As a children's clothing manufacturer, I know that keeping up with safety regulations is not just about compliance—it's about protecting our littlest customers. If you're sourcing infant sleepwear for the US market, you've likely heard whispers about recent CPSIA changes. Falling behind on these updates can lead to costly recalls, seized shipments, and damaged brand reputation. This article will cut through the confusion and give you a clear, actionable guide to the latest CPSIA requirements for infant sleepwear, ensuring your products are safe, compliant, and market-ready.

The new CPSIA updates for infant sleepwear primarily involve stricter tracking and verification of compliance, with a heightened focus on the Consumer Product Safety Commission's (CPSC) enforcement of flammability standards and the use of specific tracking labels. Understanding these changes is critical for any brand importing into the United States to avoid significant penalties. For over a decade, our factory has navigated the evolving landscape of US safety standards, turning regulatory compliance from a headache into a seamless part of our production process. Let's dive into the specifics so you can source with confidence.

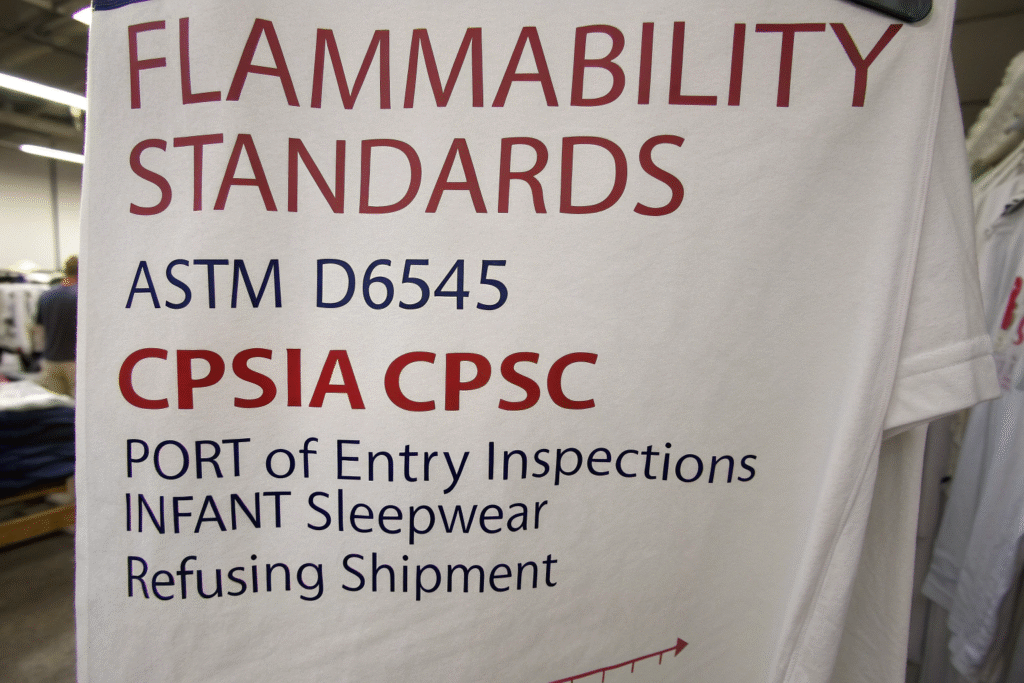

Key Changes in Flammability Standards (ASTM D6545)

The flammability of children's sleepwear is non-negotiable. The recent CPSIA emphasis has reinforced the existing standard, ASTM D6545, which outlines the mandatory testing procedures for flame resistance. Many buyers mistakenly think this is a new rule, but the update is really about more rigorous enforcement and documentation. The CPSC is now conducting more frequent port-of-entry inspections, and any shipment of infant sleepwear failing to meet these standards will be refused entry.

What is the ASTM D6545 standard for flame resistance?

The ASTM D6545 standard is the recognized test method for establishing the flame resistance of children's sleepwear. It simulates various conditions to ensure the fabric will not ignite easily or burn rapidly. This standard is a direct extension of the CFR 1615 and CFR 1616 regulations set by the CPSC. For manufacturers, this means every batch of fabric used in sleepwear must pass this test. We integrate this testing protocol early in our production cycle, working with CPSC-accredited third-party labs to certify our fabrics before cutting and sewing even begins. This proactive approach prevents costly last-minute failures and ensures consistent quality control from the raw material stage.

How can manufacturers ensure consistent compliance?

Ensuring consistent compliance requires a multi-layered approach. First, it's essential to partner with a manufacturer that has a robust internal quality management system. This system should include strict protocols for fabric sourcing, with a focus on inherently flame-resistant materials. Second, maintaining meticulous records of all third-party lab test reports for each production run is no longer optional; it's your primary defense during a CPSC audit. We provide our clients with a complete compliance dossier for every order, which includes detailed test reports from internationally recognized labs like QIMA or Bureau Veritas. This documentation is crucial for proving due diligence and facilitates a smoother customs clearance process under the new CPSIA enforcement regime.

Updated Requirements for Tracking Labels & Documentation

The CPSIA's tracking label requirements have been a point of focus in recent updates. The law mandates that all children's products, including infant sleepwear, must have a permanent, distinguishing mark on the product and its packaging. This label must contain information that allows the manufacturer, the location, and the date of production to be traced. The "new" aspect is the CPSC's stricter interpretation of "permanent and discernible," meaning the label must remain legible for the entire useful life of the product.

![]()

What information must be on a CPSIA-compliant tracking label?

A fully compliant tracking label must contain three key pieces of information: the source of the product (manufacturer or private labeler), the date of production (at least month and year), and batch information (like a batch or lot number). This information allows for efficient recalls if necessary. For brands, this means your manufacturer must be willing and able to incorporate this specific data into the garment's label, typically sewn into the neckline or side seam. We work closely with our clients to design labels that meet these legal requirements without compromising the garment's aesthetics, ensuring the information is clear but discreet.

Why is detailed documentation critical for importers?

Detailed documentation is your safety net. In the event of a CPSC inquiry or a customs hold, your paperwork is the first thing officials will examine. This includes the Children's Product Certificate (CPC), which is a mandatory document that attests to a product's compliance with all applicable children's product safety rules. The CPC must be based on testing from a CPSC-accepted laboratory. Without a properly executed CPC, your shipment risks being detained at the border. We simplify this for our partners by preparing the CPC and all supporting test reports as a standard part of our service, ensuring that the complex documentation process of the Consumer Product Safety Improvement Act is handled expertly, reducing the risk of delays for our clients.

Implications for Sourcing from Overseas Suppliers

Sourcing infant sleepwear from international manufacturers like those in China adds another layer of complexity to CPSIA compliance. The responsibility for compliance ultimately falls on the US importer (the brand or distributor), not the foreign factory. This makes choosing the right manufacturing partner absolutely critical. The recent CPSIA updates mean that importers must exercise heightened due diligence in verifying their supplier's compliance capabilities.

What are the key questions to ask your supplier about CPSIA?

Before placing an order, you must ask your supplier specific questions. Can you provide a valid CPC for this product? Which CPSC-accredited third-party lab do you use for flammability testing? Can you show me a sample of the tracking label? A reputable manufacturer will have clear, confident answers and be able to provide evidence immediately. We encourage potential clients to audit our processes and documentation. Our transparency in providing lab reports and explaining our compliance protocols has been a key factor in building long-term trust with major US brands.

How does DDP shipping mode mitigate compliance risks?

Choosing a Delivered Duty Paid (DDP) shipping arrangement can significantly reduce your compliance risks. When you work with a manufacturer like us who offers DDP, we take on the responsibility for the entire shipping process, including customs clearance. This means we are incentivized to ensure all CPSIA documentation is flawless because any issues at US customs become our problem to solve. This model aligns our interests perfectly with yours; we succeed only when your goods arrive on time and without regulatory hiccups. It effectively turns your supplier into a compliance partner, sharing the burden of navigating the intricacies of US import regulations for children's products.

The Role of Third-Party Testing and Certification

Third-party testing is the cornerstone of CPSIA compliance. The updates have not changed the fundamental requirement that testing must be conducted by a laboratory accepted by the CPSC. However, there is a greater emphasis on the integrity of the testing process itself. The CPSC has increased its scrutiny of labs and manufacturers to prevent the falsification of certificates, a known pain point for many buyers.

How to verify a third-party lab's CPSC accreditation?

Verifying a lab's accreditation is straightforward. The CPSC maintains a public searchable database on its website of all accepted testing laboratories. You should always ask your supplier for the name of the lab they use and cross-reference it with this official list. Never accept a test report from a lab that is not on the list. We exclusively use labs that are CPSC-accredited for children's product testing, and we provide the lab's accreditation number directly on the CPC for easy verification. This level of transparency is essential for building a reliable supply chain.

What does a valid Children's Product Certificate (CPC) include?

A valid Children's Product Certificate is a document that must include specific information by law. It must list the product it covers, reference every applicable children's product safety rule (like flammability standards 16 CFR Part 1615 and 1616), and include the contact information of the manufacturer, the importer, and the testing laboratory. Most importantly, it must be based on a passing test report from a CPSC-accepted lab. We create a customized CPC for each of our client's orders, ensuring it is properly filled out and signed by an authorized company official. This document is then provided well in advance of shipping, allowing our clients to review it and feel secure in their compliance status before the goods ever leave our factory.

Conclusion

Staying ahead of CPSIA updates for infant sleepwear is a continuous process, but it is fundamental to successful operations in the US market. The key takeaways are the reinforced enforcement of flammability standards (ASTM D6545), the critical importance of accurate tracking labels and documentation, and the non-negotiable need for verified third-party testing. By choosing a manufacturing partner with a proven track record of transparency and compliance, you can transform these regulatory challenges into a competitive advantage, ensuring your brand is synonymous with safety and reliability.

If you are looking for a dependable partner to manufacture CPSIA-compliant infant sleepwear with a seamless process from design to delivery, contact our Business Director Elaine today to discuss your specific needs. Her email is elaine@fumaoclothing.com. Let us help you navigate the complexities of the US market with confidence.