supply chain from the ground up.

You can ensure ethical production in children's wear factories by conducting rigorous, unannounced third-party social audits, building long-term partnerships based on transparency and fair pricing, implementing traceable supply chains with certified materials, empowering workers through direct engagement and grievance mechanisms, and going beyond audits to invest in community and environmental well-being.

This is not a passive process of receiving certificates; it is an active, ongoing partnership of verification and improvement. Let's outline the concrete steps and mindset required to turn ethical intent into verified reality.

What Are the Foundational Steps for Vetting and Auditing?

The first step is due diligence. You cannot ensure what you do not measure. This requires moving beyond a factory's self-assessment to independent, verified evaluation using globally recognized standards.

This involves pre-qualifying factories with a detailed questionnaire on policies, then commissioning unannounced audits by accredited third-party firms against standards like SA8000, WRAP (Worldwide Responsible Accredited Production), or the Sedex Members Ethical Trade Audit (SMETA). These audits examine working hours, wages, health & safety, freedom of association, and prohibitions on child/forced labor. Crucially, you must review the full audit report, not just a certificate, paying close attention to corrective action plans (CAPs) for any non-conformities.

Why are Unannounced Audits and Worker Interviews Critical?

Announced audits allow for "window dressing." Unannounced audits provide a more realistic snapshot of daily conditions. Even more important is the confidential worker interview process, conducted off-site or in private by auditors who speak the workers' language. This is where you uncover the truth about overtime coercion, wage violations, or harassment that may not be visible on paperwork. A factory that is transparent and confident in its practices will welcome unannounced audits and facilitate worker interviews without interference.

How to Interpret Audit Reports and Corrective Action Plans?

An audit with zero findings is rare and sometimes suspect. The mark of an ethical factory is not perfection, but transparency and commitment to correction. When you receive an audit report:

- Review All Findings: Major vs. minor non-conformities.

- Analyze the CAP: Does the factory's proposed corrective action address the root cause? Is the timeline realistic?

- Verify Closure: Follow up to receive evidence that the CAP has been completed (e.g., photos of new safety guards, updated payroll records).

- Make it a Partnership: Offer to share the cost of necessary improvements (e.g., installing better ventilation). This shows you are a partner, not just a policeman.

Resources like the Fair Labor Association (FLA) provide frameworks for this ongoing improvement process.

How Does Building a Transparent and Fair Partnership Enable Ethics?

Ethical production cannot be sustained through audit pressure alone. It requires a business relationship that makes ethical behavior economically viable for the factory. This means moving from a transactional, price-squeezing dynamic to a strategic partnership based on fair pricing, predictable orders, and long-term commitment.

This involves paying a price that allows for living wages, providing reasonable lead times to prevent mandatory excessive overtime, offering multi-season contracts to provide job security for workers, and being transparent about your own margins and challenges. A factory fighting for survival on razor-thin margins is far more likely to cut corners on labor and safety.

Why is "Fair Costing" the Bedrock of Ethical Manufacturing?

Pushing for the absolute lowest price directly contradicts ethical goals. To pay living wages, provide safe conditions, and fund environmental upgrades, a factory needs a fair profit margin. Engage in open cost breakdown discussions. Understand the costs of materials, labor, overhead, and a reasonable profit. Use living wage benchmarks from organizations like the Fair Wear Foundation or the Global Living Wage Coalition to ensure the labor cost in your quote is sufficient. Your purchasing practices must align with your ethical claims.

How Can Long-Term Contracts and Forecasts Promote Stability?

The fashion industry's volatility is a major driver of labor abuse. Factories facing last-minute, unpredictable orders resort to forced overtime to meet deadlines. You can combat this by:

- Providing Accurate Forecasts: Share your sales projections and planned production schedule as far in advance as possible.

- Signing Annual Agreements: Commit to a volume of business over a year, giving the factory confidence to invest in its workforce and facilities.

- Phasing Production: Spread orders out to avoid extreme peaks that demand unsustainable work hours.

This stability is a form of economic justice that allows factory owners to plan and workers to have predictable lives.

How to Implement Supply Chain Traceability and Material Ethics?

Ethics extend beyond the sewing floor to the fields where cotton is grown and the mills where fabric is dyed. A truly ethical children's wear brand must strive for transparency throughout its entire supply chain, ensuring raw materials are also sourced responsibly.

This requires mapping your supply chain to Tier 2 and Tier 3 (fabric mills, dye houses, trim suppliers) and sourcing certified raw materials like GOTS (Global Organic Textile Standard) certified cotton, which includes social criteria, or Fairtrade certified cotton. Technologies like blockchain and platforms like TextileGenesis are emerging to provide immutable proof of a material's journey from source to garment.

What Certifications Validate Material and Social Ethics?

Rely on respected, third-party certifications that cover both environmental and social aspects:

- GOTS (Global Organic Textile Standard): The gold standard. It certifies organic fiber status and includes stringent social criteria based on ILO conventions for every stage of processing.

- Fairtrade Textile Standard: Focuses on fair prices for farmers and safe conditions for workers, with a strong emphasis on living wages in production.

- OEKO-TEX Standard 100: While focused on chemical safety, it is a baseline indicator of a factory's commitment to responsible production practices.

Demand transaction certificates for these certifications specific to your order, not just a generic factory certificate.

Why is Chemical Management Part of Ethical Production?

The ethical duty of care extends to the health of workers and the end-wearing child. Dye houses and printing facilities can be hazardous if not properly managed. Ensure your factory partners have robust chemical management systems, use ZDHC (Zero Discharge of Hazardous Chemicals) compliant inputs, and treat wastewater. This protects local ecosystems and communities from pollution, fulfilling a broader environmental justice obligation.

How to Empower Workers and Foster Direct Engagement?

The most reliable indicator of an ethical factory is empowered, informed workers who can advocate for themselves without fear. Your due diligence should assess the mechanisms in place for worker voice and protection.

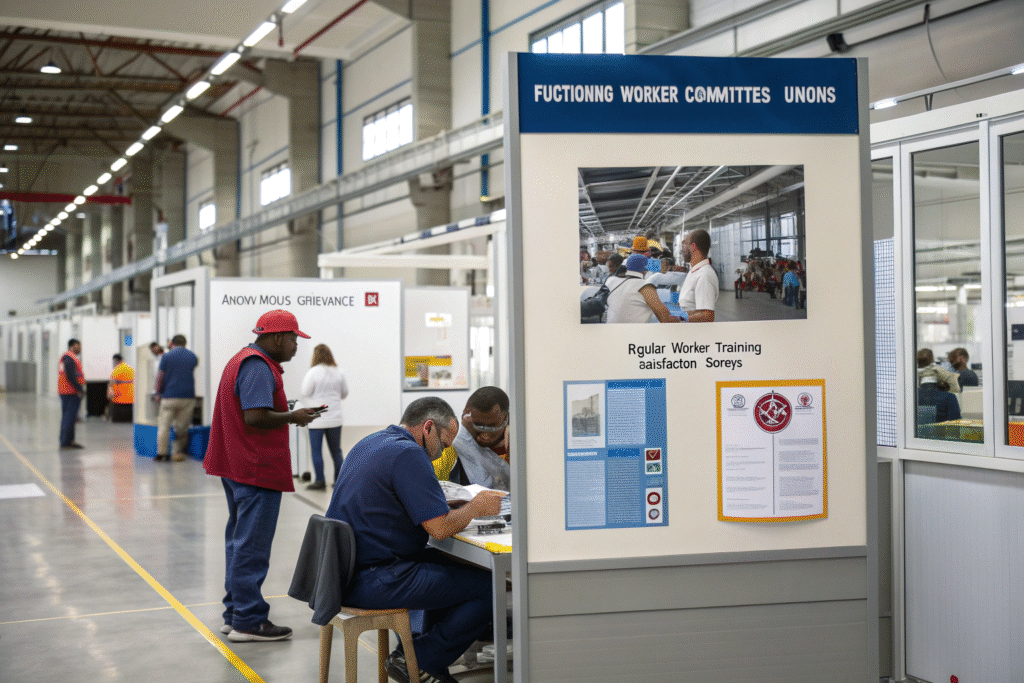

Look for evidence of functioning worker committees or unions, accessible and anonymous grievance mechanisms (like suggestion boxes or hotlines), regular worker training on their rights, and worker satisfaction surveys. Some of the most progressive brands facilitate direct, brand-worker dialogues (with interpreters) to hear concerns firsthand.

What Are Effective Worker Grievance Mechanisms?

A grievance mechanism is only effective if workers trust it. It should be:

- Accessible: Available in workers' native languages.

- Anonymous & Retaliation-Free: Workers must be assured that reporting an issue will not lead to punishment or job loss.

- Transparent: Workers should receive feedback on the status of their complaint.

- Effective: Issues should be resolved in a timely manner.

Ask the factory to walk you through their process and provide examples (with identities protected) of how grievances have been resolved.

How Can Brands Invest in Worker and Community Well-being?

Go beyond compliance to create positive impact. This could involve:

- Funding educational programs for workers or their children.

- Supporting healthcare initiatives for the factory community.

- Partnering on financial literacy or women's empowerment programs.

- Investing in factory improvements that benefit workers, like childcare facilities, better cafeteria food, or recreational spaces.

These investments build genuine goodwill, reduce turnover, and create a more skilled, loyal workforce—a win for everyone.

Conclusion

Ensuring ethical production in children's wear factories is a complex, layered, and relentless pursuit. It demands a shift from policing to partnership, from cost-cutting to value-building, and from opaque supply chains to radical transparency. It requires investing in rigorous verification, fair business practices, traceable materials, and empowered workers. While the path is challenging, it is the only path that aligns the innocence of the end product with the integrity of its creation.

For manufacturers who choose this path, like Fumao Clothing, it means building our entire operation around these principles—from our WRAP-certified facilities and GOTS-material sourcing to our open-book costing and worker engagement programs. We believe ethical production is not a constraint, but the foundation of superior quality and lasting partnership. If you are committed to building a brand with an unshakable ethical foundation, let's partner to make it a reality. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to begin a partnership built on integrity.