A well-defined production workflow serves as the operational backbone of any successful garment factory, directly impacting efficiency, quality control, and client satisfaction. As manufacturers who have refined our processes over decades, we understand how workflow clarity separates high-performing factories from those struggling with delays, quality issues, and cost overruns.

A clear production workflow is vital for garment factories because it establishes standardized processes that ensure consistent quality, enables accurate production planning and timeline management, facilitates effective resource allocation, and provides transparency for both internal teams and clients. This operational clarity transforms chaotic manufacturing into a predictable, repeatable system that can scale efficiently while maintaining quality standards. Without this foundation, factories face constant firefighting, missed deadlines, and inconsistent output that damages reputation and profitability.

How Does Workflow Clarity Impact Production Efficiency?

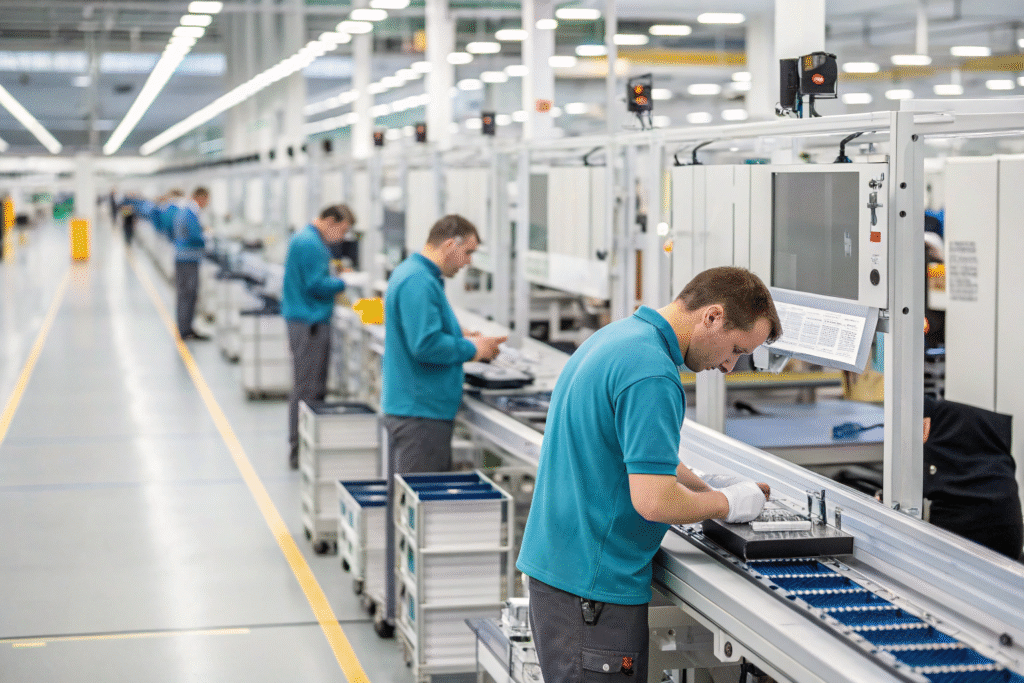

A clearly defined workflow eliminates confusion, reduces bottlenecks, and creates a smooth manufacturing rhythm that maximizes throughput while minimizing wasted time and resources.

When every team member understands their specific responsibilities, the sequence of operations, and quality checkpoints, work flows seamlessly between departments without unnecessary delays or handoff confusion. This operational efficiency directly translates to faster turnaround times, lower production costs, and increased capacity—critical competitive advantages in the fast-paced fashion industry where timing often determines profitability.

What Are the Direct Benefits of Standardized Processes?

Standardized processes create predictability that benefits every aspect of factory operations. According to the American Apparel & Footwear Association, factories with documented standard operating procedures (SOPs) experience 25-40% higher productivity than those relying on tribal knowledge. Standardization reduces training time for new employees, minimizes errors from inconsistent methods, and enables accurate capacity planning. For each production stage—from fabric inspection and pattern cutting to sewing and finishing—clear standards ensure every operator performs tasks the same optimized way, creating consistent results regardless of which team member completes the work.

How Does Workflow Visibility Prevent Bottlenecks?

Visible workflow systems allow managers to identify and address constraints before they cause significant delays. When production stages are clearly defined and tracked, bottlenecks become immediately apparent, enabling proactive resource reallocation. The Theory of Constraints methodology demonstrates that improving flow at constraint points increases overall system throughput more than optimizing individual steps. In garment manufacturing, this might mean cross-training operators to support overloaded sewing stations or adjusting cutting schedules to ensure assembly lines never wait for materials. This systemic visibility transforms production from a series of disconnected tasks into a coordinated, flowing system.

How Does Workflow Standardization Ensure Consistent Quality?

Consistent quality requires repeatable processes rather than heroic efforts by individual workers. A clear workflow embeds quality checkpoints throughout production rather than relying solely on final inspection.

Quality control integrated into each production stage catches defects early when they're less costly to fix and prevents the compounding of errors through subsequent operations. This proactive approach to quality significantly reduces rework rates, material waste, and the frustration of discovering major issues at final inspection when correction is most difficult and expensive.

Why Are In-Process Quality Checks More Effective Than Final Inspection?

Catching defects at their source prevents the waste of processing flawed garments through subsequent stages. Research from the American Society for Quality shows that defects detected during production cost 5-10 times less to correct than those found at final inspection. A clear workflow specifies exactly when and how quality checks should occur—after cutting, during sewing, at assembly completion—with defined acceptance criteria at each stage. This distributed quality responsibility ensures issues are addressed immediately by operators most familiar with that process step, rather than accumulating for discovery by final inspectors who must diagnose root causes after the fact.

How Does Standardization Reduce Variability in Finished Products?

Standardized work methods, equipment settings, and quality benchmarks minimize variation between operators and production runs. According to ASTM textile production standards, process control through standardization is the most effective method for achieving consistent results in garment manufacturing. When every operator follows the same procedures for tasks like stitch length, seam allowance, pressing temperatures, and finishing techniques, the resulting garments demonstrate remarkable consistency regardless of production volume or timing. This reliability builds client trust and reduces the sampling requirements for repeat orders since previous quality establishes predictable future outcomes.

How Does Workflow Transparency Benefit Client Relationships?

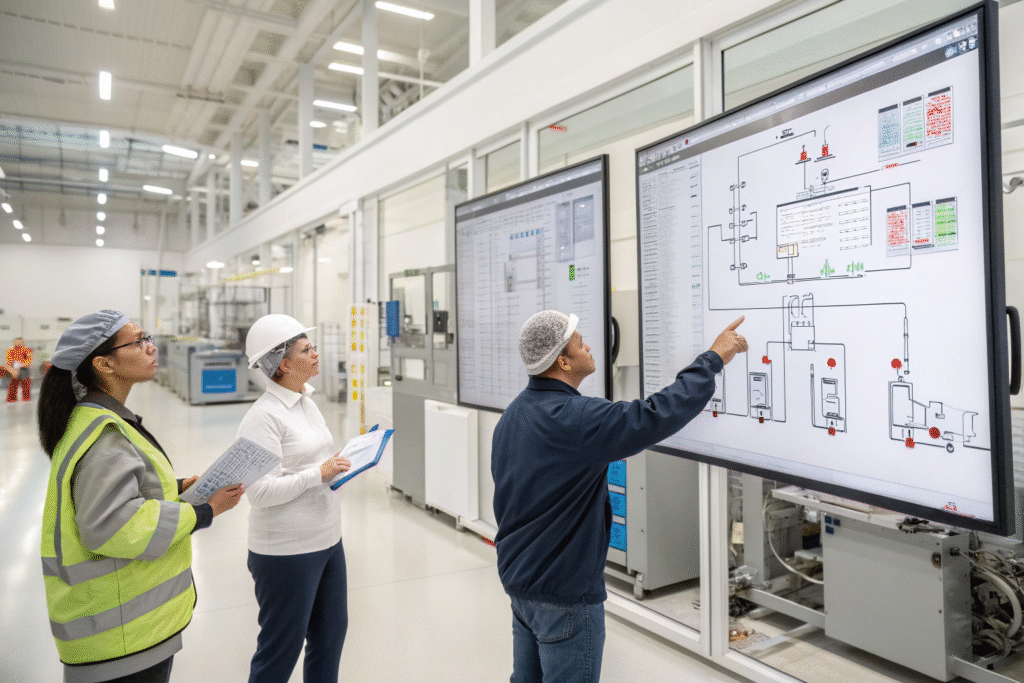

Clear workflows create natural transparency that keeps clients informed and confident in their manufacturing partner's capabilities and reliability.

When clients understand the production process, key milestones, and potential challenges, they can plan their operations accordingly and develop realistic expectations. This transparency transforms the client-manufacturer relationship from transactional to collaborative, with both parties working from the same information to achieve shared success.

How Does Production Visibility Build Client Trust?

When clients can track their order's progress through a transparent workflow system, anxiety about deadlines and quality diminishes. Modern manufacturers provide production tracking portals that show real-time status from fabric sourcing through shipping. This visibility demonstrates organizational competence and honesty—if delays occur, they're communicated early with clear explanations and solutions. According to Bain & Company research, companies with transparent operations achieve 30% higher client retention rates because trust reduces the temptation for clients to constantly seek alternative suppliers.

Why Does Process Understanding Improve Client Collaboration?

When clients understand factory workflows and constraints, they can make design and scheduling decisions that optimize manufacturability. Knowledgeable clients might adjust delivery timelines to avoid factory peak seasons, modify designs to simplify production, or approve alternative materials when shortages occur. This collaborative approach, documented in Harvard Business Review's manufacturing partnership studies, creates efficiencies benefiting both parties. The factory gains more predictable workflows, while the client receives better pricing, quality, and reliability—a virtuous cycle strengthening the partnership with each successful order.

How Does Workflow Optimization Support Scalability?

A clearly defined and continuously improved workflow creates a foundation that supports business growth without proportional increases in complexity or management overhead.

Scalable operations require systems rather than heroics—documented processes that new team members can learn quickly, quality standards that maintain consistency as volume increases, and management systems that provide visibility without constant direct supervision. Without this foundation, growth typically leads to declining quality, missed deadlines, and overwhelmed management.

What Workflow Elements Enable Efficient Scaling?

Modular workflow design allows factories to scale specific capacity constraints without overhauling entire systems. According to operations management principles, scalable workflows feature clear division of responsibilities, standardized training materials, and measurable performance indicators at each process step. This structure enables factories to add production lines, extend to multiple shifts, or even open additional facilities while maintaining consistent output quality. The workflow becomes a replicable template rather than a unique circumstance dependent on specific individuals or conditions.

How Does Continuous Improvement Sustain Long-Term Success?

A clear workflow establishes a baseline for measuring and implementing improvements over time. The Kaizen methodology of continuous improvement relies on standardized processes as the foundation for incremental enhancements. When workflows are documented and performance measured, factories can systematically identify opportunities for efficiency gains, quality improvements, or cost reductions. This data-driven approach to optimization creates compounding benefits—each small improvement builds upon previous enhancements, steadily increasing competitive advantage while maintaining operational stability during evolution.

Conclusion

A clear production workflow transforms garment manufacturing from unpredictable craft to reliable engineering, creating benefits that cascade throughout the organization and client relationships. From operational efficiency and quality consistency to client transparency and business scalability, workflow clarity provides the foundation for sustainable success in an increasingly competitive industry.

The most successful factories treat their workflows as living systems—clearly defined yet continuously refined based on performance data and changing market demands. If you're seeking a manufacturing partner with transparent, optimized workflows that ensure consistent quality and reliable delivery, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's discuss how our systematic approach to production can provide the stability and predictability your brand needs to grow confidently.