In the apparel industry, digital twin samples are gaining attention as an alternative to physical prototypes. These 3D virtual garments replicate real fabric, construction, and drape. The main question for buyers and manufacturers is simple: are digital twin samples truly cost-effective? The answer depends on production scale, investment in technology, and the balance between digital and physical workflows.

Digital twin samples save costs by reducing prototype rounds, shortening approval timelines, and lowering logistics expenses, but they require upfront investments in software, training, and hardware.

As a manufacturer of children’s clothing, I have seen how this shift can reshape development cycles. In this article, I will explore the cost benefits, limitations, and best use cases for digital sampling.

How do digital twin samples reduce costs?

The most significant advantage of digital twin samples is cost reduction. Traditional prototypes require materials, sewing, and international shipping, while a digital model can be generated and shared instantly online.

Digital twins reduce costs by lowering sampling rounds, saving courier fees, and minimizing fabric waste.

Why are digital twins cheaper than traditional samples?

A physical prototype often costs $50–200, depending on garment complexity and logistics. If a brand develops dozens of SKUs, this adds up quickly. By contrast, digital tools like CLO3D or Browzwear allow adjustments before any fabric is cut, lowering the number of required physical samples.

How do they reduce global logistics costs?

Instead of shipping samples overseas, manufacturers send files. Studies from Apparel Resources show that digital-first workflows reduce shipping by up to 70%, saving both money and time while also lowering the carbon footprint.

What investments are required for digital sampling?

Although digital twins reduce long-term costs, they require upfront investments. Software licenses, skilled staff, and updated hardware are necessary to implement 3D workflows.

Costs include monthly software fees, training for technical accuracy, and hardware capable of advanced rendering.

What are the software and training expenses?

Programs like Optitex or CLO3D charge about $50–100 per user per month. Teams also need training to achieve true-to-life fabric simulation. According to Lectra, companies that invest in training improve sample accuracy and reduce final approval delays.

Why does hardware matter?

3D rendering requires strong processors and graphics cards. Without these, drape and fit accuracy may suffer. However, the investment often pays for itself after one or two seasons compared with ongoing sample-making costs.

When are digital twin samples most effective?

Digital twins deliver maximum value in high-volume production, international sourcing, and markets where speed is critical.

They are most effective for large brands, wholesalers, and manufacturers needing fast approvals across multiple product lines.

Why do global brands benefit most?

Large retailers launch hundreds of styles per season. Digital twins let them reduce waste, accelerate approvals, and align with sustainability targets. Reports from Fashion United show that major brands adopting digital sampling save millions annually.

How do small buyers benefit?

Even smaller businesses gain by previewing designs digitally before committing to orders. Case studies from Just Style highlight that digital twins reduce costly misunderstandings and rejected shipments, which are common pain points in sourcing from Asia.

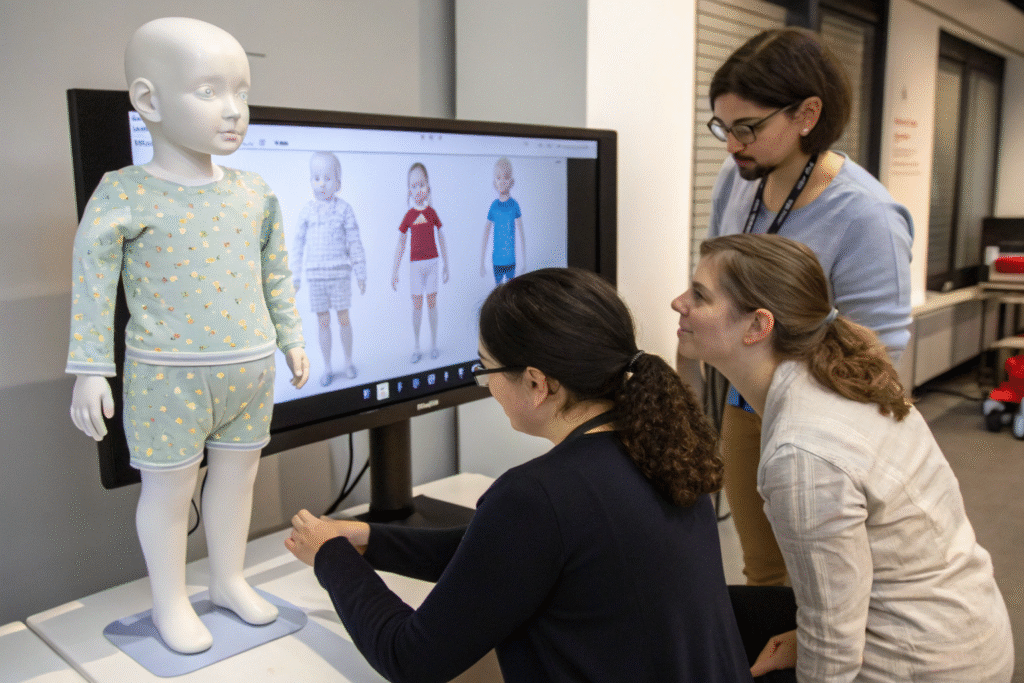

Do digital samples fully replace physical ones?

Despite their advantages, digital twins do not fully replace physical garments. Final fit approval, hand-feel evaluation, and marketing shoots still require real prototypes.

Digital samples reduce the number of prototypes needed, but physical samples remain essential for final validation.

Why is physical testing still necessary?

Parents buying children’s wear focus on softness and comfort. Even advanced software cannot fully replicate tactile qualities. Textile World confirms that sensory evaluation remains irreplaceable in apparel.

How many physical samples are still required?

Brands usually cut sampling rounds from four to one or two. According to Apparel Insider, this hybrid approach reduces development time by up to 50%, combining efficiency with quality assurance.

Conclusion

Digital twin samples provide a powerful way to reduce costs, save time, and support sustainability in apparel development. They require initial investments in technology and training, but the long-term savings are significant. For both large and small buyers, digital sampling offers a competitive edge in fast-moving markets.

At Shanghai Fumao, we have already integrated digital twin technology into our children’s wear development. This allows us to deliver faster turnarounds, fewer revisions, and more sustainable production. If you are ready to explore advanced sampling methods for your brand, please contact our Business Director Elaine at elaine@fumaoclothing.com. Together, we can innovate your collection while reducing costs.