The apparel industry is undergoing a significant transformation in product development. One of the most notable innovations is the adoption of 3D virtual prototyping as a complement to traditional physical sampling. Instead of waiting weeks for cut-and-sew iterations, design and merchandising teams can now visualize garments digitally, apply modifications in real time, and share files instantly with global partners.

3D prototypes are not yet replacing physical samples entirely, but they are increasingly reducing the volume of physical iterations required.

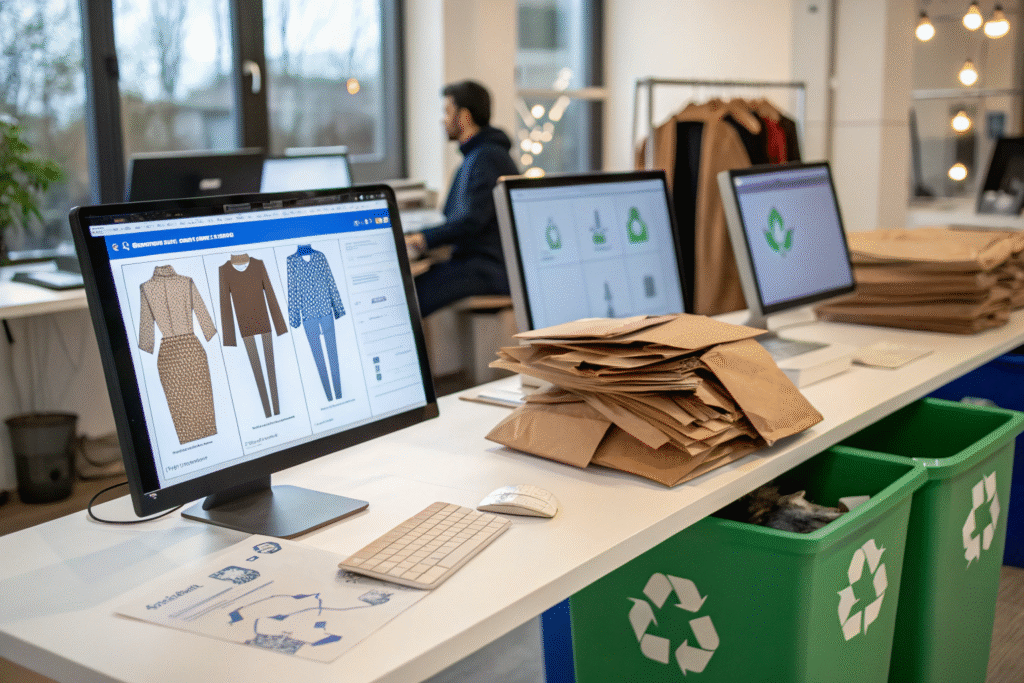

Below is an overview of why 3D prototyping is gaining momentum and how it integrates into modern apparel workflows.

Speed and Cost Efficiency

Conventional sampling involves fabric procurement, manual cutting, sewing, and shipping—processes that can extend lead times by several weeks. Each design change requires another round of sampling, adding cost and delay.

3D CAD software enables rapid visualization and pattern adjustment, lowering both development costs and cycle time.

Why do brands adopt 3D early in the cycle?

Platforms such as CLO3D and Browzwear allow designers to modify silhouettes, seam placements, and print layouts instantly.

Supplier perspective

Factories can focus resources on producing only the final approved prototype, reducing waste in sampling yards and machine time.

Sustainability and Waste Reduction

Physical samples consume fabric and trims that often never enter final production. They also generate carbon emissions through global courier shipping.

3D sampling supports sustainability goals by reducing raw material waste and lowering logistics impact.

Why does this align with industry priorities?

A McKinsey report emphasizes that digital product creation helps apparel companies achieve ESG targets and reduce excess inventory.

Buyer implications

Digital previews allow wholesale buyers to review and approve collections remotely, cutting down on air-freight samples.

Buyer Engagement and Virtual Showrooms

3D samples enhance buyer interaction by enabling a detailed examination of virtual garments. They can rotate 360°, zoom in on seams, and visualize fit on digital avatars.

This increases buyer confidence and facilitates global collaboration without extensive physical shipments.

Commercial applications

Brands now host virtual showrooms where international buyers can view digital collections before committing to production.

Limitation

While visual fidelity is high, tactile elements such as hand feel, drape, and elasticity still require physical verification.

Limitations and Hybrid Adoption

Despite its advantages, 3D prototyping cannot yet replace physical testing in areas such as fit validation, wash performance, and compliance with children’s safety standards.

The prevailing model is hybrid: digital sampling for ideation and line reviews, followed by limited physical samples for final approval.

Why is a hybrid approach necessary?

Regulations such as CPSIA in the U.S. require physical testing for small parts safety, flammability, and durability.

How do leading companies integrate both?

Firms like Nike and Adidas rely heavily on 3D simulation for design but still produce physical prototypes for compliance and retail-ready validation.

Conclusion

3D prototyping is not eliminating physical samples but is fundamentally reshaping apparel development workflows. It accelerates time-to-market, reduces costs, and aligns with sustainability targets. Physical samples remain indispensable for compliance, tactile evaluation, and marketing photography.

At Shanghai Fumao, we integrate 3D design technology with traditional prototyping. This allows our global partners to shorten design approval cycles while maintaining rigorous quality assurance in final production.

👉 For hybrid sampling solutions that combine digital efficiency with physical accuracy, contact our Business Director Elaine at elaine@fumaoclothing.com. We deliver reliable children’s wear development supported by both 3D visualization and certified physical QC.