If you're manufacturing or sourcing children's clothing, you've likely encountered the complex web of safety standards that vary significantly between baby and toddler apparel. Understanding these distinctions isn't just about compliance—it's about protecting vulnerable wearers during their most rapid developmental stages. At Fumao Clothing, our specialized production lines for different age groups have given us firsthand insight into why these standards diverge and how they impact design and manufacturing decisions.

Safety standards differ between baby and toddler clothing due to developmental variations, mobility differences, and distinct risk profiles that require age-specific protection approaches. These distinctions reflect the unique vulnerabilities of each developmental stage, from the complete dependency of infancy to the increasing independence and mobility of toddlerhood.

The regulatory framework recognizes that a newborn's needs and risks differ dramatically from those of an active three-year-old. These differences manifest in fabric requirements, design elements, and testing protocols that ensure appropriate protection for each developmental stage.

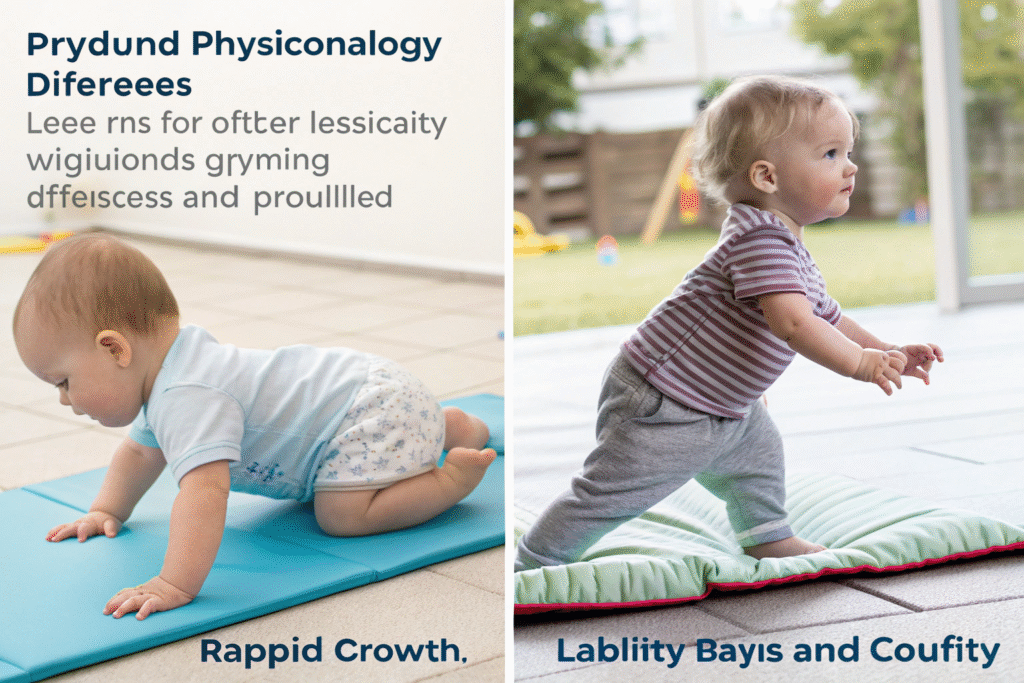

How Do Developmental Differences Drive Safety Requirements?

The profound physiological and developmental differences between babies and toddlers create distinct safety priorities that regulations must address appropriately.

Babies experience rapid growth but limited mobility, while toddlers develop increasing coordination alongside boundless curiosity. These developmental realities directly influence which safety aspects require emphasis in clothing for each age group.

Why Are Baby's Physiological Vulnerabilities Unique?

Newborns and young infants have underdeveloped respiratory systems, fragile skin, and limited ability to reposition themselves or remove clothing that causes discomfort or danger. These vulnerabilities necessitate extreme attention to breathability, non-toxic materials, and designs that prevent facial covering. The American Academy of Pediatrics emphasizes that婴儿 clothing must prioritize protection against overheating and suffocation risks above all other considerations, as these represent the most significant threats to infant safety.

How Does Toddler Mobility Change Risk Calculations?

Toddlers' increasing mobility introduces new hazards like falls, entanglement, and access to dangerous areas through climbing. Clothing must support safe movement while preventing new risks created by this developing independence. Our manufacturing protocols for toddler wear specifically address mobility safety through reinforced construction, non-slip features where appropriate, and designs that don't impede movement or create tripping hazards during this active developmental stage.

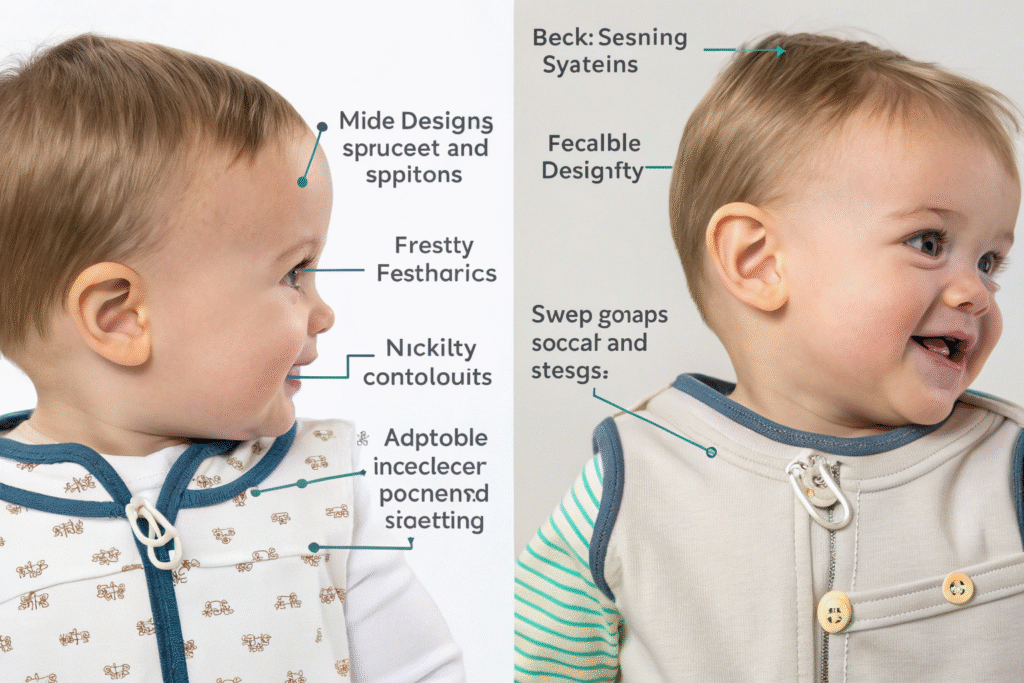

What Design Element Variations Address Age-Specific Risks?

Specific design requirements differ substantially between baby and toddler clothing, reflecting their distinct activities, capabilities, and risk profiles.

From neck openings to fastening systems, each design element must address the unique safety considerations of the intended wearer's developmental stage while maintaining functionality and comfort.

Why Do Neck Openings and Fastenings Differ?

Baby clothing typically features envelope necks, snap crotches, and zipper guards to facilitate dressing and prevent pinching, while toddler clothing may incorporate more traditional necklines and fastening systems as children develop coordination. These distinctions reflect practical dressing challenges and safety considerations at each stage. Our technical designers follow patternmaking standards that specify neck opening measurements, fastening placements, and ease allowances appropriate for each age category's physical proportions and capabilities.

How Do Sleeve and Leg Construction Requirements Vary?

Baby wear often includes integrated mittens and footed designs to prevent scratching and provide warmth without loose elements, while toddler clothing typically features separate mittens and socks as children develop more coordinated hand and foot use. These construction differences acknowledge developing motor skills and changing safety priorities. The transition from footed sleepers to separate footwear in toddler clothing represents one of the most visible manifestations of this developmental progression in safety standards.

What Fabric and Material Standards Differ Between Age Groups?

Material requirements evolve significantly from infancy through toddlerhood, reflecting changing skin sensitivity, activity levels, and safety priorities.

The same fabric that's perfectly safe for a toddler might be inappropriate for a newborn due to differences in skin permeability, temperature regulation, and contact time during sleep periods.

Why Are Baby Fabric Standards More Stringent?

Infant skin is more permeable, thinner, and more susceptible to irritation and chemical absorption than adult or even toddler skin. This necessitates stricter limits on chemical residues, dyes, and finishing treatments in baby clothing. Our fabric sourcing for baby wear follows OEKO-TEX Standard 100 certification requirements specifically for products intended for infants, which imposes stricter limits on substance concentrations than standards for older children's clothing.

How Do Durability Requirements Evolve with Age?

While baby clothing prioritizes softness and chemical safety, toddler clothing must withstand increased abrasion, repeated washing, and more vigorous activity. This evolution reflects changing usage patterns as children become more active and independent. Our quality testing protocols apply different dubility standards for baby versus toddler garments, recognizing that the same fabric might need to meet different performance requirements based on the wearer's age and expected activity level.

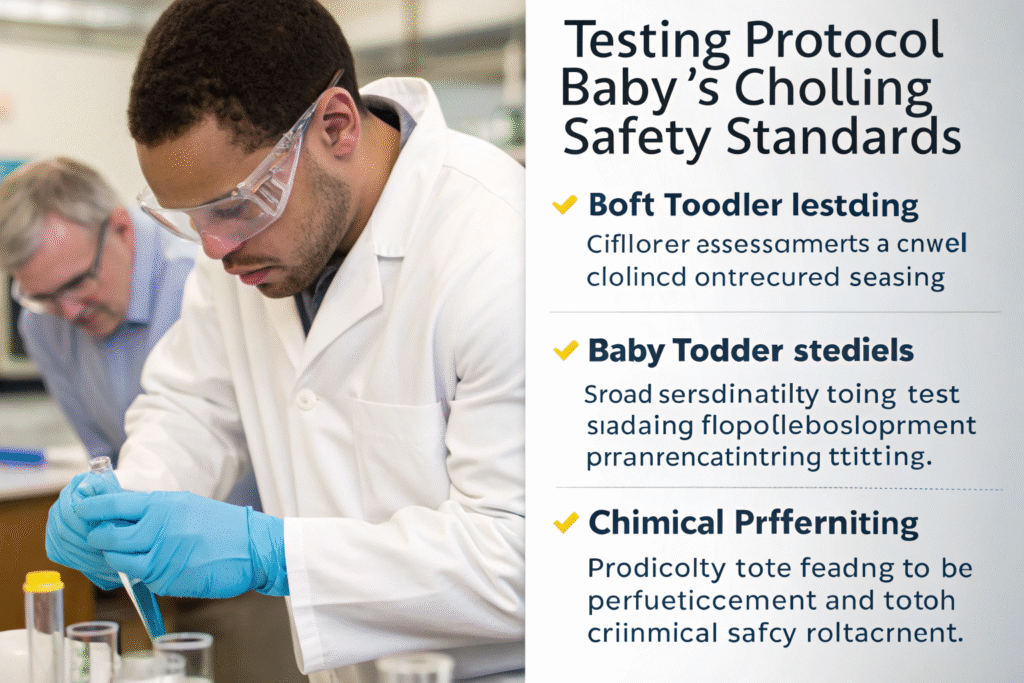

How Do Testing Protocols Reflect Developmental Differences?

Safety testing methodologies vary substantially between baby and toddler clothing, simulating the distinct risks and usage patterns relevant to each developmental stage.

From small parts testing to flammability requirements, verification protocols acknowledge that a hazard for one age group may present minimal risk to another.

Why Does Small Parts Testing Intensity Vary?

Small parts regulations are particularly stringent for children under three years due to mouthing behaviors and increased choking risks. However, testing protocols may differ even within this age range, recognizing that a newborn's capabilities differ significantly from a two-year-old's. Our quality assurance team follows CPSC guidelines that specify different small parts testing methodologies and acceptance criteria for various age categories within the 0-3 year range.

How Do Flammability Standards Address Different Risks?

Flammability standards recognize that babies spend more time sleeping while toddlers are more active and mobile near potential ignition sources. This difference influences both testing methods and performance requirements. Sleepwear for infants typically must meet stricter flammability standards than daytime wear for toddlers, reflecting the increased risk during sleep periods when supervision may be reduced.

Conclusion

The distinction between baby and toddler clothing safety standards represents a thoughtful regulatory response to profound developmental differences that create unique vulnerabilities and risks at each stage. Understanding these distinctions enables manufacturers, brands, and retailers to create appropriately safe products while helping parents make informed purchasing decisions.

At Shanghai Fumao Clothing, we maintain separate production protocols and quality assurance systems for our baby and toddler clothing lines, recognizing that safety cannot follow a one-size-fits-all approach across developmental stages. If you're developing children's wear that requires age-appropriate safety compliance, contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how our specialized manufacturing expertise can ensure your products meet the precise safety standards for your target age group.