In the specialized world of children's fashion design, fabric selection transcends mere aesthetic choice to become a critical factor in safety, functionality, and commercial success. A well-curated fabric library serves as both creative catalyst and practical toolkit, enabling designers to make informed decisions that balance creativity with the unique demands of children's wear.

A fabric library is useful for kids clothing designers because it provides immediate tactile reference, ensures compliance with safety standards, facilitates faster prototyping, enables better cost forecasting, and inspires innovative design solutions through material experimentation. This resource transforms abstract design concepts into producible, safe, and commercially viable children's clothing.

The distance between a designer's sketch and a child happily wearing the finished garment is bridged by fabric choices that must satisfy technical, safety, and emotional requirements simultaneously. A comprehensive fabric library brings these considerations front and center during the design process rather than as afterthoughts during production. Let's explore how this essential tool supports excellence in children's wear design.

How does immediate tactile access accelerate design development?

The ability to physically handle and compare fabrics during the design process significantly reduces development time while improving decision quality. Digital representations cannot communicate crucial tactile information that determines how fabrics will perform in real-world use by active children.

Immediate tactile access accelerates design development by enabling instant comparison of drape and hand-feel, quick assessment of weight and thickness appropriateness, rapid color matching across fabric types, and hands-on evaluation of texture and comfort against children's sensitive skin. These physical interactions prevent costly mistakes that occur when designs progress based on digital images alone.

How does hands-on evaluation prevent design mistakes?

Physically handling fabrics reveals characteristics that photos cannot communicate—how a fabric drapes on a small body, whether it creates uncomfortable bulk under arms, how the texture feels against sensitive skin, or how colors interact under different lighting conditions. This tactile verification process catches potential issues before patterns are cut and samples made. For example, a beautiful printed twill might prove too stiff for a toddler's dress, or an appealing fleece might be uncomfortably heavy for active playwear—discoveries made instantly in a fabric library that would otherwise emerge only during sampling.

What rapid comparison capabilities enhance decision-making?

Side-by-side comparison of fabric options allows designers to evaluate relative weight, stretch recovery, opacity, and complementary textures more effectively than sequential viewing of digital swatches. This comparative analysis leads to more informed choices about which fabrics work together in coordinated collections and how different materials will perform for specific applications. Designers can immediately feel the difference between 180GSM and 220GSM interlock knit or assess whether two blues from different mills actually coordinate—decisions that would otherwise require multiple sample iterations to resolve.

How does fabric knowledge ensure safety compliance?

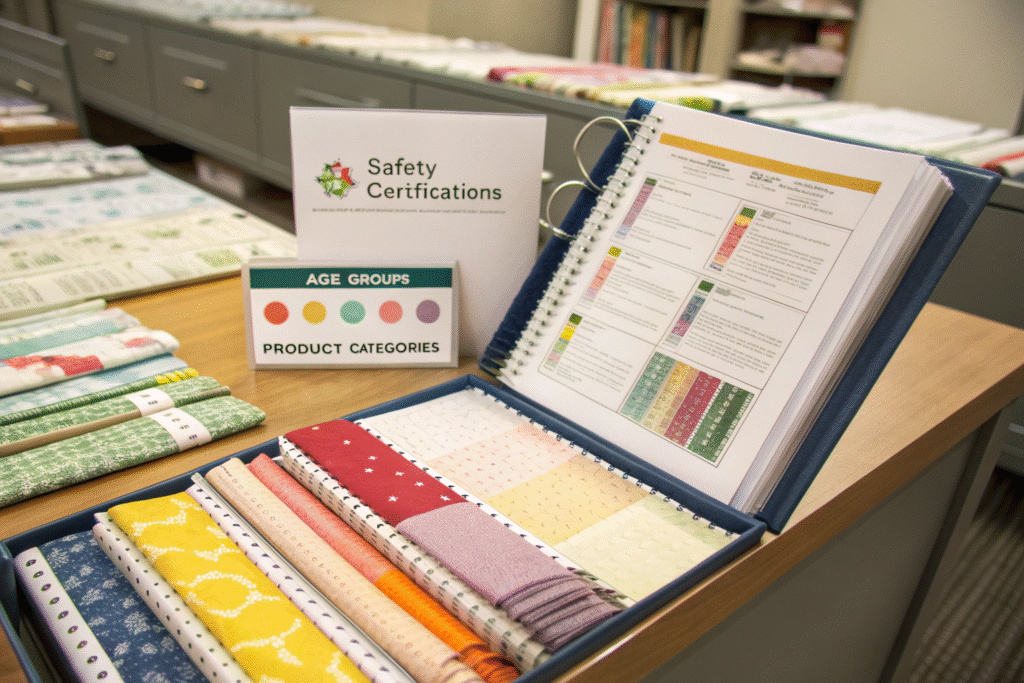

Children's fabrics must meet stringent safety standards that vary by market, age group, and product category. A well-documented fabric library serves as a compliance toolkit, providing immediate access to certified materials and their supporting documentation.

Fabric knowledge ensures safety compliance by providing immediate access to certified material documentation, enabling quick verification of testing status, facilitating selection of age-appropriate fabrics, and ensuring consistent use of pre-approved materials across collections. This systematic approach prevents compliance failures that could result in recalls or rejected shipments.

What safety certifications should be documented?

A comprehensive fabric library includes documentation for OEKO-TEX Standard 100 certification (limiting harmful substances), CPSIA compliance (US safety standards), flammability ratings (particularly important for sleepwear), and any organic certifications (GOTS, GRS). Having this information immediately available during fabric selection ensures designers choose materials that meet the required standards for their target market and product category. This prevents the common scenario where beautiful fabrics must be rejected late in development due to compliance issues.

How does material tracking prevent regulatory mistakes?

Maintaining a compliance tracker within the fabric library helps designers avoid using materials inappropriate for specific age groups or applications. For example, drawstrings are restricted in children's upper outerwear, requiring specific fabric and construction considerations. Fabrics for infants' wear have different safety requirements than those for older children. This organized approach prevents accidental specification of non-compliant materials that could create product liability issues or customs rejections.

How does fabric access inspire creative innovation?

Beyond practical considerations, a diverse fabric library serves as a creative catalyst, encouraging experimentation and innovation that distinguishes collections in a competitive market. The physical presence of materials stimulates design thinking in ways digital resources cannot match.

Fabric access inspires creative innovation by exposing designers to new material possibilities, encouraging unexpected combinations, facilitating texture exploration, and triggering ideas through serendipitous discovery. This hands-on creative process often leads to breakthrough designs that set trends rather than follow them.

How does material experimentation lead to unique designs?

The ability to freely combine, layer, and manipulate physical fabric swatches encourages creative exploration that digital tools cannot replicate. Designers might discover that quilting a technical fabric with an organic cotton creates an interesting texture, or that combining a stiff denim with a delicate lace produces unexpected contrast. These material experiments often evolve into signature design elements that define a collection's unique character. Many of our most successful design innovations began as spontaneous fabric combinations during library browsing sessions.

What role does seasonal updating play in maintaining creativity?

Regularly refreshing the fabric library with new seasonal offerings from mills ensures designers work with current options rather than revering to familiar standbys. This continuous renewal exposes the design team to emerging sustainable materials, innovative technical fabrics, and new finishing techniques that might otherwise be overlooked. We schedule quarterly library updates that include 10-15 new fabrics, ensuring our designers always have fresh inspiration while maintaining our core proven materials for continuity.

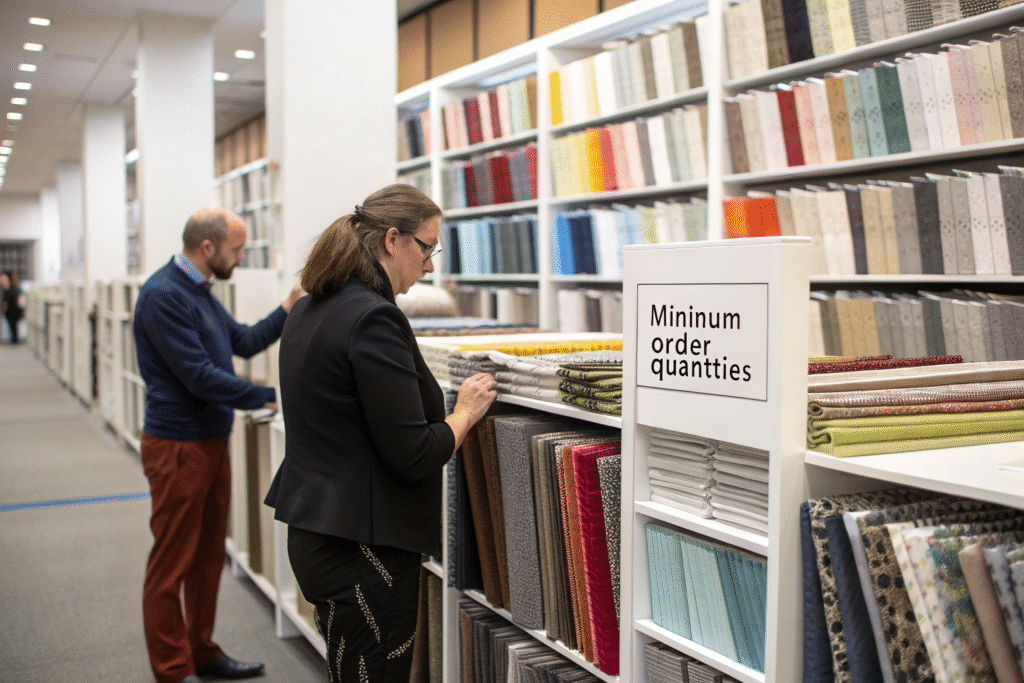

How does fabric organization improve cost management?

Strategic fabric selection significantly impacts production costs, and an organized library provides immediate visibility into price points, minimums, and availability that influence design decisions toward commercial viability.

Fabric organization improves cost management by providing immediate price comparison across similar options, identifying opportunities for fabric consolidation across styles, highlighting materials with favorable minimums, and enabling accurate cost forecasting during design development. This financial visibility prevents unpleasant surprises during costing stages.

How does fabric consolidation reduce costs?

When designers can easily identify fabrics already being used in other styles, they can make strategic decisions to consolidate material choices across the collection. This consolidation increases order volumes with specific mills, yielding better pricing through quantity discounts. It also reduces cut-and-sew complexity in the factory, as operators work with familiar materials rather than constantly adjusting to new fabrics. Our tracking shows that strategic fabric consolidation typically reduces material costs by 8-12% while simplifying production logistics.

What costing advantages come from detailed fabric documentation?

A well-maintained fabric library includes current pricing, minimum order quantities, lead times, and availability information for each material. This allows designers to calculate accurate cost estimates during the design phase rather than discovering cost issues after samples are made. When a designer can immediately see that a beautiful Italian cotton costs $18/yard with a 2,000-yard minimum versus a comparable Korean alternative at $12/yard with 500-yard minimum, they can make informed trade-offs between aesthetic aspirations and commercial reality.

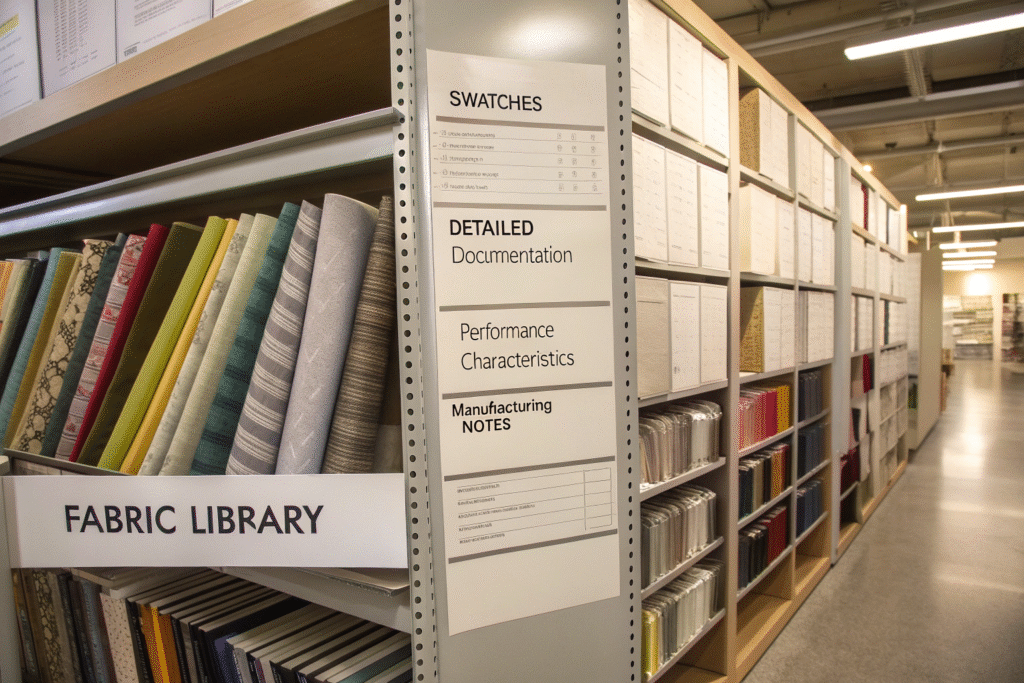

How does technical specification support enhance production planning?

Beyond creative applications, a comprehensive fabric library serves as a technical resource that bridges the gap between design vision and manufacturing execution. Detailed specifications prevent miscommunication and production errors.

Technical specification support enhances production planning by providing precise composition details, care instruction requirements, performance characteristics, and manufacturing notes that ensure consistent interpretation from design room to factory floor. This technical foundation prevents costly production errors and quality inconsistencies.

What technical details should be documented for each fabric?

Beyond basic composition, a thorough fabric library includes technical specifications like weight (GSM or ounces), width, stretch percentage and recovery, shrinkage expectations, colorfastness ratings, pilling resistance, and recommended needle sizes. This information helps pattern makers create appropriate patterns, helps production teams set correct machine settings, and helps quality control establish appropriate inspection standards. This comprehensive documentation transforms subjective fabric descriptions into precise manufacturing instructions.

How does care instruction documentation prevent customer issues?

Detailed care requirement information for each fabric ensures accurate labeling and prevents customer dissatisfaction from improper care. Some technical fabrics require specific washing instructions, while delicate embellishments might need special handling. Having this information readily available during design prevents the common problem of generic care labels that lead to damaged garments and unhappy customers. We include recommended care instructions in each fabric's documentation, which flows directly into our final label requirements.

Conclusion

A comprehensive fabric library represents far more than a collection of swatches—it's an essential strategic tool that supports creative innovation, ensures safety compliance, enables cost control, and facilitates smooth production transition. For children's clothing designers specifically, where fabric choices directly impact safety, comfort, and durability, this resource becomes indispensable for creating successful products that satisfy both children and their parents.

The investment in developing and maintaining a well-organized fabric library pays continuous dividends through reduced development time, fewer production errors, better cost management, and more innovative designs. In the competitive children's wear market, this material intelligence provides a significant advantage that separates trend-following brands from trend-setting ones.

Ready to build or enhance your fabric library for children's wear design? Our manufacturing expertise includes extensive fabric knowledge and sourcing relationships that can strengthen your design development process. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can support your fabric selection and development needs.