Creating a comprehensive tech pack is the most critical step in transforming your clothing designs into manufacturable products. As manufacturers who receive hundreds of tech packs monthly, we've identified exactly what separates successful, clear tech packs from those that cause production delays and quality issues.

The key elements of a kids clothing tech pack include detailed technical drawings, complete measurement specifications, comprehensive materials information, precise construction details, and clear labeling requirements. A well-prepared tech pack serves as the universal language between designers and manufacturers, ensuring everyone works from the same precise information to achieve consistent, high-quality results. Missing or unclear information in any of these areas can lead to costly mistakes and production delays.

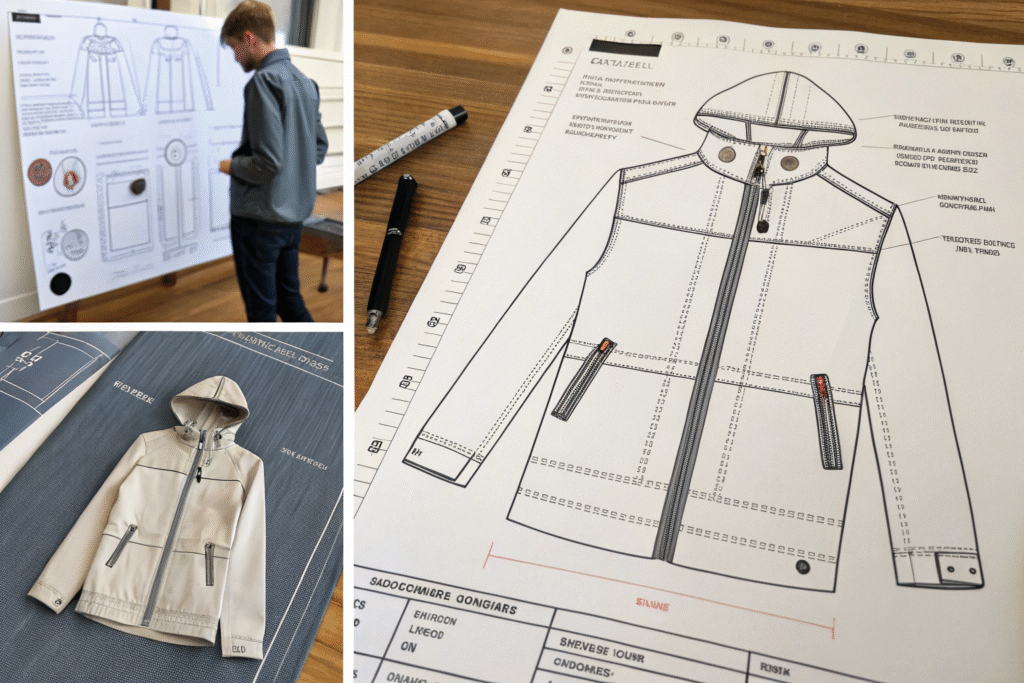

Why Are Technical Drawings The Foundation of Your Tech Pack?

Technical drawings provide the visual blueprint that manufacturers use to understand your design intent and construction requirements. These drawings differ significantly from fashion illustrations by focusing on precise details rather than artistic expression.

Complete technical drawings include both flat sketches and construction details that show the garment from all angles. Front, back, and side views are essential, along with close-up drawings of any unique design elements, seam treatments, or special features. These drawings must be to scale and include all components, from main fabrics to trims and fasteners, providing a comprehensive visual guide for pattern makers and production teams.

What Views Should Your Technical Drawings Include?

Comprehensive technical drawings should show the garment from multiple angles to eliminate ambiguity. Essential views include front, back, and side profiles, plus any special details that require clarification. For complex garments, include separate drawings showing interior construction, such as lining details or pocket placements. These technical flats serve as the primary reference for pattern creation and ensure all team members visualize the same final product. Clear, standardized drawings prevent misinterpretation and ensure consistency across production runs.

How Do Construction Details Improve Manufacturing Accuracy?

Construction detail drawings zoom in on specific areas that require special attention or unique techniques. These might include seam types, hem treatments, placket constructions, or special finishing methods. By specifying exact construction methods for each component, you ensure the factory replicates your quality standards and design integrity. Detailed construction drawings are particularly important for children's wear, where safety considerations like reinforced seams and secure fastenings are paramount.

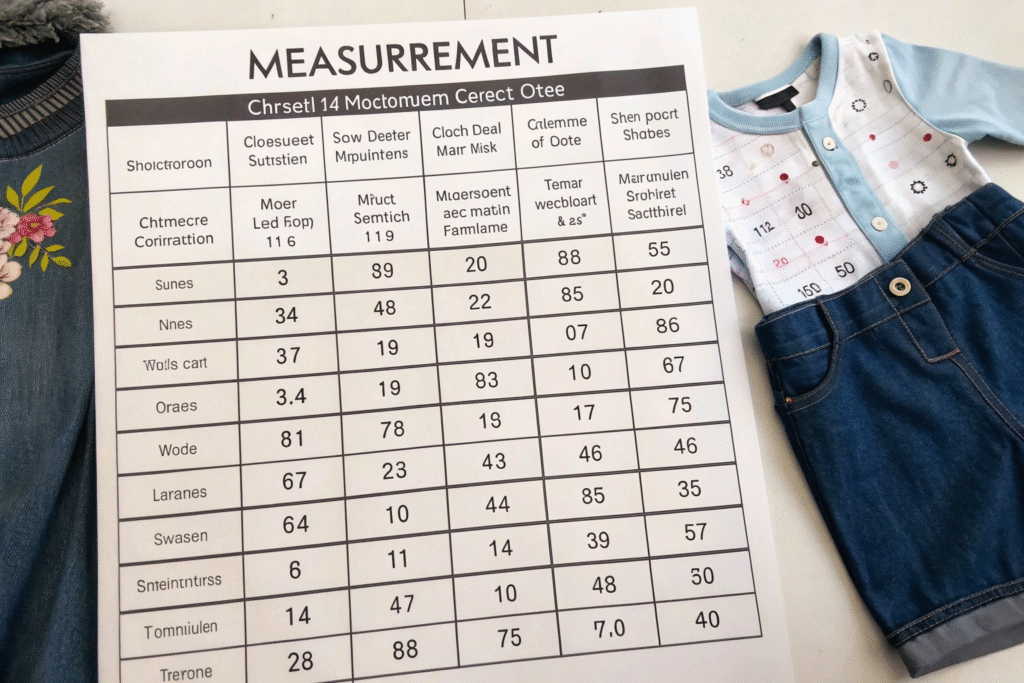

What Measurement Specifications Ensure Perfect Fit?

Precise measurement specifications form the critical bridge between your design vision and the actual manufactured product. In kids wear, where proper fit affects both comfort and safety, accurate measurements are non-negotiable.

A complete measurement chart includes point-of-measurement definitions for each size in your range, grade rules between sizes, and acceptable tolerance levels. For children's clothing, special attention must be paid to ease allowances for movement and growth, as well as proportion considerations for different age groups. Clear measurement specifications prevent fit issues and ensure consistency across your entire collection.

How Do You Create Comprehensive Size Specifications?

Complete size specifications include every critical measurement point for each size in your range. For a simple t-shirt, this might include 15-20 different measurements from shoulder width to hem length. Using standardized point of measurement terminology ensures everyone interprets each measurement consistently. Include both body measurements and garment measurements, clearly indicating the relationship between them through ease specifications. This comprehensive approach eliminates guesswork during pattern making and sample development.

Why Are Grade Rules Essential for Kids Wear?

Grade rules define how measurements change between sizes, ensuring proportional scaling rather than simple enlargement. Children's bodies don't grow uniformly—torso length, arm length, and chest circumference develop at different rates. Proper grading rules account for these proportional differences, creating clothing that fits properly at each size rather than simply being larger or smaller. Well-defined grade rules are especially crucial for kids wear, where improper proportions can compromise both comfort and functionality.

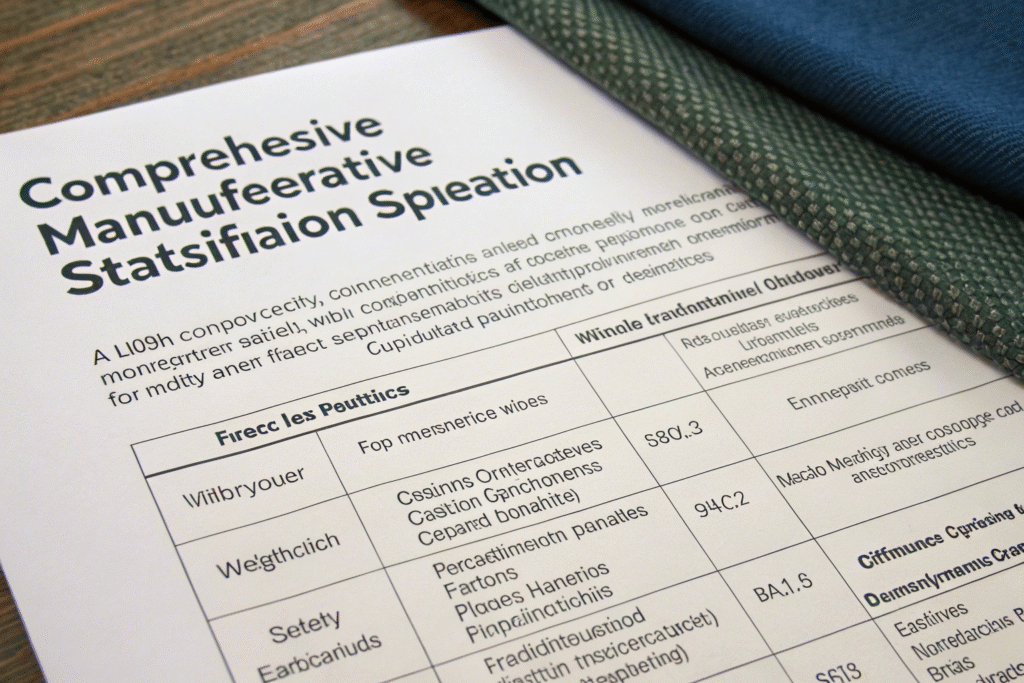

What Materials Information Prevents Production Errors?

Comprehensive materials specification ensures your manufacturer sources exactly the right components to achieve your desired quality, safety, and aesthetic standards. This section leaves no room for assumption or substitution.

Detailed materials information includes not only fabric composition and weight but also performance requirements, safety certifications, and specific source information when necessary. For children's wear, additional considerations include flammability standards, chemical restrictions, and physical safety requirements for all components from main fabrics to the smallest trim.

What Fabric Details Are Most Critical?

Complete fabric specifications include composition percentages, weight (GSM or ounces), width, stretch percentage, and care requirements. Also include performance expectations like colorfastness, pilling resistance, and shrinkage limits. For children's wear, specifically note compliance with relevant safety standards regarding flammability and chemical content. Providing fabric source information or approved substitutes helps manufacturers maintain consistency when original materials become unavailable.

How Do You Specify Trims and Components?

Trim specifications must be equally detailed, including item descriptions, materials, sizes, colors, and application methods. For children's wear, pay special attention to safety considerations—specify breakaway features for drawstrings, secure attachment methods for appliqués, and non-toxic materials for all components. Clear trim specifications prevent substitutions that might compromise safety or quality while ensuring visual consistency across production runs. Include physical samples or approved substitutes for critical trims whenever possible.

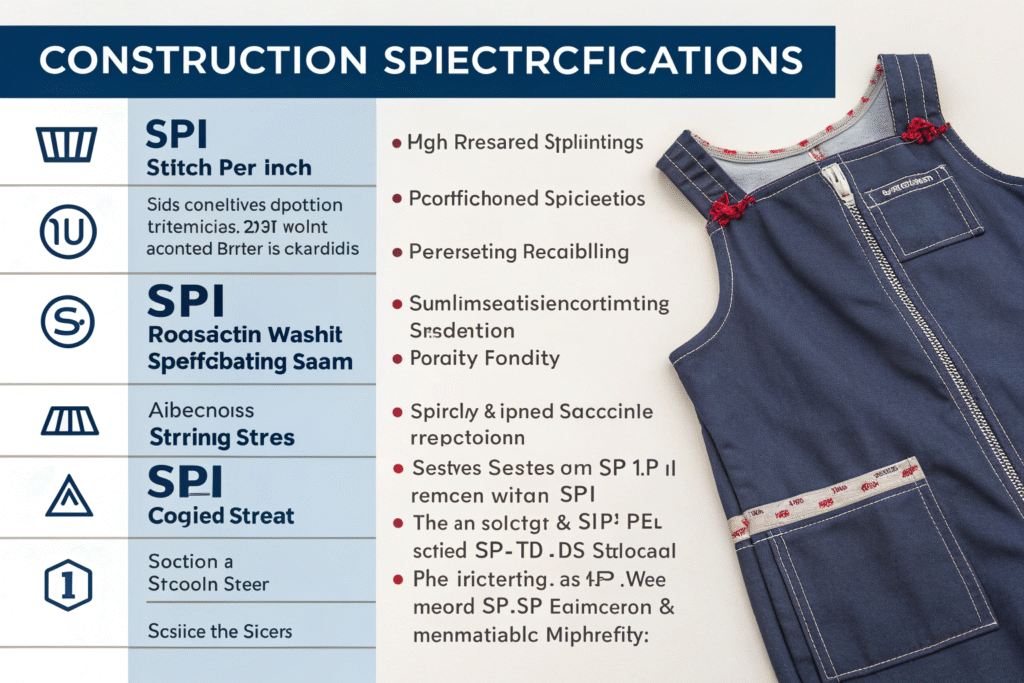

What Construction Details Ensure Quality Execution?

Construction specifications translate your quality standards into actionable manufacturing instructions. This section details exactly how each component should be assembled to achieve your desired finish and durability.

Comprehensive construction details include stitch types and SPI (stitches per inch) for each seam, seam allowance specifications, finishing methods, and pressing requirements. For children's wear, emphasize reinforced stitching in high-stress areas, safe finishing methods that prevent skin irritation, and durability considerations that withstand active use and frequent washing.

How Do Stitch Specifications Impact Quality?

Stitch type and density specifications directly affect both appearance and durability. Different seam types require different stitch formations—lockstitch for straight seams, overlock for edge finishing, and chainstitch for hemming. Specify stitch types and SPI for each application, with higher stitch counts typically indicating better quality. For children's wear, reinforce high-stress areas like crotches and armholes with additional rows of stitching to prevent seam failure during active use.

What Finishing Details Separate Good from Great?

Finishing details transform a basic garment into a quality product. Specify edge finishing methods, interfacing applications, pressing standards, and final inspection criteria. For children's wear, emphasize quality finishing that eliminates rough edges, secures all components, and maintains softness against sensitive skin. Detailed finishing specifications ensure consistency and quality across all production, preventing variations that can damage brand reputation and customer satisfaction.

Conclusion

A comprehensive kids clothing tech pack serves as your single source of truth throughout the manufacturing process, bridging the gap between creative vision and production reality. By including detailed technical drawings, precise measurements, complete materials specifications, and thorough construction details, you provide manufacturers with everything needed to execute your designs accurately and consistently.

The time invested in creating thorough tech packs pays dividends through smoother production, higher quality outcomes, and stronger manufacturer relationships. If you need assistance developing comprehensive tech packs or want to work with a manufacturer who values detailed specifications, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's discuss how we can help you transform your designs into perfectly executed products.