As a children's clothing manufacturer operating from China for decades, I've witnessed firsthand how Chinese manufacturers have transformed from low-cost producers to market leaders in the global kids wear industry. This dominance isn't accidental—it's the result of strategic evolution and systemic advantages that have developed over thirty years of focused investment and learning.

Chinese manufacturers dominate the kids wear market through an unparalleled combination of scale efficiency, vertical integration, quality improvement, and supply chain reliability. This dominance stems from complete ecosystem development that offers international brands competitive pricing, flexible order quantities, consistent quality control, and reliable delivery timelines that manufacturers in other regions struggle to match.

The evolution of China's children's wear manufacturing sector represents one of the most significant shifts in global textile production, moving from basic assembly to comprehensive partnership with international brands. Understanding the factors behind this dominance helps brands make informed sourcing decisions.

What competitive advantages do Chinese manufacturers offer?

Chinese manufacturers have developed a comprehensive set of competitive advantages that extend far beyond simple cost savings. These systemic strengths create a manufacturing ecosystem that delivers value at multiple levels for international children's wear brands.

The most significant advantages combine scale efficiencies with increasingly sophisticated technical capabilities and supply chain integration. This multi-layered approach allows Chinese manufacturers to solve complex production challenges while maintaining competitive pricing and reliable delivery.

How does vertical integration reduce costs and lead times?

Vertical integration represents one of China's most powerful advantages in children's wear manufacturing. Many Chinese manufacturers control multiple stages of production—from spinning yarn and weaving fabric to cutting, sewing, and finishing—within connected operations or tightly coordinated supplier networks. This integration eliminates multiple layers of markup and reduces coordination friction between different production stages. Fabric and trim sourcing happens within the same industrial ecosystems where manufacturing occurs, dramatically reducing material transportation time and costs. Production planning can be synchronized across manufacturing stages, minimizing bottlenecks and inventory buildup. Quality control can be implemented at each production phase rather than only at final inspection. This comprehensive control over the supply chain creates efficiencies that vertically integrated manufacturers can translate into both cost savings and timeline reliability for international brands.

What technical capabilities set Chinese manufacturers apart?

Chinese manufacturers have developed specialized technical capabilities specifically for the children's wear market. Advanced printing technologies including digital, sublimation, and silicone printing allow for intricate designs that comply with international safety standards. Expertise in specialized construction techniques like flatlock stitching for comfort, reinforced seams for durability, and innovative closure systems for ease of dressing meet both functional and safety requirements. Sophisticated pattern-making specifically for children's proportions ensures better fit across age groups. Technical fabric development capabilities create customized materials with specific performance characteristics like moisture-wicking, UV protection, and stretch recovery. Additionally, comprehensive testing laboratories within manufacturing facilities ensure compliance with international standards like OEKO-TEX Standard 100 and CPSIA before shipment. These technical capabilities enable Chinese manufacturers to produce increasingly sophisticated children's wear that meets both design and safety requirements.

How has Chinese manufacturing evolved beyond low cost?

The perception of Chinese manufacturing as solely focused on low-cost production has become outdated. While competitive pricing remains important, Chinese manufacturers have strategically moved up the value chain to offer advantages that extend far beyond initial price points.

This evolution represents a deliberate transition from competing on cost alone to competing on value, quality, innovation, and reliability. International children's wear brands now partner with Chinese manufacturers for capabilities that didn't exist in China a decade ago.

What quality improvements have been implemented?

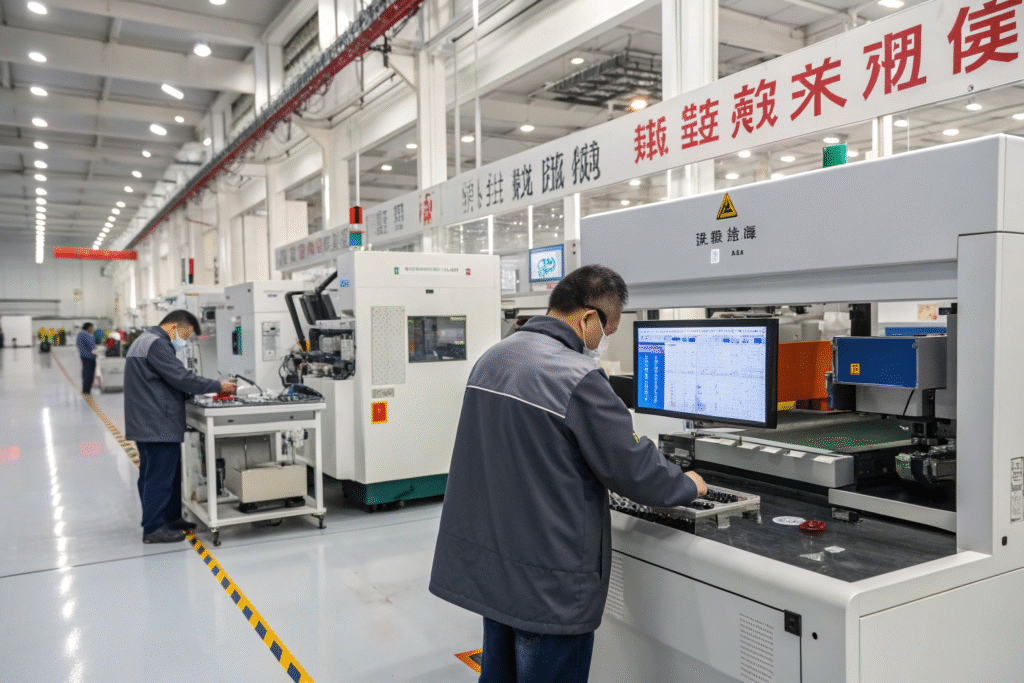

Chinese manufacturers have made substantial investments in quality management systems that rival those found in traditional manufacturing regions. Implementation of automated cutting systems has improved precision and consistency across production runs. Computerized sewing equipment with programmed stitch patterns ensures uniform quality and reduces human error. Advanced washing and finishing technologies create specific fabric hands and performance characteristics. Statistical process control methods monitor production quality in real-time, identifying issues before they affect significant quantities. Investment in testing laboratories with equipment for color fastness, fabric strength, and chemical compliance provides objective quality verification. Additionally, many factories have adopted quality standards like ISO 9001, creating systematic approaches to quality management rather than relying solely on final inspection. These improvements have positioned Chinese manufacturers as quality leaders rather than simply low-cost alternatives.

How have Chinese manufacturers adapted to market demands?

Chinese manufacturers have demonstrated remarkable adaptability in responding to evolving international market demands. The development of flexible manufacturing systems allows efficient production of smaller batches with quicker turnaround times, responding to fast-fashion and test-and-react business models. Implementation of comprehensive compliance systems addresses growing consumer concerns about safety, ethics, and sustainability. Rapid adoption of digital technologies enables seamless communication and collaboration with international partners across time zones. Development of specialized expertise in niche categories like performance wear, organic clothing, or adaptive wear for children with special needs demonstrates market-responsive specialization. Additionally, many manufacturers have evolved from pure production into design partnership, offering trend forecasting, material development, and design assistance that adds value beyond basic manufacturing. This adaptability has been crucial in maintaining China's position as manufacturing preferences have evolved.

What supply chain factors contribute to China's dominance?

China's manufacturing dominance in children's wear is supported by a supply chain ecosystem that has developed over decades and remains difficult to replicate elsewhere. This ecosystem provides efficiencies and capabilities that extend far beyond the factory walls.

The comprehensive nature of China's textile and apparel supply chain creates natural advantages that manufacturers in other regions struggle to match. These systemic strengths have been built through consistent investment and scale that creates barriers to entry for emerging manufacturing regions.

| Supply Chain Factor | Chinese Advantage | Impact on Kids Wear Production |

|---|---|---|

| Raw Material Access | Complete textile production ecosystem | Faster fabric sourcing, better material pricing |

| Component Availability | Extensive trim and accessory industries | One-stop sourcing, reduced lead times |

| Skilled Labor Pool | Generations of technical expertise | Complex construction, quality execution |

| Infrastructure | Modern ports, roads, and logistics | Reliable shipping, cost-effective transportation |

| Manufacturing Density | Geographic concentration of specialists | Efficient coordination between production stages |

How does manufacturing clustering create efficiency?

Manufacturing clustering in specific regions of China creates remarkable efficiencies that benefit children's wear production. The Pearl River Delta and Yangtze River Delta regions contain concentrated ecosystems of factories, material suppliers, and service providers specifically focused on apparel manufacturing. This geographic concentration allows for rapid movement of materials between production stages, reducing transportation time and costs. Specialization within clusters means manufacturers can focus on their core competencies while easily accessing partners for complementary processes. Knowledge sharing within clusters accelerates innovation and problem-solving as best practices diffuse quickly between neighboring facilities. Labor markets in these regions contain experienced workers with specific technical skills relevant to children's wear production. Additionally, service providers like freight forwarders, inspection companies, and certification bodies have established specialized operations within these clusters, creating a comprehensive support ecosystem. This clustering effect creates efficiencies that dispersed manufacturing locations cannot easily replicate.

What logistics infrastructure supports reliable delivery?

China's investment in world-class logistics infrastructure ensures reliable delivery timelines that support the fast-paced cycles of children's fashion. Modern container ports with high-volume capacity and frequent sailings to all major markets provide shipping options and flexibility. Extensive highway and rail networks connect manufacturing regions to ports efficiently, reducing domestic transit time. Integrated logistics services offer comprehensive solutions from factory to destination warehouse, including customs clearance and final mile delivery. Digital tracking systems provide real-time visibility into shipment status throughout the transportation process. Additionally, manufacturers have developed expertise in navigating export procedures and documentation requirements, streamlining the shipping process for international partners. This logistics capability, combined with manufacturing reliability, enables Chinese manufacturers to offer and maintain delivery timelines that support the seasonal nature of children's fashion retail.

How do Chinese manufacturers maintain price competitiveness?

While Chinese manufacturing is no longer the lowest-cost option globally, it maintains remarkable price competitiveness given the quality and services provided. This sustained competitiveness stems from multiple factors that collectively create value beyond initial price points.

The evolution of Chinese manufacturing has shifted from competing solely on price to competing on total value, which includes quality, reliability, and comprehensive service alongside competitive pricing.

What economies of scale advantage Chinese production?

Chinese manufacturers achieve significant economies of scale that maintain price competitiveness despite rising costs. Large production volumes spread fixed costs like equipment, facilities, and management across more units, reducing per-unit costs. Bulk purchasing of raw materials provides pricing advantages that smaller manufacturers cannot access. High utilization rates of production capacity ensure manufacturing efficiency and cost absorption. Investment in automation and advanced machinery, while capital-intensive, reduces long-term production costs through higher efficiency and lower labor requirements. Additionally, the concentration of manufacturing within ecosystems creates scale advantages in supporting services like logistics, maintenance, and technical support. These scale advantages allow Chinese manufacturers to maintain competitive pricing while improving quality and services, creating a value proposition that remains compelling despite rising wages and other costs.

How has automation affected cost structure?

Strategic automation has transformed the cost structure of Chinese children's wear manufacturing while maintaining competitiveness. Automated cutting systems have reduced fabric waste by 5-15% while improving cutting precision and speed. Computerized sewing machines have increased stitching consistency and reduced training time for specialized operations. Automated packaging and labeling systems have streamlined final production stages while reducing labor requirements. Robotics in material handling has improved efficiency in moving goods between production stages. Importantly, Chinese manufacturers have typically implemented automation selectively where it provides the greatest return rather than comprehensive automation, maintaining flexibility while controlling costs. This balanced approach to automation has allowed Chinese manufacturers to offset rising labor costs while improving quality and maintaining competitive pricing for international brands.

Conclusion

Chinese manufacturers dominate the global kids wear market through a powerful combination of scale, supply chain integration, continuous improvement, and adaptive capabilities that have evolved over decades. This dominance stems not from any single factor but from a comprehensive manufacturing ecosystem that offers international brands competitive pricing, reliable quality, flexible production, and dependable delivery. While manufacturing costs have risen in China compared to emerging alternatives, the total value proposition—combining cost with quality, reliability, and comprehensive service—remains compelling for children's wear brands operating in competitive global markets.

At Fumao Clothing, our experience mirrors this broader evolution—from focusing on cost competitiveness to developing specialized expertise in children's wear manufacturing for American and European brands. Our investments in vertical integration, quality management, and sustainable practices reflect the maturation of Chinese manufacturing capabilities. If you're looking for a manufacturing partner that combines Chinese manufacturing advantages with dedicated expertise in children's wear, contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can bring efficiency, quality, and reliability to your children's wear production.