Adjustable waist toddler pants are a highly practical category in children’s apparel. They give toddlers room to grow, reduce return rates for retailers, and meet parents’ demand for both comfort and durability. For sourcing teams, finding the right supplier involves more than price negotiations—it requires careful consideration of factory capability, waistband construction, fabric safety, and compliance with international standards.

To secure reliable production of adjustable waist toddler pants, buyers should focus on specialized manufacturers, validate construction methods, ensure material certifications, and align output with strict QC systems.

Identify Specialized Manufacturers

The sourcing process begins with identifying the right type of manufacturer. Not all apparel factories have expertise in children’s wear, and even fewer specialize in adjustable waist garments. Buyers should seek facilities with a proven track record in toddler clothing, especially those familiar with CPSIA safety standards and elastic waistband production.

Working with specialized factories minimizes the risk of defective waist mechanisms and ensures long-term product consistency.

Why does specialization matter?

Children’s wear requires compliance with strict safety standards and child-safe trims. Factories experienced in this niche understand these requirements better than general apparel suppliers.

Where can buyers find them?

Verified platforms such as Alibaba and international trade fairs like Canton Fair or CBME (Children Baby Maternity Expo) provide direct access to audited children’s apparel manufacturers.

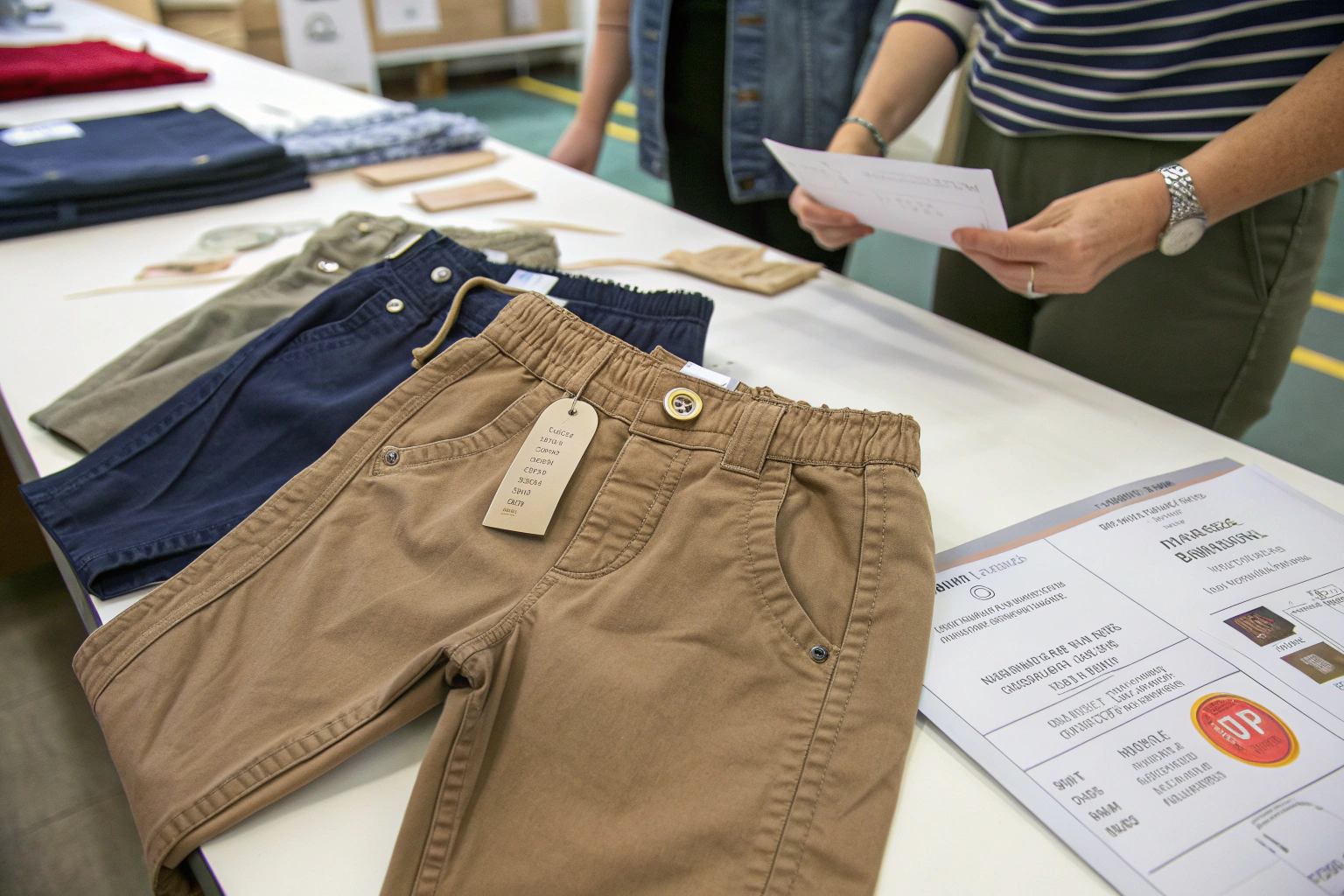

Verify Waistband Construction Methods

Once a potential supplier is identified, the next step is to examine waistband construction. Adjustable waist toddler pants usually feature buttonhole elastic systems or drawstring mechanisms. Among these, buttonhole elastic is preferred because it allows secure adjustments and complies with children’s apparel safety standards.

Inspection should confirm durable stitching, safe button sizing, and consistent elastic recovery after multiple washes.

Why is buttonhole elastic preferred?

It enables incremental adjustments without posing choking hazards, aligning with CPSIA safety requirements.

How should buyers verify quality?

Pre-production samples should undergo tensile strength testing and wash-cycle durability assessments before mass production.

Check Fabric and Component Certifications

Even with solid construction, safety also depends on certified fabrics and trims. Buyers should confirm that all materials—including elastic bands, buttons, and fabrics—carry certifications such as OEKO-TEX® Standard 100 Class I, CPSIA compliance, and REACH certification for EU markets.

Certified inputs ensure that garments remain safe for toddlers’ sensitive skin and meet the chemical safety thresholds required in regulated markets.

Why are certifications essential?

They serve as proof of compliance and protect brands from recalls or penalties. OEKO-TEX certification is particularly important for babywear applications.

What should procurement teams prioritize?

Always request up-to-date certificates and verify them directly with issuing organizations to prevent fraudulent claims.

Align Production With International Standards

After supplier selection and material approval, the final focus is production execution. Factories should integrate AQL inspections, flammability tests, and needle detection systems into their QC workflows. Buyers benefit from partnering with manufacturers who already work with independent inspection bodies such as Intertek or SGS.

Aligning production with international standards ensures that garments meet specifications consistently and are accepted in global markets.

Why is QC integration critical?

It prevents shipment delays, reduces defect rates, and provides independent assurance of product quality.

How do global buyers gain value?

Structured QC lowers return rates, increases retailer trust, and strengthens long-term supply chain stability.

Conclusion

Sourcing adjustable waist toddler pants requires a structured approach. Buyers should start by selecting specialized manufacturers, validate waistband construction methods, confirm certified fabrics and trims, and enforce QC aligned with international standards. This ensures that products are safe, durable, and commercially viable.

At Shanghai Fumao, we specialize in adjustable waist toddler pants with certified buttonhole elastic systems. Our production integrates OEKO-TEX® certified fabrics, CPSIA-compliant trims, and rigorous quality inspections.

👉 To source factory-direct adjustable waist toddler pants, contact our Business Director Elaine at elaine@fumaoclothing.com. We deliver safe, compliant, and customizable solutions with DDP global shipping.