Building a children's clothing brand with safety as the core foundation requires more than just good intentions—it demands systematic planning, deep industry knowledge, and unwavering commitment. As a manufacturer who has helped launch numerous successful children's brands, I've seen how safety-focused companies not only protect children but also build unparalleled trust with parents.

Building a kids clothing brand that prioritizes safety involves implementing rigorous material testing protocols, designing with hazard prevention in mind, establishing transparent supply chain controls, and creating comprehensive safety documentation. This approach requires going beyond basic compliance to embed safety considerations into every aspect of your business, from initial design concepts to final product delivery.

Safety cannot be an afterthought; it must be the foundation upon which every other brand element is built, creating clothing that protects children while allowing them the freedom to play and explore.

What Are the Fundamental Safety Standards Every Brand Must Know?

Understanding and implementing safety standards is non-negotiable for any serious children's clothing brand. These regulations exist because they address real risks that have caused harm to children in the past.

Compliance should be your baseline, not your ultimate goal—the most successful safety-focused brands often exceed regulatory requirements.

Which Regulatory Standards Are Mandatory?

In the US market, CPSC children's apparel regulations form the legal foundation for safety compliance. These include flammability standards for sleepwear, lead content limits, and small parts regulations that prevent choking hazards. Additionally, the Textile and Wool Acts govern fiber content labeling and care instruction requirements. Understanding these regulations is crucial because ignorance is never an acceptable defense when children's safety is concerned.

How Do Voluntary Certifications Enhance Safety?

Beyond mandatory regulations, voluntary certifications demonstrate your brand's commitment to exceeding basic requirements. The OEKO-TEX Standard 100 certification tests for harmful substances beyond legal requirements, while GOTS (Global Organic Textile Standard) ensures organic status and environmental responsibility. These certifications provide third-party validation of your safety claims, giving parents confidence that you've invested in independent verification of your product safety.

| Safety Area | Mandatory Standards | Voluntary Certifications | Key Requirements |

|---|---|---|---|

| Chemical Safety | CPSIA lead/phthalate limits | OEKO-TEX Standard 100 | Testing for harmful substances |

| Flammability | CPSC sleepwear standards | - | Vertical flame test compliance |

| Physical Hazards | Small parts regulations | - | Secure attachments, no choking hazards |

| Material Quality | Fiber content labeling | GOTS, GRS | Organic content, recycled materials |

How to Design Clothing with Built-in Safety Features?

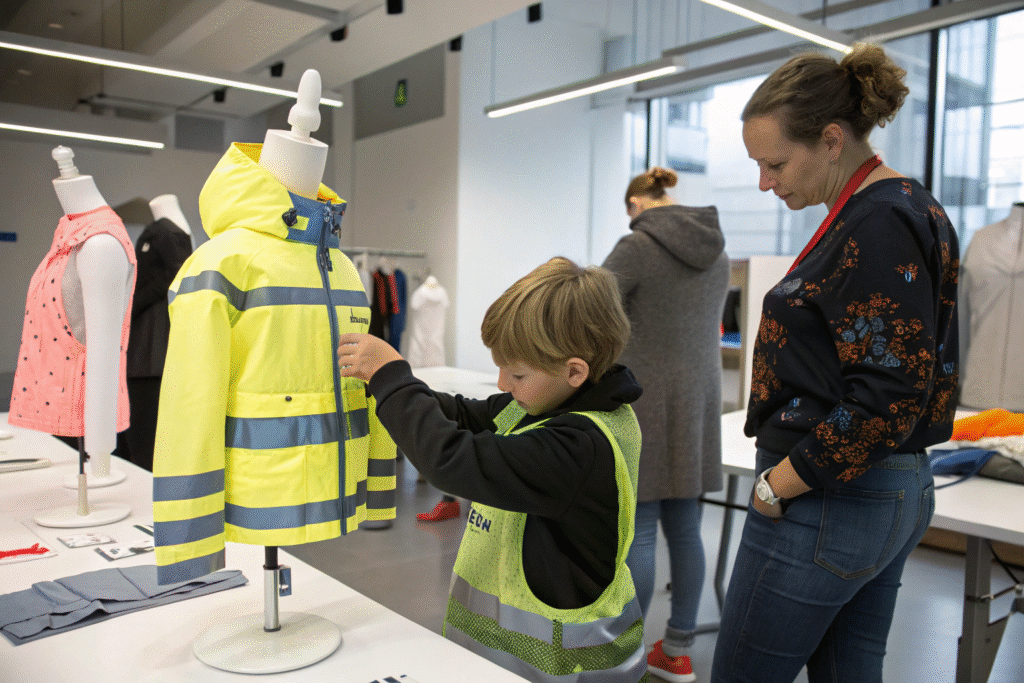

Safety-focused design anticipates potential hazards and eliminates them through thoughtful construction and feature selection. This proactive approach prevents problems rather than reacting to them after they occur.

Great safety design is invisible—it protects without restricting comfort or style, creating clothing that works harmoniously with children's natural movements and behaviors.

What Design Elements Prevent Physical Hazards?

Every design decision should consider potential risks. Secure attachment methods for buttons, snaps, and decorative elements prevent choking hazards. Avoiding drawstrings around the neck area eliminates strangulation risks. Using flatlock seams instead of raised seams prevents skin irritation. At our factory, we've developed specialized techniques for securing common hazard points, such as bar-tacking stress points and using reinforced stitching for all attachments that could potentially loosen during active wear.

How Does Fabric Selection Impact Safety?

Fabric choices directly affect both comfort and safety. Breathable natural fibers reduce overheating risk, while stretch fabrics accommodate movement without restriction. For sleepwear, selecting inherently flame-resistant fabrics or properly treated materials is crucial. We recommend testing fabrics for colorfastness to prevent skin exposure to dyes, and selecting materials with appropriate weight and structure that won't cause tripping or entanglement hazards.

What Supply Chain Controls Ensure Consistent Safety?

Your brand's safety commitment is only as strong as your weakest supply chain link. Implementing rigorous controls throughout your manufacturing process ensures consistency and prevents compromises that could undermine your safety standards.

Transparency and verification at every production stage create the foundation for trustworthy safety assurance.

How to Vet Manufacturing Partners for Safety?

Selecting the right manufacturing partner is your most important safety decision. Look for factories with proven track records in children's product manufacturing and established quality control systems. Verify their understanding of relevant safety standards and request evidence of compliance testing for previous clients. During factory visits, observe their attention to detail, worker training, and commitment to documentation. The best partners will welcome your safety scrutiny and demonstrate their own commitment to exceeding requirements.

What Testing Protocols Are Essential?

Regular, comprehensive testing provides objective safety verification. Third-party testing should cover physical safety (small parts, sharp points), chemical compliance (lead, phthalates), and flammability where applicable. Establish testing schedules that include pre-production material checks, in-process production audits, and final random sample testing. Document every test result and maintain records for at least three years, as this documentation may be crucial if safety questions arise later.

How to Communicate Safety to Parents Effectively?

Safety features have limited value if parents don't understand or trust them. Clear, honest communication builds the confidence that transforms safety investments into brand loyalty.

Your safety messaging should educate without alarming, demonstrating your expertise while respecting parents' intelligence and concern for their children's wellbeing.

What Labeling and Packaging Communicate Safety?

Your product labels and packaging provide crucial safety information. Clear care labels help maintain safety features, while certification logos instantly communicate your compliance with recognized standards. Consider adding simple explanations of key safety features, such as "breakaway closures for safety" or "OEKO-TEX certified free from harmful substances." This transparent communication helps parents understand the value behind your safety investments.

How Does Marketing Build Safety Trust?

Your marketing should highlight safety without making it seem like an extraordinary claim. Authentic storytelling about your safety philosophy, behind-the-scenes looks at your testing processes, and educational content about children's product safety all build credibility. Avoid overpromising or using fear-based marketing—instead, position safety as a fundamental right that every child deserves and every parent should expect from quality children's clothing.

Conclusion

Building a children's clothing brand that genuinely prioritizes safety requires comprehensive planning, rigorous implementation, and transparent communication. By embedding safety considerations into your design process, supply chain management, and brand messaging, you create products that protect children while building parent trust that translates into long-term brand loyalty. The investment in safety excellence differentiates your brand in a crowded market and creates lasting value for all stakeholders.

At Shanghai Fumao Clothing, we've dedicated our manufacturing expertise to helping brands implement the highest safety standards without compromising on style or affordability. Our experience with safety certifications, testing protocols, and hazard-preventive design can help you build a brand that parents trust implicitly. If you're ready to create children's clothing where safety is the foundation, not an afterthought, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build something safe, beautiful, and enduring together.