As a baby clothing manufacturer, I hear this question more and more. Brand owners like you are always looking for the next trend to captivate the market. Smart fabrics, with their promise of added functionality, are undoubtedly exciting. But when your brand's reputation hinges on safety and quality, excitement must be balanced with rigorous scrutiny. The well-being of the end-user—the child—is the non-negotiable priority for both of us.

The short answer is yes, smart fabrics can be safe for baby clothing, but only when they are developed, sourced, and manufactured with stringent safety protocols and international certifications at the core of the process. The safety isn't inherent to the technology itself; it is a result of deliberate and careful execution by every partner in the supply chain. As an experienced manufacturer, our role is to be the critical filter, ensuring that any innovative material meets the highest standards before it ever reaches a child's skin. The potential of smart fabrics is immense, but unlocking it responsibly is key.

Let's explore what smart fabrics really are, how their safety is guaranteed, and what you need to know to make an informed decision for your brand.

What are smart fabrics in modern baby clothing?

The term "smart fabrics" might sound like science fiction, but it's a reality in today's textile industry. Essentially, these are advanced materials engineered to do more than just provide warmth and coverage. They interact with the wearer or the environment. For baby clothing, this can mean fabrics that monitor body temperature, regulate moisture exceptionally well, or even feature built-in, safe sensors for health tracking. Understanding this category is the first step in evaluating its suitability for your product line.

Smart fabrics, also known as functional textiles, are materials designed with integrated technologies that provide added value beyond traditional clothing functions. This can range from phase-change materials that absorb and release heat to maintain a comfortable temperature, to moisture-wicking fabrics that keep skin drier, reducing the risk of irritation. The most advanced versions include conductive fibers that can connect to low-power devices. For a children's wear brand, the appeal is clear: it offers a powerful point of differentiation in a competitive market.

How do smart fabrics actually work?

The functionality depends on the type. Temperature-regulating fabrics often contain microcapsules embedded in the fibers. These capsules release or absorb heat in response to the baby's body temperature. Moisture-management fabrics use advanced knitting techniques and hydrophobic yarns to pull sweat away from the skin quickly. When it comes to fabrics with electronic components, the key is using ultra-soft, insulated conductive threads that are seamlessly woven in, ensuring there are no hard or uncomfortable parts against the baby's delicate skin. The technology is sophisticated, but the principle is always comfort and safety.

What are the main benefits for children's wear brands?

Integrating smart fabrics allows your brand to offer unparalleled value. You can market garments that genuinely enhance comfort, like a sleepsuit that helps prevent overheating—a major concern for new parents. This addresses a real parenting pain point and builds immense brand loyalty. Furthermore, it positions your brand as an innovative leader. In the mid-to-high segment, this technological edge justifies a premium price point and attracts discerning customers who seek the best for their children, aligning with current children's fashion trends.

How can I verify the safety of smart fabrics for babies?

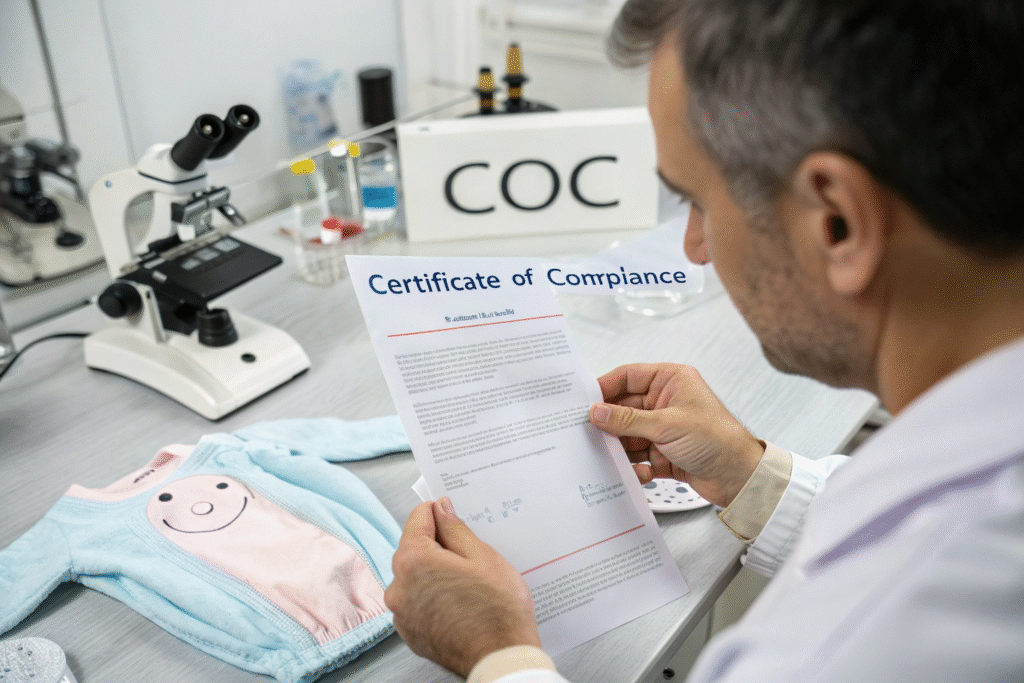

This is the most critical question for any responsible brand owner. Safety verification goes far beyond a simple supplier claim. It requires a proactive, evidence-based approach. You need a manufacturing partner who treats safety not as an assumption but as a verifiable fact, backed by a transparent and documented process.

Verifying safety is a multi-step process that hinges on demanding and validating internationally recognized certifications specific to children's products. The first and most important step is to insist on a Certificate of Compliance (CoC) for all smart fabric materials, referencing strict standards like the U.S. Consumer Product Safety Improvement Act (CPSIA) and OEKO-TEX® STANDARD 100 Class I. Class I is crucial as it is the highest level for articles intended for babies and toddlers, ensuring the materials are free from harmful levels of over 100 regulated substances.

Which certifications should I require from my supplier?

| Always require certifications that prove the fabric is safe for direct, prolonged skin contact with infants. The gold standards are: | Certification | Focus Area | Why It Matters for Babies |

|---|---|---|---|

| OEKO-TEX® STANDARD 100 Class I | Tests for harmful substances | Specifically for infants; ensures no toxic dyes or chemicals. | |

| CPSIA Compliance | Lead and phthalates content | U.S. legal requirement for children's products. | |

| GRS (Global Recycled Standard) | If using recycled smart materials | Verifies recycled content and responsible production. |

Your manufacturer should provide these certificates without hesitation. For any electronic elements, additional electrical safety certifications from bodies like UL or IEC may be necessary.

What questions should I ask about material composition?

You must ask detailed questions. What specific materials make the fabric "smart"? Are the phase-change materials non-toxic and securely encapsulated? What type of conductive threads are used, and are they insulated and flexible? A reliable supplier will provide a detailed breakdown of the material composition and have technical data sheets ready. This level of transparency is a strong indicator of a trustworthy partner and is essential for your own due diligence and quality control processes.

What are the biggest risks of using smart fabrics in baby apparel?

Acknowledging the risks is not about fearmongering; it's about responsible sourcing. Being aware of potential pitfalls allows you and your manufacturer to put preventative measures in place. The biggest risks typically stem from cutting corners—either in the quality of the base material or in the manufacturing integration process.

The primary risks involve the potential for skin irritation from poorly integrated components, the failure of the smart functionality leading to product recalls, and the use of non-compliant chemicals in the fabric's treatment. For instance, if microcapsules in a temperature-regulating fabric are not durable, they could break and release contents onto the skin. Similarly, if a conductive thread is not properly insulated, it could cause discomfort or pose a safety hazard.

How can poor manufacturing create safety issues?

Even the safest material can become a hazard if integrated incorrectly. A common risk is the improper attachment of electronic modules. They must be secured in a way that prevents them from being detached, presenting a choking hazard. The sewing process must not puncture or damage the smart components. This is why choosing a factory with experience in handling these advanced materials is non-negotiable. Their expertise in garment construction techniques for delicate functional textiles is your first line of defense against manufacturing-related risks.

Are there long-term durability concerns?

Absolutely. Baby clothing undergoes rigorous use—frequent washing, stretching, and exposure to various elements. A smart fabric must maintain its integrity and safety through this entire lifecycle. Will the moisture-wicking property wash out after 20 cycles? Will the conductive threads break? You need your manufacturer to conduct rigorous testing, including multiple wash cycles and abrasion tests, to simulate the product's lifespan. This ensures the product durability meets your brand's standards and protects the end-user throughout the garment's use.

Why is partnering with an experienced manufacturer crucial for smart fabric projects?

The complexity of smart fabrics elevates the role of your manufacturing partner from a simple producer to a technical collaborator. An experienced manufacturer does not just sew clothes; they provide the essential engineering and quality assurance backbone that transforms innovative materials into safe, reliable, and market-ready products.

An experienced manufacturer is crucial because they possess the specialized knowledge to select reputable smart fabric suppliers, the technical expertise to handle advanced materials during production, and the rigorous quality control systems to catch potential issues before they become costly recalls. They understand the unique challenges, from preventing needle damage during sewing to ensuring consistent performance across a full production run. This expertise is your single greatest risk mitigation strategy.

How does your experience with international standards benefit my order?

We have spent decades building a deep understanding of the safety and quality standards required by your target markets in North America and Europe. This knowledge is proactively applied to every order. When you partner with us, we don't just follow your instructions; we act as an extension of your quality team. We will advise on the most suitable and certified smart materials, ensure the production process adheres to ISO standards, and manage the entire supply chain logistics with a focus on compliance and traceability. This end-to-end oversight is invaluable.

What specific questions should I ask a potential manufacturer?

To gauge a manufacturer's capability, move beyond price and ask pointed questions: "Can you provide a detailed risk assessment for this smart fabric project?" "What is your protocol for testing the durability of the smart functionality?" "Show me examples of similar projects you have completed, including the certifications obtained." Their answers will reveal their depth of experience. A partner like us will have clear, documented processes and a track record we are proud to share, ensuring your venture into smart fabrics is built on a foundation of trust and expertise.

Conclusion

The journey into smart fabrics for baby clothing is filled with opportunity, but it must be navigated with caution and expertise. The safety of these innovative materials is not a given; it is a carefully engineered outcome achieved through stringent certification, transparent sourcing, and masterful manufacturing. The key takeaway is that the risks are manageable when you have the right partner—one who prioritizes safety as much as innovation.

For brand owners looking to differentiate their line with cutting-edge, safe, and high-quality smart fabric baby clothing, the choice of manufacturer is the most critical decision. If you are ready to explore how smart fabrics can elevate your brand with zero compromise on safety, let's talk. We have the experience, the certifications, and the commitment to quality to bring your vision to life responsibly. Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to discuss your specific requirements and start a partnership built on trust and excellence.