Running a seasonal kids clothing business comes with unique inventory challenges. As a manufacturer who has partnered with hundreds of seasonal brands, I've seen what separates successful companies from those that struggle with overstock or shortages.

Effective inventory management for seasonal kids clothing requires accurate demand forecasting, flexible manufacturing partnerships, strategic discounting plans, and data-driven purchasing decisions. The key is balancing having enough stock to meet peak demand while minimizing leftover inventory that becomes difficult to sell. Here's how successful brands manage this delicate balance.

What Forecasting Methods Prevent Overstock and Shortages?

Accurate forecasting is your first line of defense against inventory problems. The goal is to predict demand as precisely as possible before the season begins. We help our partners develop forecasting models that combine multiple data sources.

Start by analyzing historical sales data from previous seasons. Look for patterns in which items sold quickly and which lingered. Combine this with market trend research for upcoming seasons. We also recommend testing new designs with small pre-order batches before committing to full production. This approach minimizes risk while providing valuable early demand indicators.

How Can Historical Data Improve Your Forecasts?

Historical sales data provides your most reliable forecasting foundation. Analyze which styles, colors, and sizes performed best during similar past seasons. Pay special attention to sell-through rates—the percentage of inventory that actually sold. This reveals what your customers truly want. Look beyond total numbers to understand which items had the highest sell-through rate, as this indicates strong customer demand and helps prevent both overordering and underordering.

Why Should You Test Designs Before Full Production?

Testing designs with limited initial runs protects against costly mistakes. Launch small batches of new styles early in your planning cycle. Monitor how quickly they move compared to established favorites. This market testing provides concrete data to refine your full-season order quantities. Many of our most successful partners use this strategy to identify breakout hits before committing to large-scale production planning, ensuring they allocate manufacturing capacity to the items with proven demand.

How Can Flexible Manufacturing Help Inventory Management?

Your manufacturing partnership directly impacts inventory flexibility. Traditional factories require huge minimums and long lead times, but modern approaches offer more adaptability for seasonal businesses.

We've developed a phased production model specifically for seasonal brands. Instead of manufacturing the entire season's inventory at once, we produce in strategic batches. The core collection ships first, followed by replenishment orders of best-sellers as demand patterns emerge. This approach requires close collaboration but significantly reduces the risk of being stuck with unpopular styles while missing sales on trending items.

What Are the Benefits of Phased Production?

Phased production transforms your inventory risk management. By manufacturing in controlled batches throughout the season, you maintain flexibility to respond to actual sales data. If a particular style sells faster than anticipated, you can quickly manufacture additional units. If another underperforms, you can reduce or cancel later batches. This approach requires working with manufacturers who offer quick turnaround capabilities, but it dramatically improves inventory efficiency and reduces markdowns.

How Do Smaller Minimums Reduce Inventory Risk?

Lower minimum order quantities (MOQs) allow for greater assortment diversity with less risk. Instead of ordering 500 units of one style, you might order 100 units each of five different styles. This lets you test more designs and cater to varied customer preferences without committing heavily to untested products. Our factory specializes in accommodating lower MOQs for established brands, recognizing that better inventory control often outweighs the per-unit cost advantages of massive single runs.

What Inventory Strategies Maximize Profit Margins?

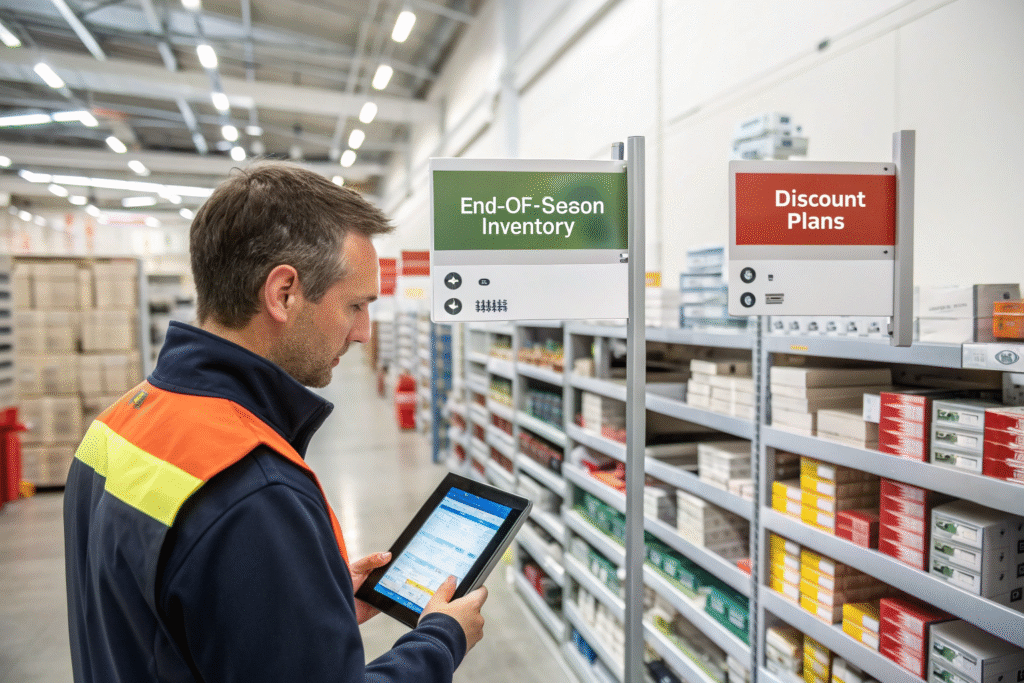

Smart inventory management directly impacts your profitability. The right strategies help you sell more at full price while efficiently clearing remaining stock.

Implement a tiered pricing strategy from the beginning. Plan your discount timing and percentages in advance rather than making reactive decisions. Also, develop a clear channel strategy for end-of-season inventory. Some items may sell better through outlet channels, while others perform well in targeted email campaigns to loyal customers.

When Should You Implement Strategic Markdowns?

Timed markdowns should be part of your initial inventory plan rather than a panic response. Begin with modest discounts (15-20%) about two-thirds through the season to maintain momentum. Reserve deeper discounts for truly slow-moving items as the season closes. This structured approach typically yields higher overall gross margin return on investment than either no planned discounts or emergency clearance pricing. The key is systematic rather than reactive price reductions.

How Can Multiple Sales Channels Help?

Diversifying your sales channels provides important inventory flexibility. Your main e-commerce site might sell most inventory at full price, while flash sale sites can help move excess stock efficiently. Seasonal pop-up shops, wholesale partnerships, and targeted social media campaigns each serve different purposes in your inventory management strategy. A multi-channel approach ensures you have options beyond drastic discounting on your primary e-commerce platform when seasons change.

What Technology Solutions Streamline Inventory Management?

Modern inventory management requires the right technological tools. The days of spreadsheets and guesswork are over for competitive seasonal businesses.

Invest in an inventory management system that integrates with your point-of-sale, e-commerce platform, and manufacturing partners. Cloud-based systems provide real-time visibility into stock levels across all locations and channels. This integration enables automated reordering, detailed reporting, and data-driven decision making throughout the season.

Which Software Features Are Most Important?

The most valuable inventory systems offer real-time synchronization, demand forecasting tools, and multi-location tracking. Real-time updates prevent overselling and provide accurate available-to-promise information to customers. Forecasting tools analyze sales velocity to predict when you'll need replenishment. Multi-location management is essential if you sell through both online and physical channels. These features collectively create an inventory management system that reduces manual work while improving accuracy.

How Does Data Integration Help Decision Making?

Integrated data transforms inventory management from reactive to proactive. When your inventory system connects with manufacturing partners like us, we can see real-time sales data and help plan replenishment production before you run critically low. This seamless data flow enables faster response to trends and prevents stockouts of best-selling items. The goal is creating a connected supply chain visibility system where information flows smoothly from customer sales back to manufacturing planning.

Conclusion

Successful inventory management for seasonal kids clothing requires combining accurate forecasting, flexible manufacturing partnerships, strategic pricing, and modern technology. By implementing these practices, you can maximize sales during peak seasons while minimizing costly leftover inventory.

The right manufacturing partner is crucial for implementing these inventory strategies effectively. If you're looking for a factory that understands seasonal business needs and offers flexible production solutions, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's discuss how we can help you optimize your inventory management for better profitability and fewer seasonal headaches.