Navigating the complex landscape of Consumer Product Safety Commission (CPSC) requirements is essential for any children's clothing brand operating in the United States. Compliance isn't just about avoiding penalties—it's about ensuring child safety and building trust with parents who increasingly verify safety credentials before purchasing.

To ensure your kids clothing meets CPSC requirements, you must understand and implement regulations for flammability, lead and phthalate content, small parts, drawstrings, and tracking labels, while maintaining thorough documentation and conducting regular compliance audits. This comprehensive approach protects both children and your business from safety risks.

The CPSC maintains stringent standards specifically for children's products, with requirements that often exceed those for adult apparel. Understanding these regulations during the design phase—rather than as an afterthought—prevents costly reengineering and potential recalls. Let's examine the specific strategies for maintaining full CPSC compliance throughout your product development process.

What are the key CPSC standards for children's clothing?

Understanding the specific regulations that apply to children's clothing provides the foundation for an effective compliance strategy. These standards address various safety hazards from chemical exposure to physical dangers.

The key CPSC standards for children's clothing include flammability regulations for sleepwear, lead and phthalate content limits under CPSIA, small parts requirements for young children, drawstring guidelines, and tracking label mandates. Each standard addresses specific risks associated with children's products.

How do flammability standards vary by clothing type?

The CPSC maintains specific flammability standards for different types of children's sleepwear under 16 CFR Parts 1615 and 1616. These regulations require that sleepwear for children sizes 0-14 must either be made from inherently flame-resistant fabrics or pass rigorous vertical flame tests. Importantly, tight-fitting sleepwear has different requirements than loose-fitting styles, recognizing that closer-fitting garments present less fire risk. Daywear for children falls under the general wearing apparel flammability standards (16 CFR Part 1610), which are less stringent but still mandatory. Understanding these distinctions prevents misclassification that could lead to non-compliant production.

What are the CPSIA chemical requirements?

The Consumer Product Safety Improvement Act (CPSIA) sets strict limits on lead content (100 ppm in substrates) and certain phthalates (DEHP, DBP, BBP permanently banned at 1000 ppm; DINP, DIDP, DnHP temporarily banned in children's toys and childcare articles). These restrictions apply to all components of children's products, including fabrics, threads, prints, dyes, and trims. For children's clothing, this means every element—from buttons to zippers to screen prints—must be verified for compliance. The most thorough approach involves obtaining material certifications from suppliers and conducting periodic testing to verify ongoing compliance.

How can you implement effective testing protocols?

Regular, systematic testing provides the evidence needed to demonstrate compliance and identify potential issues before products reach consumers. A strategic testing approach balances thoroughness with practical considerations.

Implement effective testing protocols by establishing testing schedules based on product risk, using CPSC-accepted third-party laboratories, maintaining material certification records, and conducting production audits to ensure consistency. This systematic approach catches compliance issues early.

When should you conduct compliance testing?

The most effective testing strategy involves multiple testing stages: material testing during development, pre-production testing of finished prototypes, and production testing of random samples from manufacturing runs. For children's clothing, high-risk elements like sleepwear flammability require more frequent testing than general daywear requirements. Additionally, any material or component changes should trigger re-testing, even mid-season. Many compliant brands establish a testing calendar that aligns with their production schedule, ensuring testing occurs at optimal points without delaying production timelines.

How do you select appropriate testing laboratories?

CPSC compliance requires testing by CPSC-accepted laboratories specifically for children's products. These laboratories must be accredited to ISO/IEC 17025 and specifically accepted by the CPSC for each applicable test method. When selecting a laboratory, verify their specific scope of accreditation includes the standards you need tested. Additionally, consider laboratories with expertise in textile testing specifically, as they'll better understand nuances like fabric preparation, conditioning, and testing methodology that can impact results. Building relationships with qualified laboratories streamlines the testing process and improves communication when questions arise.

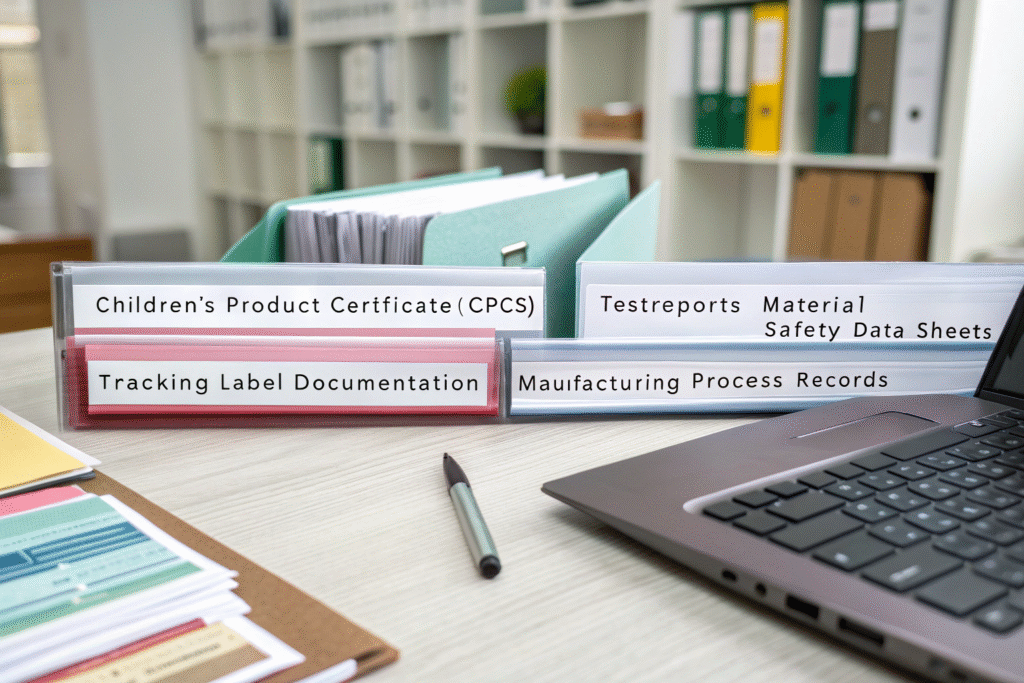

What documentation demonstrates CPSC compliance?

Proper documentation provides the evidence needed to verify compliance during CPSC inspections and builds consumer trust through transparency. Maintaining organized, accessible records is as important as the compliance itself.

Documentation that demonstrates CPSC compliance includes Children's Product Certificates (CPCs), test reports from accredited laboratories, material safety data sheets, tracking label documentation, and manufacturing process records. This documentation must be maintained for years after products are sold.

What should a Children's Product Certificate include?

The Children's Product Certificate (CPC) is a required document that must accompany every children's product imported or manufactured for the US market. A complete CPC must identify the product, list all applicable CPSC safety rules, provide contact information for the importer or domestic manufacturer, include maintenance of testing records, and list the date and place of manufacture. The CPC must be based on testing from a CPSC-accepted laboratory and issued by the domestic manufacturer or importer. Many brands create template CPCs that can be efficiently completed for each product while ensuring all required elements are included.

How long must compliance records be maintained?

CPSC regulations require that supporting testing documentation be maintained for five years from the date of importation or manufacture. This includes detailed test reports, material certifications, and manufacturing records that demonstrate how compliance was achieved and verified. The most organized approaches use digital document management systems that ensure records remain accessible throughout this retention period, even as staff changes occur. Proper recordkeeping not only satisfies regulatory requirements but also provides valuable reference material when developing new products with similar components or materials.

How can you address specific hazard requirements?

Different clothing components present unique compliance challenges that require targeted strategies. Understanding these specific hazards allows for proactive compliance during design and production.

Address specific hazard requirements by implementing drawstring restrictions according to CPSC guidelines, ensuring small parts compliance for young children's clothing, selecting compliant trims and closures, and verifying labeling meets all requirements. This component-specific approach catches potential issues early.

What are the drawstring requirements for children's clothing?

While not a formal regulation, the CPSC has issued guidelines for drawstrings in children's upper outerwear that most retailers treat as mandatory. These guidelines prohibit drawstrings at the hood and neck area in sizes 2T-12, and restrict drawstring length at the bottom in sizes 2T-16. The guidelines also specify that toggles and knots must break away under specific force requirements. Many brands extend these guidelines to all children's clothing, not just upper outerwear, to ensure comprehensive safety. During design, consider alternative closure systems like snaps, magnets, or elastic that avoid drawstring hazards entirely.

How do small parts regulations affect design choices?

For clothing intended for children under 3 years, small parts regulations require that no components can fit entirely into a small parts cylinder (approximately the size of a toddler's throat). This affects button selection, appliqué design, trim choices, and decorative elements. During design review, use a small parts cylinder to test all components, recognizing that wear and tear during use could create small parts from originally secure elements. The most cautious approach designs clothing for this age group without any removable components, using instead printed designs, embroidered details, and securely attached elements that cannot detach even with reasonable force.

Conclusion

Ensuring your kids clothing meets CPSC requirements requires a systematic approach that integrates compliance considerations throughout the product development process—from initial design to final production. By understanding specific standards, implementing rigorous testing, maintaining thorough documentation, and addressing component-specific hazards, brands can confidently bring safe products to market while building trust with safety-conscious parents.

The most successful compliance strategies view these requirements not as burdensome regulations but as frameworks for creating safer products. This mindset shift transforms compliance from a cost center to a value proposition that differentiates brands in a competitive market.

Remember that CPSC requirements continue to evolve, with new regulations and updated standards emerging regularly. Maintaining compliance requires ongoing vigilance, continuous education, and proactive adaptation to regulatory changes. Brands that establish robust compliance systems position themselves for long-term success while ensuring the safety of their youngest customers.

Ultimately, CPSC compliance represents both a legal obligation and an ethical commitment to protecting children. The brands that embrace this dual responsibility will build stronger reputations and more sustainable businesses in the children's wear market.

Ready to ensure your kids clothing meets all CPSC requirements? Our expertise includes comprehensive compliance strategies, testing coordination, documentation management, and design guidance that addresses regulatory requirements from concept through production. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can help you navigate CPSC compliance with confidence.