In the children’s apparel supply chain, inspection protocols are critical for safeguarding product integrity, ensuring compliance with regulatory standards, and maintaining brand reputation. Given that children’s garments fall under the most stringent consumer safety regulations, inspections must verify not only aesthetic and constructional quality but also chemical safety, physical performance, and labeling accuracy.

Core inspection methodologies in children’s clothing include raw material audits, in-line production monitoring, final random inspection (FRI), accredited laboratory testing, and compliance verification.

Raw Material and Trim Inspection

Inspection begins at the raw material stage. Fabrics, threads, zippers, snaps, and buttons are examined for defects, dimensional stability, and compliance with restricted substances lists (RSLs).

Pre-production material inspection prevents systemic failures caused by substandard inputs.

Why is raw material auditing essential?

Children’s apparel requires certified substrates, often OEKO-TEX® Standard 100 Class I or CPSIA-compliant. Early-stage testing ensures conformity.

Common checkpoints

- GSM measurement and color shade banding

- Trim tensile strength and pull resistance

- Needle detection scans for metallic contamination

In-Line Production Monitoring

During assembly, in-line quality control (QC) tracks seam integrity, stitch density, and compliance with tech pack specifications. Sampling protocols, often AQL-based (Acceptable Quality Limit), are applied across multiple workstations.

Real-time monitoring minimizes rework rates and stabilizes process capability.

What parameters are monitored?

- Stitch per inch (SPI) and seam allowances

- Correct label application and placement

- Alignment with size set specifications

Why is this step critical?

Defects caught mid-line avoid full-batch rejections and mitigate downstream bottlenecks.

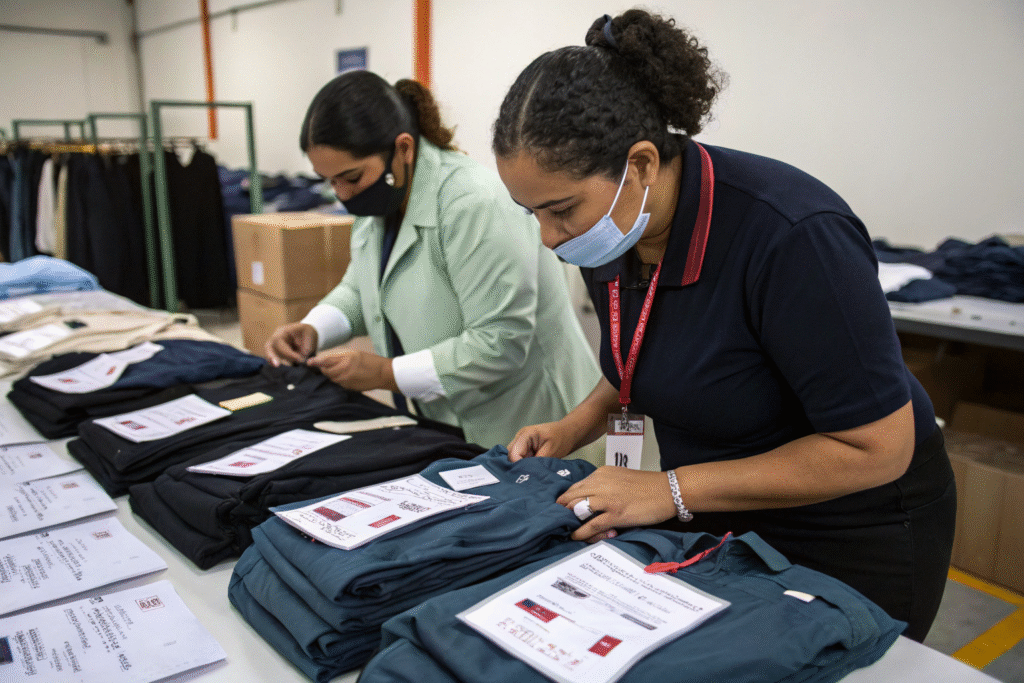

Final Random Inspection (FRI)

The Final Random Inspection is conducted once production is complete and goods are packed. Inspectors select shipping cartons randomly, applying AQL sampling standards to validate shipment quality.

FRI provides independent assurance that deliverables match approved pre-production samples.

Key checkpoints

- Garment dimensions and tolerance verification

- Shade consistency across dye lots

- Packaging conformity and barcode validation

Why is FRI vital for buyers?

It mitigates risk of post-shipment disputes, ensuring contractual quality obligations are met. Third-party inspection providers like Intertek specialize in FRIs for apparel exports.

Laboratory Testing and Safety Validation

Independent laboratory testing verifies compliance with statutory and retailer-specific requirements. Testing protocols cover flammability, chemical residue levels, colorfastness, tensile strength, and small parts safety.

Laboratory validation is mandatory for export markets such as the U.S. and EU.

Standard test regimes

- Flammability compliance under CPSC regulations

- Lead, phthalate, and formaldehyde testing for trims and prints

- Colorfastness protocols defined by AATCC

Why is lab testing non-negotiable?

Retailers require accredited test reports before onboarding children’s apparel lines.

Compliance and Label Verification

Label inspections ensure conformity with fiber content laws, care labeling acts, and child-specific safety requirements. Incorrect labeling may result in regulatory penalties or forced recalls.

Accurate compliance labeling is an integral part of the inspection process.

Applicable frameworks

- U.S. FTC Textile and Wool Acts

- EU Textile Regulation (Regulation (EU) No 1007/2011)

- CPSIA tracking labels for children’s products

Strategic importance

Label compliance enhances transparency for consumers and simplifies regulatory audits.

Conclusion

Inspection methods for children’s clothing span the full production lifecycle—from raw material audits to final shipment checks. These protocols protect consumers, reduce brand liability, and ensure regulatory compliance across export markets.

At Shanghai Fumao, we implement integrated QC systems, combining AQL inspections, OEKO-TEX® sourcing, and CPSIA testing. Our inspection framework guarantees that every garment meets the highest international standards for safety and quality.

👉 To secure a compliant and efficient QC strategy for your children’s apparel sourcing, contact our Business Director Elaine at elaine@fumaoclothing.com. We deliver transparent inspection processes and reliable supply chain support.