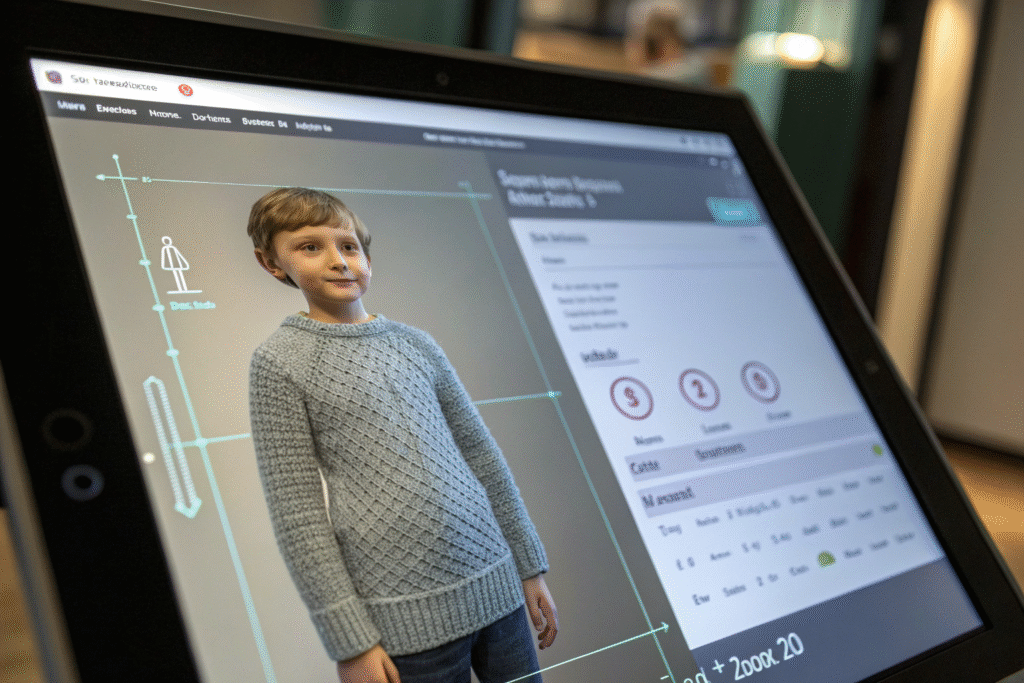

Online shopping for clothing has grown at lightning speed, but one problem has never gone away: size and fit uncertainty. Parents buying children’s wear online often wonder, Will this size “2T” actually fit my toddler, or will the sleeves be far too long? This constant guessing leads to high return rates, wasted time, and frustrated customers. To address this, retailers are investing heavily in 3D virtual fitting technology, which lets shoppers preview how garments will look and fit on digital avatars before making a purchase.

The accuracy of 3D virtual fittings has improved dramatically in recent years thanks to AI-powered size prediction, precise body scanning, and advanced fabric simulation engines. While the technology is not yet perfect—especially for fast-growing toddlers and highly elastic fabrics—it already helps brands reduce returns and boost buyer confidence.

How do 3D virtual fittings work?

The core of 3D fitting technology lies in combining body measurement data with digital garment patterns. This data can be collected in multiple ways: parents may enter manual measurements, take photos with smartphone apps, or even use LiDAR-enabled devices to scan a child’s body within seconds. Once an avatar is created, digital garment files are “dressed” onto it, and advanced physics models simulate how the fabric drapes, stretches, and folds.

What technologies power virtual fittings?

- 3D body scanning: Some scanners capture over 100 reference points in less than 30 seconds, creating avatars that closely match real proportions.

- Fabric physics simulation: Programs like CLO3D, Optitex, and Browzwear account for fabric density, stretch percentage, and weight per square meter to predict drape.

- AI-driven sizing engines: Algorithms compare user data to thousands of previous purchases, offering size recommendations that are statistically more accurate than static charts.

How realistic is the simulation?

For structured garments—jackets, trousers, or dresses—the simulation is highly realistic. A McKinsey Fashion Report noted that leading systems now achieve 85–95% accuracy in predicting garment drape and fit. For example, denim jeans simulated in CLO3D often mirror real-life wrinkle placement at the knees and hips with striking precision. However, accuracy drops for stretchy fabrics such as toddler leggings, where elasticity is harder to model.

How accurate are 3D fittings for children’s wear?

Children’s clothing introduces unique complexities. Unlike adults, kids’ proportions shift rapidly, and growth can make today’s perfect fit tomorrow’s misfit. A sweater designed for a 2-year-old may already be too small within three months.

What makes children’s wear more complex?

- Rapid growth: Toddlers can grow 2–3 inches in a single year, meaning the fitting window is very narrow.

- Difficult scanning conditions: Young children rarely stand still long enough for precise scans, forcing many parents to rely on estimated or averaged measurements.

- Fabric variability: Children’s garments often use stretchy knit fabrics for comfort, but stretch is difficult to model consistently across software platforms.

How reliable is it for parents?

According to research from the Fashion Innovation Agency, virtual fittings for children’s clothing achieve about 80% accuracy when relying on standard size charts and manual measurements. When paired with smartphone scans, accuracy improves, but parents still find it less useful for fast-growing toddlers. For older children (ages 6–12), accuracy is far higher, since growth is more predictable and body proportions are easier to measure.

What benefits do brands gain from 3D fittings?

Even with limitations, the benefits for apparel brands are enormous.

How do fittings reduce returns?

Fit issues account for nearly 70% of apparel returns in e-commerce. Shopify reports that average return rates for online fashion hover around 30–40%, creating logistical headaches and profit losses. Retailers adopting 3D fitting solutions have reduced returns by as much as 20%, saving millions annually in shipping and restocking costs.

How do fittings improve customer trust?

Parents are more willing to buy confidently when they can visualize their child in a garment before checkout. A CLO3D client case study revealed a 30% increase in conversion rates after virtual fitting was introduced. Customers left reviews noting that the fittings “looked almost identical to real-life sizing” and helped them avoid ordering multiple sizes “just in case.”

What are the current limitations of 3D fittings?

While powerful, 3D fittings are not flawless.

What are the main challenges?

- Stretch fabrics: Elastic knits used in toddler sweaters and leggings can stretch differently depending on washing, humidity, and production batches—factors hard to replicate in software.

- Skin and movement modeling: Avatars cannot perfectly simulate how soft baby skin compresses or how fabric shifts when a child bends or crawls.

- Growth factor in kids: No system yet predicts future growth, limiting the long-term accuracy of fittings for infants and toddlers.

- Consumer adoption barriers: Some parents find scanning their child difficult, intrusive, or impractical.

How is accuracy expected to improve?

With the spread of LiDAR-equipped smartphones, more parents will be able to scan children accurately at home. Coupled with AI systems trained on millions of real purchase-and-return datasets, experts expect accuracy to reach 95% or higher by 2028, even for complex fabrics like stretch cotton knits.

Conclusion

3D virtual fittings have proven remarkably accurate, achieving 85–95% precision for structured garments and about 80% accuracy for children’s wear. While not yet perfect—especially with stretchy toddler fabrics and unpredictable growth patterns—they are already transforming the way parents shop. The technology reduces return rates, improves buyer trust, and helps brands cut waste while offering more sustainable online retail.

At Shanghai Fumao, we see 3D fitting as a powerful tool for our international clients. By combining our deep expertise in children’s knitwear manufacturing with advanced 3D simulation tools, we aim to help buyers visualize orders before production, reducing risk and improving decision-making. If you are looking for a manufacturer that embraces both traditional craftsmanship and cutting-edge digital tools, please contact our Business Director Elaine at elaine@fumaoclothing.com to explore how we can support your next apparel project.