Creating a comprehensive technical package represents one of the most critical steps in children's wear production, yet many brands underestimate its importance or include insufficient detail. As a manufacturer working with American and European children's wear brands, I've seen how the quality and completeness of a tech pack directly correlates with production success, sample accuracy, and ultimately, the final product's quality.

A complete kids clothing tech pack must include detailed technical drawings, comprehensive measurement specifications, materials information, construction details, and compliance requirements specific to children's wear safety standards. This document serves as the universal language between design vision and manufacturing execution, ensuring all parties share identical understanding of every garment detail.

The most successful brands treat their tech packs as living documents that evolve throughout development, while manufacturers rely on these specifications to deliver products that match design intent while meeting quality and safety expectations.

Why Are Technical Drawings Fundamental?

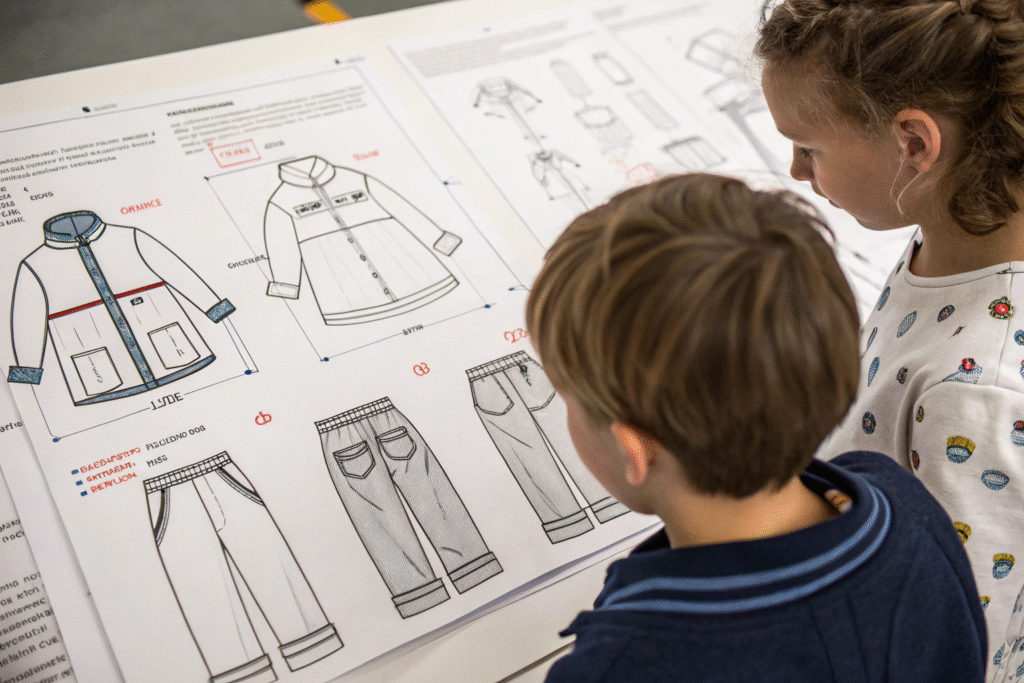

Technical drawings provide the visual foundation of any tech pack, translating design concepts into precise illustrations that manufacturers can execute accurately.

These drawings must communicate silhouette, proportions, and design details through multiple views with consistent scale and clear annotation that leaves no room for interpretation.

What Views and Details Are Essential?

Complete technical drawings should include front, back, and side views with consistent scale and proportion. For complex designs, include detail callouts for special elements like pockets, collars, plackets, or unique seam treatments. Children's wear specifically requires attention to safety-related details like neck opening measurements, drawstring specifications, and small parts attachment. The American Apparel Producers Network recommends including both flat sketches and, when helpful, limited three-dimensional representations to clarify design intent for complex styles.

How Should Annotations Communicate Design Intent?

Annotations must clearly identify every design element, stitch type, and special treatment using industry-standard terminology. Callouts should reference specific sections of the tech pack where additional detail is provided, creating clear connections between the visual representation and written specifications. At Fumao, we've developed standardized annotation systems that ensure consistent interpretation across language barriers, particularly important for international manufacturing partnerships.

What Measurement Specifications Ensure Proper Fit?

Comprehensive measurement charts form the quantitative foundation of any tech pack, specifying exact dimensions for each size and key measurement points.

Children's wear measurements require particular attention to proportion differences across age groups and accommodation of growth patterns while maintaining safety requirements.

Which Key Measurements Differ in Children's Wear?

Beyond standard body measurements, children's wear requires specific attention to neck opening circumferences (for safety and ease of dressing), rise measurements (for diaper accommodation or comfort), and sleeve/leg lengths that accommodate growth. These measurements must reflect the unique proportions of each age group rather than simply scaling down adult measurements. Our technical team uses age-specific measurement standards developed through anthropometric research on thousands of children to ensure patterns reflect actual body proportions.

How Should Tolerance Ranges Be Specified?

Clearly defined tolerance ranges for each measurement prevent quality issues while allowing for manufacturing realities. Critical measurements like neck openings and safety-related dimensions typically have tighter tolerances (±¼ inch) than less critical areas (±½ inch). Specifying these ranges explicitly prevents misunderstandings about which measurements require precision versus those allowing reasonable variation. The Quality Assurance Institute provides guidelines for appropriate tolerance ranges based on garment type and children's age group.

What Materials Information Is Crucial?

Complete materials specification ensures consistency in fabric, trim, and component selection, directly impacting the final product's look, feel, performance, and safety.

Children's wear requires particular attention to material safety certifications, durability requirements, and comfort factors specific to young wearers.

What Fabric Specifications Are Essential?

Beyond basic composition, include fabric weight (GSM), stretch percentage and recovery, shrinkage limits, colorfastness requirements, and any special finishes or treatments. For children's wear, specifically note safety certifications like OEKO-TEX Standard 100 or compliance with flammability standards. We require brands to provide fabric testing documentation for all materials used in production, ensuring they meet our quality and safety standards before manufacturing begins.

How Should Trims and Components Be Specified?

Detail every component including thread type and weight, zipper specifications (length, type, tape composition), button materials and attachment methods, elastics (width, composition, recovery), and any labels or tags. For children's wear,特别注意 small parts safety and attachment strength. Including physical swatches or approved supplier information for key components prevents substitution with non-compliant alternatives during production.

What Construction Details Ensure Quality Execution?

Construction specifications translate design into manufacturing instructions, detailing how each component should be assembled to achieve the desired quality, durability, and appearance.

Children's wear construction requires attention to safety, comfort, and durability considerations beyond standard apparel requirements.

What Stitch and Seam Specifications Matter?

Specify stitch type (lockstitch, chainstitch, overlock), stitches per inch (SPI), seam type (French, flatlock, superimposed), and seam allowance for every construction point. Children's wear often requires higher stitch densities for durability and specific seam types to prevent irritation. Our manufacturing guidelines include children's-specific construction standards that exceed general apparel requirements, particularly for areas experiencing high stress during play and movement.

How Should Reinforcement and Finishing Be Detailed?

Specify reinforcement methods like bar tacks at stress points, stay tapes in shoulder seams, and elastic applications. Detail finishing techniques including edge treatments, hemming methods, and interior finishing that ensures comfort against sensitive skin. For children's wear,特别注意 eliminating potential irritation points through techniques like tagless labeling, covered seams, and smooth interior finishes. These details significantly impact wearability for young children.

What Compliance Information Is Required?

Children's product compliance represents a non-negotiable tech pack component, detailing all safety standards, testing requirements, and certification needs specific to the target market.

Regulatory requirements vary by country and age group, making comprehensive compliance specifications essential for legal market entry and consumer safety.

What Safety Standards Must Be Referenced?

Clearly identify all applicable safety standards based on target market and garment type. For US markets, this typically includes CPSIA compliance, flammability standards (especially for sleepwear), and small parts regulations. European markets require CE marking, EN71 compliance, and REACH chemical restrictions. Reference specific standard numbers and versions to ensure manufacturers use current requirements rather than outdated references.

What Testing and Documentation Is Required?

Specify required third-party testing, certification documentation, and label requirements including content, placement, and permanence. Detail any specific tracking or documentation needs like batch numbering or lot identification. For children's wear,特别注意 that all components—not just major fabrics—meet safety standards, including threads, elastics, and trims. Our compliance team verifies that all testing requirements are clearly specified before production begins.

Conclusion

A comprehensive kids clothing tech pack serves as the critical bridge between design vision and manufactured reality, ensuring all parties share identical understanding of every garment detail. The most effective tech packs balance comprehensive detail with clear organization, providing manufacturers with all necessary information to execute designs accurately while meeting quality and safety standards.

At Shanghai Fumao Clothing, we've developed tech pack templates and review processes that help brands create complete specifications, drawing on our decades of experience manufacturing children's wear for American and European markets. If you're developing children's wear and need assistance creating or reviewing your tech packs, contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how our technical expertise can support your production success.