Children's skin is delicate—and so should be the fabrics they wear. That’s why not all satin is created equal when it comes to kidswear.

We customize children's-grade satin fabrics to be softer, stronger, and safer than commercial alternatives. Through fine yarn selection, hypoallergenic finishing, and anti-pilling engineering, our satin meets global safety and comfort standards for infant and kidswear.

When you’re creating dresses, skirts, linings, or costume apparel for children, satin may seem like the ideal choice. But standard satin often fails: it snags, pills, or irritates the skin. In this article, I’ll show you how Fumao develops customized satin specifically for children’s clothing—so your brand stands out with quality that parents trust.

Why Standard Satin Isn’t Enough for Kidswear

Off-the-shelf satin may look shiny—but it’s not always skin-safe.

Many commercial satins contain stiff fibers, chemical residues, or weak weaves that fail durability and comfort tests required for children's garments. Customized satin must go beyond aesthetics and meet rigorous quality benchmarks.

What problems arise from using unmodified satin for kids' clothes?

- Irritation: Standard polyester satin can feel scratchy or stiff due to thick filaments or resin finishes.

- Snagging: Loose weaves and long floats make satin vulnerable to pulls—especially in active children.

- Color Migration: Some dyes used in cheaper satin are not colorfast to saliva or sweat, causing safety concerns.

- Pilling: Low-quality yarns and soft finishes can lead to surface damage after a few wears or washes.

As a result, many large retailers require satin for kidswear to pass tests like:

- Oeko-Tex Standard 100 – Product Class I (for babies and toddlers)

- ASTM D4966 (abrasion resistance)

- AATCC 61 (colorfastness to laundering)

- ISO 14184-1 (formaldehyde content)

At Fumao, we pre-test every kidswear satin under these frameworks and offer lab reports upon request.

How We Customize the Yarn and Weave for Silkiness and Strength

Smooth doesn't mean weak. Our goal is softness and durability.

We engineer satin for children’s apparel using ultra-fine denier yarns, tightly woven satin constructions, and high-tenacity blends. This results in a silky, breathable, and resilient fabric ideal for both play and occasion wear.

What’s our yarn strategy for children’s-grade satin?

| Feature | Detail |

|---|---|

| Yarn Type | 75D/36F Micro-polyester or 50D/24F Recycled Filament |

| Cross-Section | Triangular or trilobal filaments for high luster |

| Yarn Source | GRS-certified spinners in Jiangsu & Zhejiang |

| Weave Structure | 5-harness or 8-harness satin weave for tighter body |

| Shrinkage Control | Pre-set with heat stabilization before dyeing |

Our 75D/36F satin has an optimal filament ratio to balance drape and durability. Compared to standard 100D/48F commercial satin, ours resists snagging 25–30% better and feels softer against the skin.

We also offer recycled polyester satin options with the same softness, helping sustainable kidswear brands meet both feel and eco goals.

Specialized Finishing for Hypoallergenic and Kid-Safe Use

No harmful finishes, no heavy chemicals—just clean, safe satin.

Children’s-grade satin from Fumao undergoes non-irritating finishing processes such as mechanical softening, low-formaldehyde resin-free calendaring, and pH-neutral after-treatments to ensure safe skin contact.

How do we ensure the fabric is safe for sensitive skin?

- No AZO Dyes: We use only eco-compliant dyestuffs approved under EU REACH.

- No Formaldehyde: Our finishing is 100% resin-free or uses low-formaldehyde binders (<16ppm).

- pH Balanced: Final fabrics are washed and neutralized to pH 6.5–7.0 to match skin pH.

- Saliva-Resistant Dyes: Required for baby clothing in European and Japanese markets.

We conduct internal testing in our CNAS-certified lab and also support third-party audits. Clients receive full compliance documentation, including:

- Material Safety Data Sheets (MSDS)

- Oeko-Tex Class I Certificate (available for most satin styles)

- EN71-3 Heavy Metal Content Test (for costume or toy-related satin)

That’s why our satin is used not just for dresses, but also linings in baby jackets, soft dolls, bonnet ties, and costume trims.

Functional Add-Ons: Anti-Pilling, Static Control, Wrinkle Resistance

Satin that looks pretty in the shop must survive playgrounds and laundry cycles.

Our children's satin can be upgraded with optional anti-pilling finish, static resistance, wrinkle recovery, and antibacterial treatment—without losing its soft drape or shine.

What performance enhancements are available?

| Functional Finish | Technology Used | Benefit |

|---|---|---|

| Anti-Pilling | Acrylic dispersion coating (resin-free) | Extends fabric surface life |

| Wrinkle Resistance | Silicone micro-finish | Better drape retention |

| Static Control | Carbon-modified filaments | Less cling, safer layering |

| Antibacterial (Optional) | Zinc oxide or silver ion finish | Ideal for costume or headwear |

All functional finishes comply with CPSIA and REACH standards for kidswear. You can combine 2–3 of these into one satin style, depending on your product line. We test each treated batch for:

- Abrasion (Martindale test)

- pH and residue

- Hand feel comparison vs untreated satin

- Wash durability (20–50 cycles)

For example, a client in Canada needed satin for children's choir gowns that didn’t wrinkle on stage. We developed a 100% polyester satin with both wrinkle recovery and static control that remained smooth after folding, packing, and re-use—saving their team hours of steaming.

Flexible Customization and MOQ Support for Small and Large Brands

Whether you’re sampling a new toddler dress or restocking a million meters, we’re ready.

Fumao offers low-MOQ custom satin development (as little as 300m per color), full lab-dip support, and packaging options to help kidswear brands scale confidently.

How do we support your satin sourcing workflow?

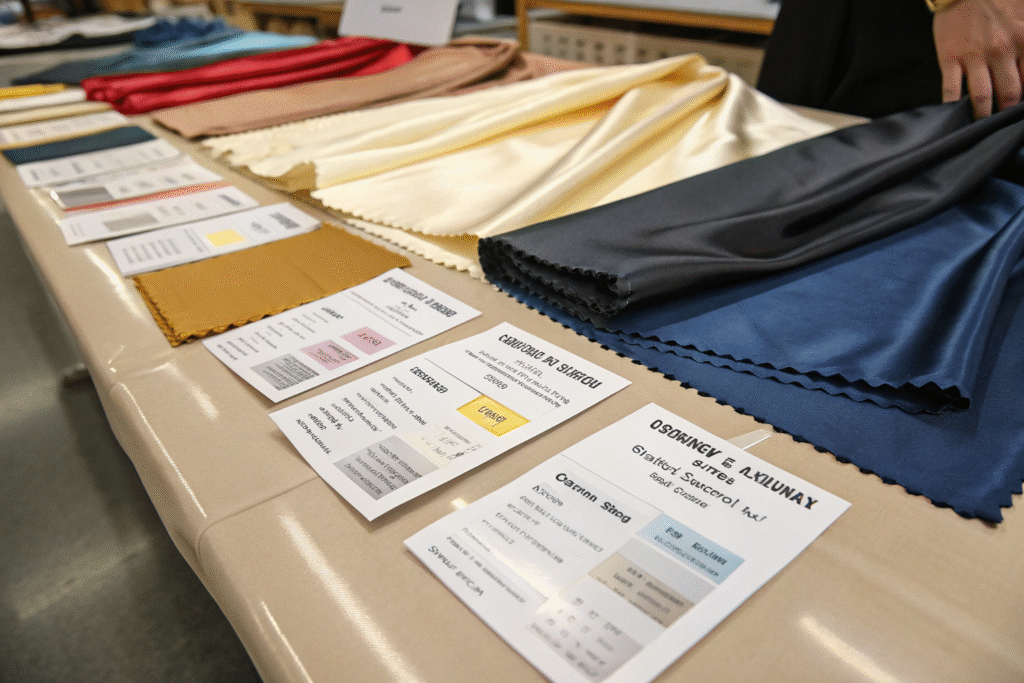

- Sample Swatching: Free shade cards and physical swatches shipped worldwide.

- Lab Dips: 2–3 day turnaround using target Pantone or fabric references.

- MOQ: 300m per color, 1000m per order—customizable per project.

- Roll Packing: Tubular, flat-folded, or reinforced for delicate satins.

- Compliance Docs: Auto-included for all satin exported for children’s clothing.

We also offer digital showroom tours and video QC inspection reports for overseas clients. This helps build trust and streamline sourcing, especially if you’re launching on tight timelines.

Our satin production is done through a network of 4 local weaving and dyeing partners under our centralized QC management system. With our end-to-end tracking, you can trace every meter from yarn to finish.

Conclusion

Kidswear satin must be more than shiny—it must be safe, soft, and strong. At Fumao, we customize every thread and finish to meet those needs. If your brand values feel, function, and safety, our satin delivers all three.