As a parent or a children's wear brand buyer, you want the best for infants. You look for soft fabrics and safe materials. The use of natural dyes like those from walnut shells is a growing trend in the baby clothing industry. But are these dyes truly safe for the most delicate skin? This question is vital for anyone involved in bringing infant wear to market.

Using natural dyes like walnut shells in infant clothing is generally considered safe when processed correctly and tested rigorously, but it requires careful attention to sourcing, manufacturing standards, and certifications to ensure no harmful residues are present. The appeal of natural dyes aligns with the demand for non-toxic, eco-friendly baby products. However, "natural" does not automatically mean "safe for infants." This article will explore the safety profile, manufacturing processes, and key considerations for brands looking to source infant wear dyed with walnut shells.

Understanding the nuances of material safety is crucial for making informed sourcing decisions. Let's delve into the specifics to ensure the products you offer provide both style and safety.

What are the benefits of using walnut shell dyes?

The move towards natural dyes is not just a fad. It is a response to a market that values sustainability and safety. Walnut shell dyes offer specific advantages that are worth noting for any children's wear brand. They can be a unique selling point for your collection.

Walnut shell dyes provide a natural, eco-friendly coloring option that produces rich, earthy brown tones without the use of synthetic chemicals often found in conventional dyes. The primary benefits include their biodegradability and the reduction of environmental pollution compared to some synthetic alternatives. For brands targeting eco-conscious parents, this is a significant advantage.

How do walnut shell dyes enhance brand value?

Using natural dyes can significantly boost your brand's image. Today's consumers, especially in North America and Europe, are increasingly aware of environmental and health issues. By incorporating sustainable practices like using walnut shell dyes, you align your brand with these values. This commitment can be a powerful marketing tool. It shows that your company cares not just about profits, but about the planet and the well-being of children. This builds trust and loyalty, which are essential for long-term success in the competitive children's wear market. Furthermore, partnering with a manufacturer like us, who understands and implements these eco-friendly dyeing processes, ensures your brand story is both authentic and compelling.

What makes walnut shell dyes an eco-friendly choice?

The eco-friendly nature of walnut shell dyes stems from their source and impact. They are derived from a renewable resource—walnut hulls, which are often a byproduct of the food industry. This reduces waste. The dyeing process itself typically requires less water and energy than some synthetic dye processes. More importantly, these dyes are biodegradable, meaning they break down naturally without releasing harmful toxins into the environment. This is a key point for brands that must comply with strict international environmental standards and for buyers who are sensitive to the ecological footprint of their products. It's a step towards a cleaner supply chain.

What safety certifications should I look for?

When sourcing infant wear, safety is the top priority. Certifications are your proof of compliance and safety. They are not just pieces of paper; they are assurances that the product has been tested and meets rigorous standards. For any brand owner like Ron, this due diligence is non-negotiable.

You must look for certifications that specifically verify the safety of dyes and fabrics used in infant clothing. These certifications are independent validations that the materials are free from harmful substances. They protect your brand from the risks of selling unsafe products and give your customers peace of mind.

Why is Oeko-Tex Standard 100 crucial?

The OEKO-TEX Standard 100 certification is one of the most important worldwide for textiles. It tests for a list of harmful substances, including heavy metals, pesticides, and allergenic dyes. If a garment carries this label, it means every component, including the thread and buttons, has been tested and is harmless to human health. For infant wear dyed with walnut shells, this certification is crucial. It provides scientific confirmation that the natural dyes do not contain unsafe levels of contaminants. This directly addresses a common pain point for buyers like Ron, who worry about suppliers falsifying certificates. We provide genuine certifications for all our products, ensuring complete transparency.

What does GOTS certification cover?

The Global Organic Textile Standard (GOTS) is another key certification. It covers both the organic status of the fibers (like cotton) and the environmental and social criteria of the entire manufacturing process. This includes strict limits on the chemicals and dyes that can be used. For walnut shell dyes to be used in GOTS-certified clothing, the entire production chain must be certified. This holistic approach guarantees that the product is not only made with organic materials but also in an environmentally and socially responsible manner. It is a comprehensive guarantee that aligns with the high standards of the mid-to-high segment brands we serve.

How does the dyeing process affect safety?

The safety of a natural dye is not just about the source material. The manufacturing process plays an equally important role. How the walnut shells are processed into a dye and applied to the fabric can determine the final product's safety for an infant's sensitive skin.

A controlled and transparent dyeing process is essential to ensure that the final garment is free from irritants or harmful residues. This involves everything from sourcing the raw materials to the final fixation of the color on the fabric.

Can the dyeing process introduce allergens?

While walnut shell dyes are natural, it is important to consider potential allergens. The primary concern would be for infants with a specific tree nut allergy. However, during the proper dyeing process, the proteins that cause allergic reactions are typically broken down or removed. The dyes are extracted from the hulls, not the nut meat, and go through extensive processing and washing. Reputable manufacturers will conduct thorough testing to ensure the final dyed fabric does not contain detectable levels of allergenic proteins. This is a key part of our quality control at Fumao Clothing, where we prioritize infant safety above all else.

What quality control steps are necessary?

| Robust quality control is the backbone of safe garment production. For walnut shell dyes, this involves multiple steps. First, the raw walnut hulls must be sourced from reliable suppliers. Then, the dye extraction and application processes must be monitored to prevent contamination. Finally, the dyed fabric must undergo a series of tests, including: | Test Type | Purpose |

|---|---|---|

| Ph Value Test | Ensures the fabric skin-friendliness. | |

| Colorfastness Test | Checks if the dye rubs off or bleeds. | |

| Allergen Screening | Verifies the absence of common allergens. |

These steps, combined with the certifications mentioned earlier, create a multi-layered safety net. This rigorous process ensures that the beautiful, natural color of walnut dyes does not come at the cost of an infant's comfort or health.

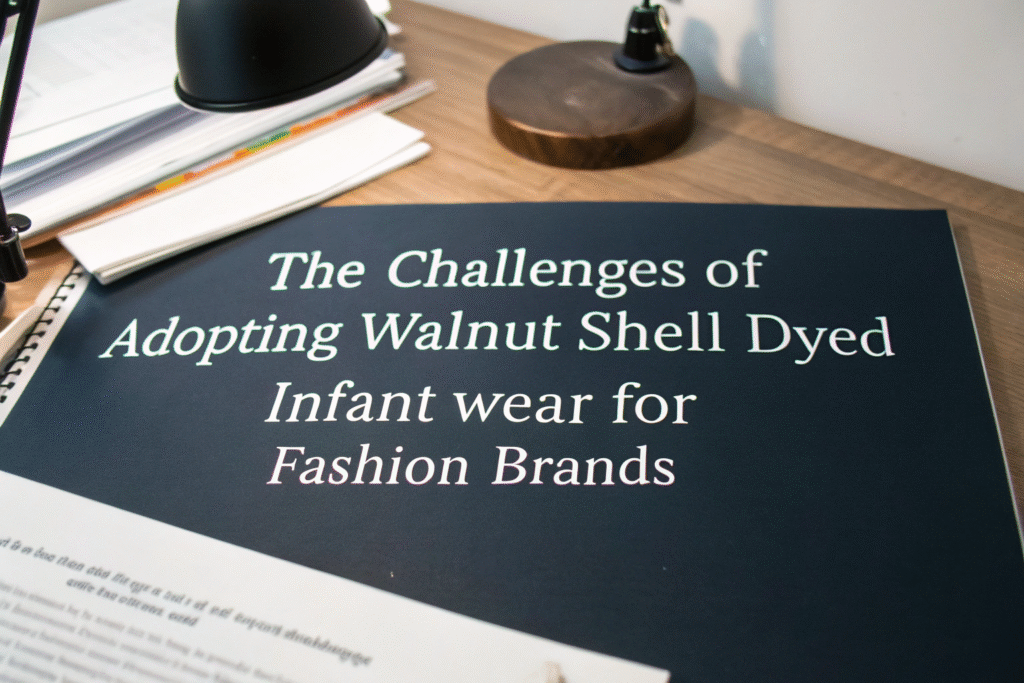

What are the main challenges for brands?

Adopting any new material or process comes with its own set of challenges. For brands considering walnut shell dyed infant wear, being aware of these hurdles beforehand allows for better planning and risk management. This knowledge is power in the fast-paced fashion industry.

The main challenges often revolve around supply chain consistency, color limitations, and cost considerations. Understanding these factors helps brands like yours make strategic decisions.

Is the color range limited with natural dyes?

Yes, one of the primary challenges is the limited color palette. Unlike synthetic dyes that can produce virtually any color, natural dyes like walnut shells typically yield a range of earthy tones—browns, tans, and beiges. While this is perfect for certain aesthetics and collections, it may not suit every brand's vision. However, this limitation can also be turned into a strength. It allows brands to build a cohesive, natural-themed collection that tells a clear story. It appeals to a specific segment of the market that appreciates muted, organic colors for their babies.

How can I ensure a stable supply chain?

A stable supply chain for natural dyes requires a reliable manufacturing partner. Challenges can include seasonal variations in the walnut supply and the need for specialized knowledge in natural dyeing techniques. This is where a partner like Fumao Clothing becomes invaluable. With decades of experience and five dedicated production lines, we have established a robust supply chain that can manage these variables. We offer DDP (Delivered Duty Paid) services, handling all logistics to ensure on-time delivery and prevent the missed selling seasons that are a major pain point for buyers like Ron. Our expertise turns this potential challenge into a seamless experience for our clients.

Conclusion

In summary, walnut shell dyes can be a safe and attractive option for infant wear when partnered with a manufacturer who prioritizes rigorous testing, holds relevant safety certifications, and maintains transparent processes. The benefits of eco-friendliness and brand enhancement are clear, but they must be balanced with an understanding of the challenges like color limits and supply chain management.

Ultimately, the safety of any garment lies in the hands of the manufacturer. Choosing a partner with a proven track record in quality and reliability is the most critical step. If you are looking to develop a high-quality, safe, and stylish infant wear collection using natural dyes or other materials, we have the expertise and infrastructure to bring your vision to life.

For a reliable partnership that values quality and on-time delivery as much as you do, contact our Business Director Elaine to discuss your next clothing order. Reach her at elaine@fumaoclothing.com. Let's create something beautiful and safe together.