The children's sleepwear market stands apart from other apparel categories due to an exceptionally high level of regulatory scrutiny and mandatory safety standards. This isn't bureaucratic overreach; it's a direct, data-driven response to a tragic history of preventable injuries. As a manufacturer operating within this tightly regulated space, I can affirm that these controls are the non-negotiable bedrock of the industry, designed to protect the most vulnerable consumers during their most vulnerable state: sleep. Understanding the "why" is essential for any brand looking to enter or succeed in this sector.

The kids sleepwear market is strictly controlled because of the profound and proven fire hazard associated with loose-fitting garments near open flames or heat sources. Regulations, primarily focusing on flammability performance and safe design, are enforced to prevent severe burns and fatalities, making compliance a matter of life-saving legal and ethical obligation.

This control manifests in rigorous fabric testing, mandatory labeling, and specific design rules that govern everything from fit to fiber content. Let's explore the historical context, the specific regulatory frameworks, and the profound implications for brands and manufacturers.

What is the Historical Context Behind Sleepwear Regulations?

The stringent controls in place today were born from tragedy. Throughout the mid-20th century, loose-fitting, highly flammable cotton nightgowns and pajamas were commonplace. When these garments came into contact with open flames from heaters, stoves, or candles, they would ignite rapidly, causing devastating and often fatal burns to children.

Landmark incidents and advocacy led to the U.S. Flammable Fabrics Act (FFA) of 1953 and, more specifically, the Children's Sleepwear Standards (16 CFR Parts 1615 and 1616) enacted by the U.S. Consumer Product Safety Commission (CPSC) in the early 1970s. These regulations were a watershed moment, drastically reducing sleepwear-related burn injuries and deaths by mandating that garments either be made from inherently flame-resistant fabric or be snug-fitting to minimize air circulation (which fuels fire).

How Did Regulatory Evolution Shape Today's Market?

The initial regulations led to the widespread use of chemical flame retardants (like Tris) on sleepwear. However, subsequent health studies in the 1970s raised concerns about the potential carcinogenicity of these chemicals. This prompted another regulatory shift. The standards were amended to emphasize two primary pathways to compliance:

- Inherently Flame-Resistant Fabrics: Synthetic fibers like polyester that self-extinguish.

- "Close-Fitting" Design: Garments that are snug to the body, reducing the air layer between fabric and skin that supports combustion, regardless of the fabric's inherent flammability.

This evolution reflects the ongoing balance between fire safety and chemical safety, a core tension that still defines the market.

What Are the Key Regulatory Bodies and Standards Globally?

While the U.S. CPSC standards are among the strictest, similar frameworks exist worldwide:

- USA: CPSC Standards 16 CFR 1615 & 1616 for sizes 0-14. They define test methods, labeling, and record-keeping requirements.

- Canada: Hazardous Products (Children's Sleepwear) Regulations under the Canada Consumer Product Safety Act, closely aligned with U.S. standards.

- Australia/New Zealand: AS/NZS 1249:2014 is the mandatory standard, covering nightwear and limited daywear with similar categories based on flammability and fit.

- European Union: While there is no sleepwear-specific regulation as strict as the US, the General Product Safety Directive (GPSD) requires all products to be safe. Standards like EN 14878 (Textiles - Burning behaviour of children's nightwear) provide a test method and specification, and the REACH regulation heavily restricts harmful chemicals.

Non-compliance in these markets can lead to forced recalls, fines, and irreparable brand damage.

What Are the Specific Flammability and Testing Requirements?

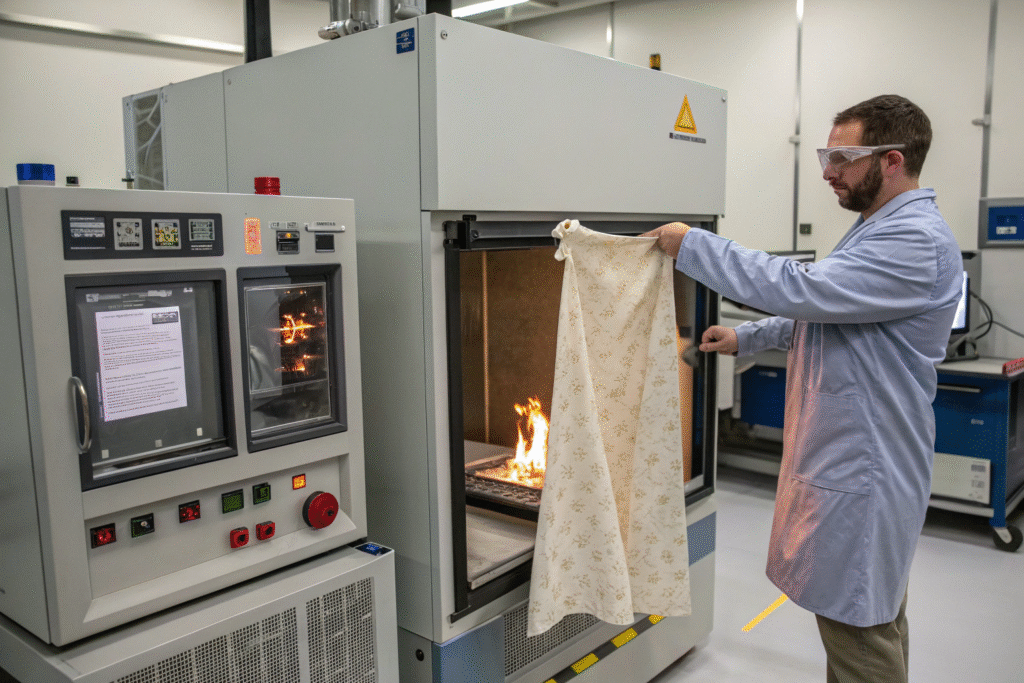

The core of sleepwear control is the mandatory flammability test. The regulations specify a precise scientific protocol that all garments must pass to be legally sold. This isn't a voluntary quality check; it's a legally enforced barrier to entry.

The standard test involves suspending a fabric sample vertically in a controlled chamber and applying a small, standardized flame to its bottom edge for a specified time. Measurements are then taken of the char length (how far the fabric burns) and the afterflame/afterglow time. To pass, the fabric must self-extinguish quickly and have a char length under a specified limit (e.g., 7 inches for the US standard).

What is the Difference Between "Inherently Flame-Resistant" and "Treated" Fabrics?

- Inherently Flame-Resistant (FR) Fabrics: These are fibers that possess natural resistance to ignition and burning. The most common is 100% polyester, which melts and drips away from a flame rather than sustaining combustion. Some modacrylic blends also qualify. These fabrics maintain their FR properties for the life of the garment and through repeated washings.

- Chemically Treated FR Fabrics: These are fabrics (often cotton or cotton blends) that have been coated or finished with chemical flame retardants. Due to health and environmental concerns, and because washing can degrade the treatment, this pathway is far less common today for children's sleepwear. The regulatory focus has shifted heavily toward inherent FR or tight-fitting design.

How Does "Close-Fitting" Design Serve as a Compliance Alternative?

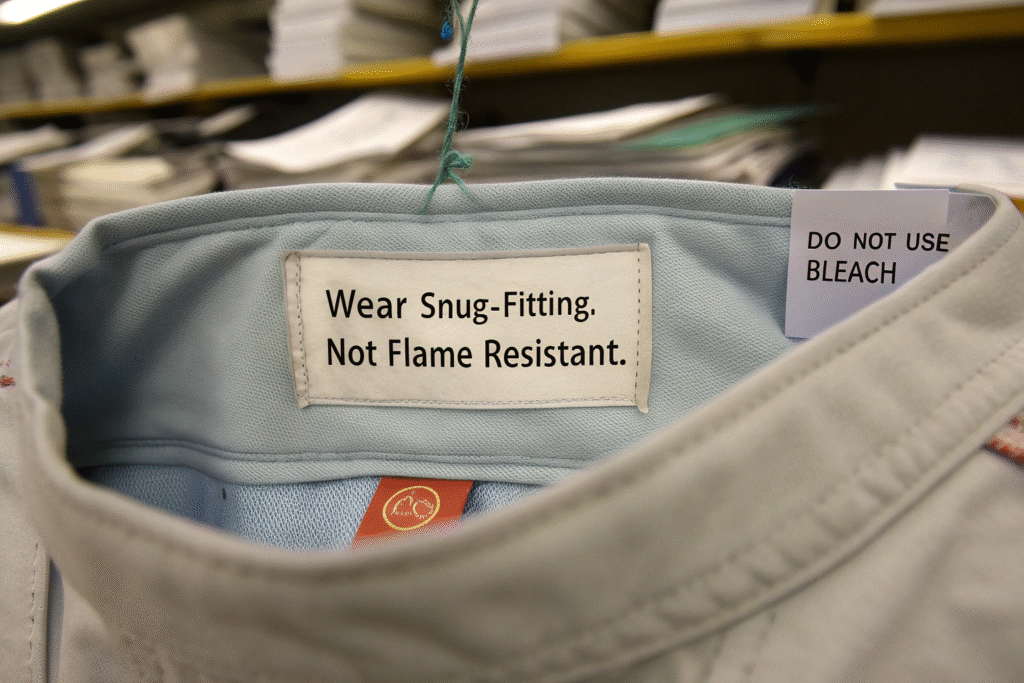

If a garment does not use an inherently FR fabric, it must meet stringent "close-fitting" or "snug-fitting" criteria as defined in the regulations. This is not subjective; there are maximum measurement allowances for chest, waist, seat, and upper arm circumference, as well as length. The goal is to minimize the air gap between the garment and the skin. A tight-fitting cotton pajama set can be compliant because, even if the cotton ignites, the lack of oxygen between fabric and skin limits the burn rate and severity, potentially allowing a child to remove the garment quickly. This pathway has popularized the classic, snug-fitting cotton knit pajama.

How Do Labeling and Documentation Enforce Compliance?

The regulations extend beyond the product itself to rigorous tracking and communication requirements. Proper labeling is a legal mandate that informs consumers and allows for traceability in the event of an incident or recall.

Mandatory labels include a permanent, sewn-in label stating the garment's compliance (e.g., "Wear Snug-Fitting. Not Flame Resistant." or "Flame Resistant"), care instructions that must not degrade safety (e.g., "Do not use bleach" on treated fabrics), and often a distinctive hangtag. Manufacturers and importers must also maintain detailed production records and test reports for at least three years.

What Are the Consequences of Mislabeling or Non-Compliance?

The penalties are severe because the risks are life-threatening. The U.S. CPSC and its international equivalents have the authority to:

- Issue a Mandatory Recall of all non-compliant products from store shelves and consumers' homes.

- Levy Significant Civil Penalties (fines reaching millions of dollars for companies).

- Pursue Criminal Charges in cases of willful violations.

- Publicly List the Violation, causing catastrophic reputational damage.

A single compliance failure can bankrupt a small brand and tarnish a large one permanently. This makes the choice of a manufacturer with a flawless compliance track record absolutely critical.

Why is Third-Party Testing and Certification Essential?

Brands cannot self-certify. Sleepwear must be tested by a CPSC-accepted, third-party laboratory for the specific market. Labs like Intertek, SGS, or Bureau Veritas perform the standardized flammability tests and issue official reports. For a manufacturer, having established relationships with these labs and a rigorous in-house quality control (QC) protocol that includes pre-shipment verification of fit measurements and labeling is a fundamental part of the service.

What Are the Implications for Design, Sourcing, and Manufacturing?

These controls directly dictate nearly every aspect of product development. Creativity operates within a strict safety framework. This impacts fabric selection, pattern-making, trim choices, and production planning.

Designers must start with compliance as the first parameter. Sourcing involves vetting fabric mills for reliable FR certification or high-quality, stable knits for snug-fit garments. Manufacturing requires precision in cutting and sewing to ensure every single garment, across all sizes, meets the exacting measurement standards for "close-fitting" if that is the chosen path.

How Do Regulations Influence Fabric and Trim Choices?

Beyond the main fabric, every component must be considered:

- Trims: Lace, ribbons, and bindings must also be FR or used in very limited quantities.

- Thread: Must be compatible (e.g., polyester thread on polyester fabric).

- Decorative Elements: Large, loose appliqués or fluffy trims are generally prohibited as they can pose both a flammability and choking hazard.

The entire bill of materials (BOM) must be evaluated for compliance, making sourcing more complex than for general apparel.

Why is Production Consistency and Quality Control Paramount?

A deviation of a few centimeters in a chest measurement can render an entire batch non-compliant. Therefore, manufacturing sleepwear demands exceptional consistency. This requires:

- Precise Pattern Grading: Ensuring all size increments maintain the required snug fit.

- In-Line QC Checks: Regularly measuring samples directly off the production line.

- Final Audit Inspection: A comprehensive check of labeling, measurements, and workmanship against the standard before shipment.

A manufacturer specializing in sleepwear, like Fumao, has these protocols embedded in its production DNA, providing brands with the assurance that every unit shipped is audit-ready.

Conclusion

The strict control of the kids sleepwear market is a powerful and necessary example of regulation serving its highest purpose: the prevention of injury and the protection of life. It transforms sleepwear from a simple commodity into a scientifically engineered product category where safety is the primary and non-negotiable feature. For brands, this means accepting that success is contingent upon unwavering commitment to compliance, which in turn requires a deep partnership with a knowledgeable, meticulous, and certified manufacturer.

Navigating this landscape is complex, but it is the price of entry for operating in a sector with zero tolerance for error. At Fumao Clothing, our expertise encompasses the full spectrum of sleepwear compliance—from sourcing certified FR fabrics and engineering snug-fit patterns to managing third-party testing and ensuring flawless labeling. If you are developing a sleepwear line, partner with a manufacturer who respects the gravity of these controls. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to build a collection that prioritizes safety as much as style and comfort.